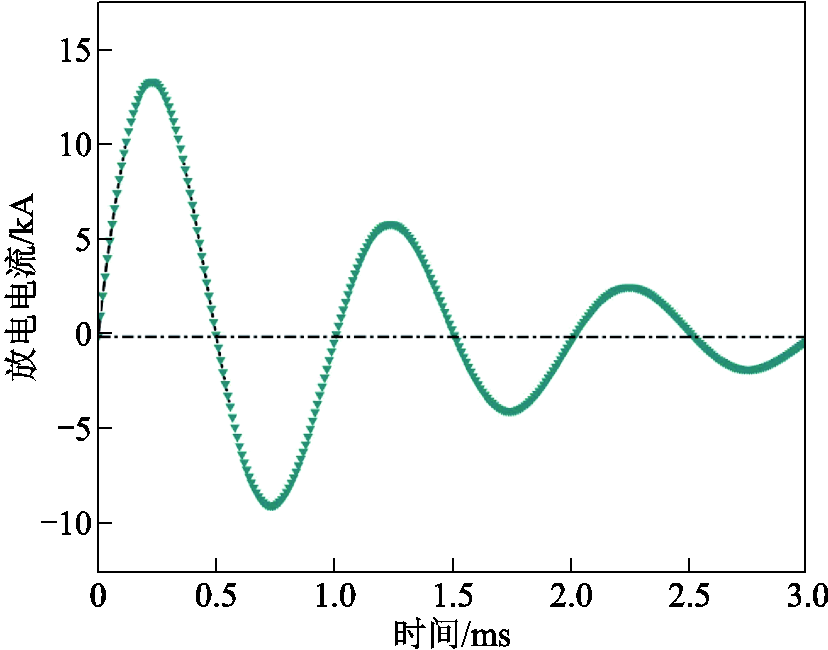

图1 振荡电流波形

Fig.1 Oscillation current waveform

摘要 电磁成形技术是一种典型的高速率电磁脉冲成形技术,可显著地提高材料的延展性,减小工件回弹和起皱,降低设备制造成本。在电磁成形技术发展过程中,电磁成形力场的有效加载和调控颇具挑战,早期的电磁成形方案基本实现工件排斥力成形效果,其电磁力分析中主要以排斥力占据主导,应用有较大的局限性,如今优势明显的组合式电磁成形技术开始进入大众视野。该文在简述电磁成形基本原理及电磁力调控方式的基础上,根据组合式方法应用的不同层面,将近年来涌现的研究成果划分为:驱动线圈组合式、电磁力组合式及工艺组合式三类电磁成形技术,针对每一类技术,分别阐述了其实施原理、技术方案及应用成效,并进一步归纳了不同技术的适用范围及研究重点。最后,在这些研究成果的基础上,对组合式电磁成形技术未来的发展方向进行了展望。

关键词:电磁成形 脉冲磁场 驱动线圈 电磁力 成形工艺

电磁成形(Electromagnetic Forming, EMF)是一种利用电磁力驱动金属材料发生高速变形的先进制造技术。它将脉冲电流通入驱动线圈产生脉冲磁场,变化的磁场在待成形金属材料中产生感应涡流,涡流与磁场共同作用产生电磁力驱动金属材料发生高速变形[1-3],具有抑制起皱、减小回弹等诸多优点[4-6]。与传统机械冲压等成形技术不同,电磁成形可不受传力介质自身特性的限制,电磁力可直接加载,设备工装简单,清洁高效,所使用的电磁力[7]能够在时间和空间上灵活调控,且电磁力为非接触力,可有效地提高工件表面成形质量[8-9]。近年来,轻质合金[10]应用广泛,传统准静态金属加工方式因其自身局限性难以在室温下高效成形,而电磁成形因其极高的应变速率,能显著改善轻质合金材料(如铝、镁、钛等)的成形性能,因而展现出巨大优势[11]。

电磁成形研究初期,缺乏有效的成形力场设计准则,其力场位形相对单一,而且几乎都采用排斥式电磁力[12-14]。如于海平等[15]利用脉冲电磁力研究了铝管缩径及铝、钢管焊接接头的力学性能;李娜等[16]利用脉冲电磁力对铝合金板件进行拉伸试验与有限元模拟;陈石等[17]利用排斥式电磁力对铝合金曲面件进行电磁校形实验。究其原因,是由于工件上的感应涡流与原生磁场高度耦合,根据楞次定律,其最终效果体现为排斥式。此外,由于线圈形式单一,多为单个螺线管,产生单一的力场位形给电磁成形的应用带来了较大局限性。因此,许多专家学者在后续研究中通过改变成形线圈结构[18]或者利用集磁器[19-20]改善磁场分布,进而改变成形力场以获得更均匀的电磁力。如:G. S. Daehn等[21]提出一种匀压力驱动线圈,使得工件成形更为均匀;Lai Zhipeng等[22]设计了一个高强度线圈,以高达155 kJ的放电能量大尺寸圆形铝板实现了翻边,验证了电磁成形技术对大尺寸板材工件的有效性;邱立等[23-24]提出了凹形/凸形驱动线圈,提高了管件成形的均匀度和成形质量。

近年来,航空航天、汽车工业领域对大尺寸工件整体化成形及微小结构复杂零部件精细化成形提出了更高的要求,传统电磁成形在制造具有大变形量、深腔、局部圆角/凸台等特征钣金零件上的难度大幅提升,激发了组合式电磁成形技术的形成。随着新一代多特征耦合的钣金零件整体化、轻量化等制造要求的提高,采用组合式电磁成形技术的优势愈发显著,以华中科技大学李亮教授[25]领衔的973计划“多时空脉冲强磁场成形制造”项目,围绕着大尺寸工件(如:1 000 mm级铝合金球面板材[26-27]、火箭燃料贮箱箱底壳体[28])展开了多级多向脉冲强磁场组合式电磁成形力场调控、成形装备研制等研究,提出了双频电流法[29]、多线圈多电源轴径双向加载电磁成形[27]、基于集磁器[30-31]的磁场调控电磁成形技术等先进技术,催生了更为多样的组合式电磁成形技术研究,为电磁成形开辟了新的方向。

组合式电磁成形技术,是通过线圈、力场及成形工艺的搭配,使得磁场位形和成形力场更为多样,以期实现更灵活、更高效精准的成形。通常利用多个线圈的组合,以灵活改变磁场位形;还可利用多种不同电磁力的辅助,进行不同向的合力成形;亦可利用电磁成形工艺同其他成形工艺组合,实现最佳成形效果。

基于此,本文在简述电磁成形技术原理的基础之上,对驱动线圈组合式电磁成形技术、电磁力组合式电磁成形技术以及工艺组合式电磁成形技术三大方面进行综述,分别阐述三类情况的实施原理、技术方案、应用案例,并进一步归纳其技术特征、适用范围及研究方向等。最后,在现有组合式电磁成形技术的基础上,对亟待解决的问题进行了归纳,并对未来的发展方向进行了展望。

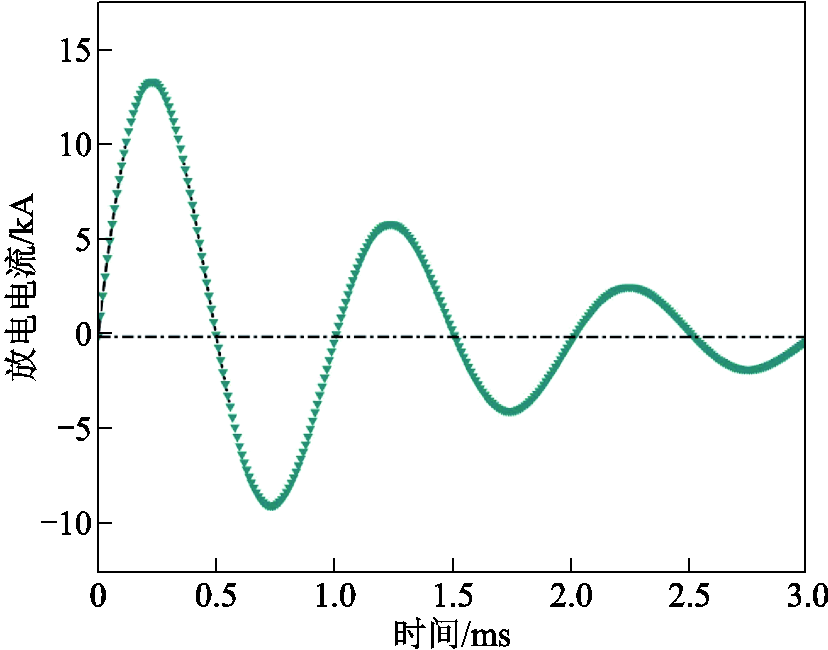

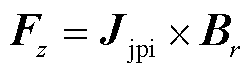

在传统电磁成形方案中,电容、放电电路以及线圈构成等效RLC回路,放电开关闭合的瞬间产生振荡衰减的脉冲电流[32-33],如图1所示。在电磁成形过程中,脉冲电流起主导作用的是第一个半波。因此,在放电电路中并联续流回路[29]以保证电流不振荡,同时能够有效降低线圈温升[34-35]。放电电路等效示意图如图2所示。在目前使用的放电电路中,将线圈与工件等效为RL电路,并引入互感系数M,完整考虑工件几何变化和形变速度对电路、磁场、结构场产生的影响。

图1 振荡电流波形

Fig.1 Oscillation current waveform

图2 放电电路等效示意图

Fig.2 Equivalent diagram of discharge circuit

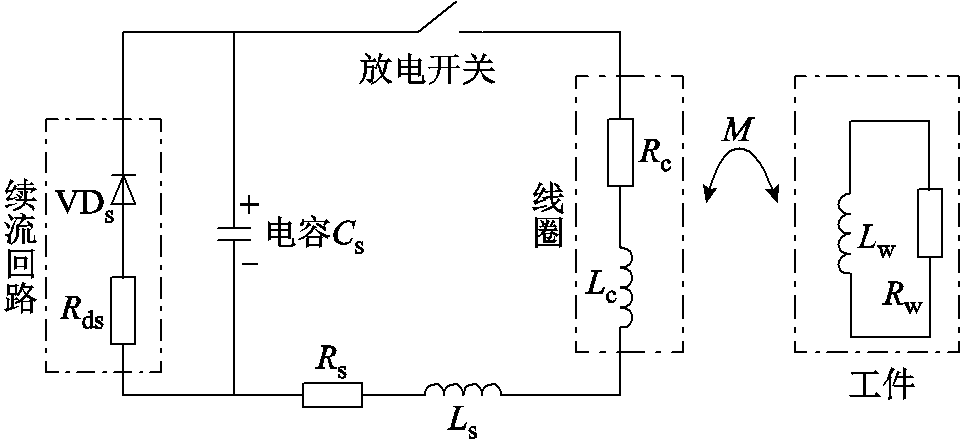

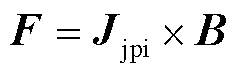

由电磁成形原理可知,作用在工件上的电磁力密度可以表示为

(1)

(1)

式中,Jjpi和B分别为工件上感应涡流密度和磁通密度。根据以往研究,将电磁力分为轴向电磁力及径向电磁力。

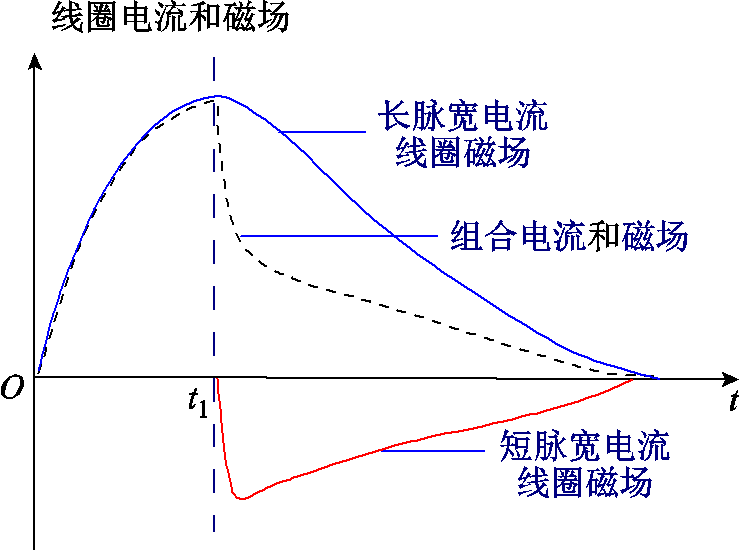

(2)

(2)

(3)

(3)

式中,r、z分别为径向分量以及轴向分量。板件以径向磁场与环向涡流耦合的轴向电磁力为主,如式(2);而管件以轴向磁场与环向涡流耦合的径向电磁力为主,如式(3)。

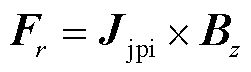

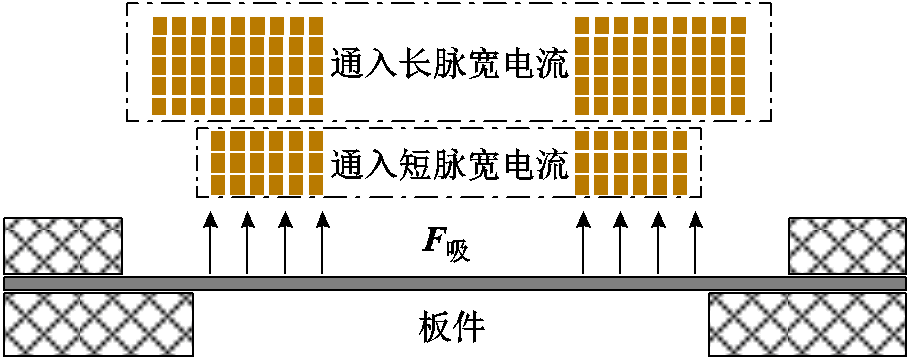

由上述方程可知,当磁场方向不变时,脉冲电磁力方向主要取决于感应涡流方向,Deng Jianghua等[36]针对平板线圈中放电波形对工件电磁力的影响,提出了采用缓慢上升沿、快速下降沿的脉冲电流波形,使工件上产生反向感应涡流用于吸引式电磁力。但由于平板驱动线圈具有一定局限性,故Cao Quanliang等[37]和Xiong Qi等[38]通过将组合电流通过时序控制通入同一成形线圈,相继开展了板件和小管件的电磁吸引力成形研究。两种方案中所用双频电流法如图3所示。

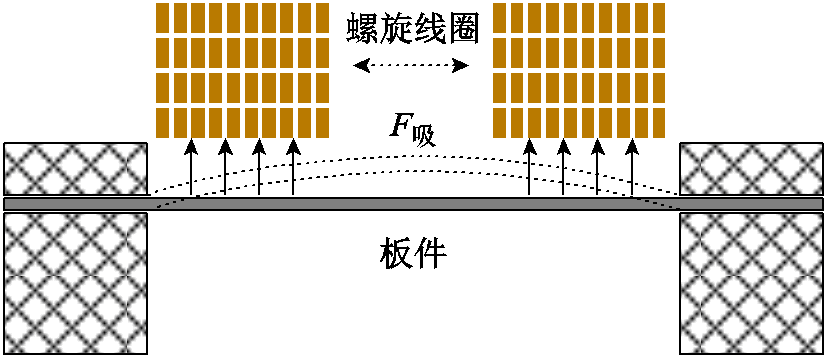

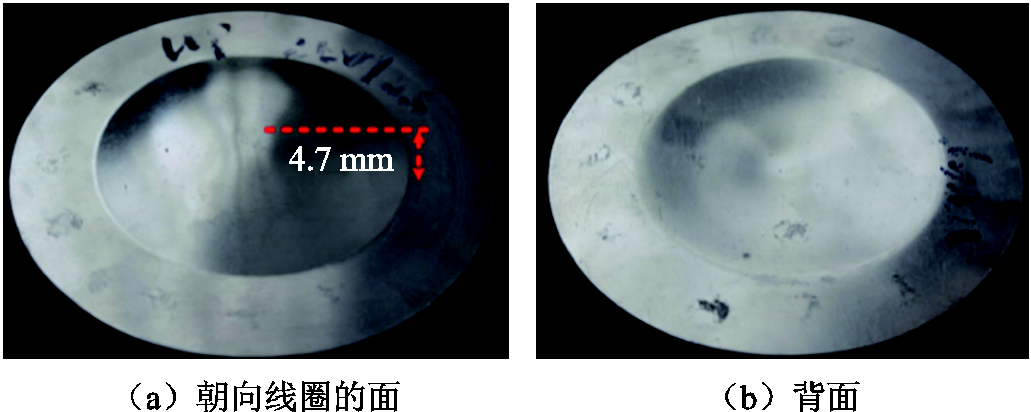

由Cao Quanliang等[37]提出的板件吸引式电磁成形方案如图4所示,实验结果如图5所示,初步验证了吸引式电磁成形的可行性,且此方案可应用于难以拆卸、需要高表面质量的钣金件成形和修复,如汽车车身凹痕修复等。

图3 长、短脉宽的电流和磁场波形

Fig.3 Current and magnetic field waveforms with long and short pulse widths

图4 板件吸引力成形示意图

Fig.4 Schematic diagram of attractive forming of plates

图5 板件吸引力成形实验图[37]

Fig.5 The deformed sheet with front and back faces[37]

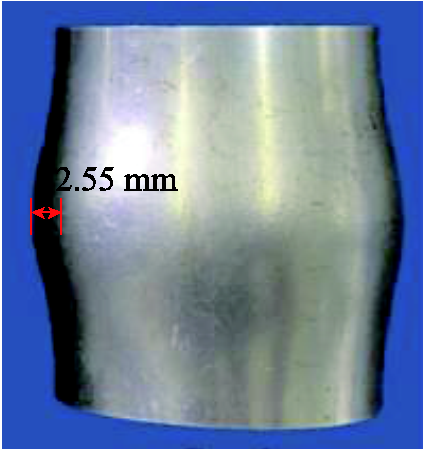

对于小管件而言,若采用传统的排斥力方案,将驱动线圈置于管件内部,对线圈结构强度的要求十分严苛,且线圈难以绕制,因此难以通过排斥式电磁成形实现小管件的胀形成形。为解决这一问题,Xiong Qi等[38-39]利用双频电流法,将吸引式电磁力应用于微小管件成形。在经过详细的仿真分析之后,针对直径为28 mm、长度为39 mm、厚为1 mm的AA1060-O铝合金管件,进行了一系列成形实验,实验结果如图6所示。实验利用长、短脉宽合成电流产生的吸引式电磁力使管件胀形2.55 mm,获得了较好的成形效果。

图6 管件吸引力成形实验结果[39]

Fig.6 Results of attractive forming of tube expansion[39]

以上两种方案中均采用单个成形线圈,虽可以实现吸引力成形,但电流需与放电参数相互匹配,放电条件严苛。并且由于通入线圈中的两套脉冲电流均属强电流,线圈温升严重,对单一线圈的制造要求极高。熊奇等[40]在电磁成形中引入集磁器辅助,明显改善了工件局部变形量,使得线圈的热量损耗减小[41],但成形力场位形仍单一。因此,优势明显的组合式电磁成形技术成为当下的热门研究。为此,本文将现有组合式电磁成形技术分为:驱动线圈组合式电磁成形技术、电磁力组合式电磁成形技术、工艺组合式电磁成形技术,逐一阐述评价,进一步概括电磁成形技术的优点及亟待解决的问题。

在驱动线圈组合式电磁成形技术中,驱动线圈提供了成形所需电磁力,并发挥了改善电磁力分布的作用。由于单个线圈强度有限且产生的电磁力在工件成形中较不均匀,因此,采用更加灵活的组合式线圈电磁成形方法成为不二之选。

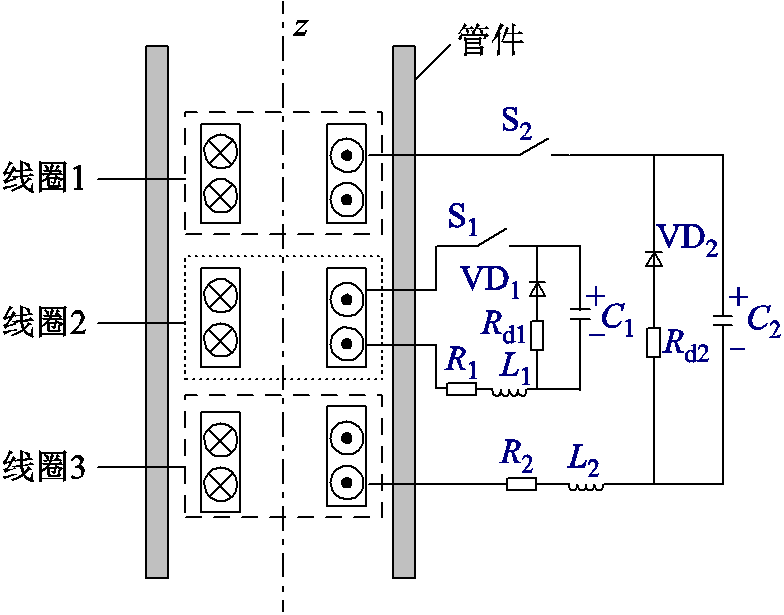

2.1.1 三线圈提升管件成形均匀度

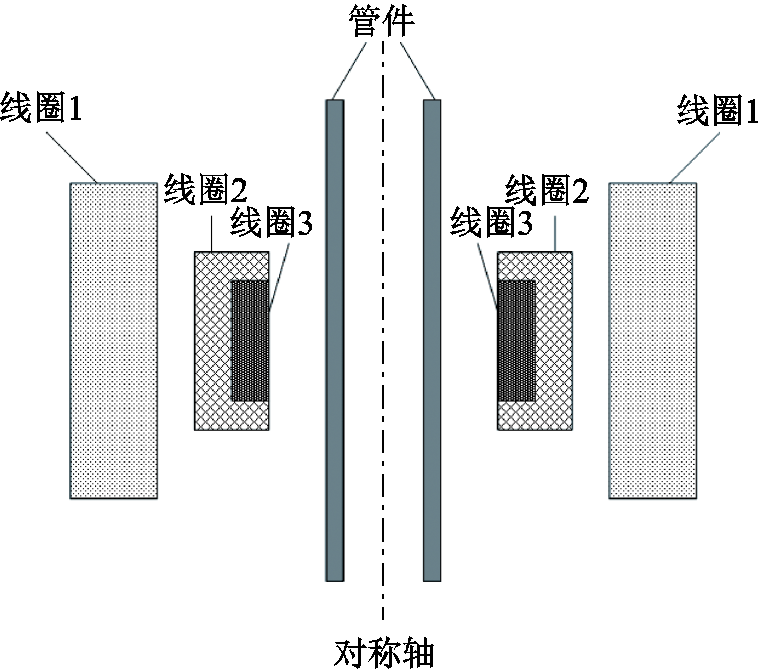

电磁成形技术线圈-工件系统的配置一旦确定,电磁力分布相对固定,难以控制变形工件的形状、成形范围及均匀度。从此角度出发,Ouyang Shaowei等[42-43]提出了一种三线圈管件电磁成形方案,如图7所示。新的线圈由三个同轴线圈组成,将上、下线圈串联通入同一脉冲电流,通过调整线圈的放电电压比,实现电磁力分布的改变,调节管件成形效果。除此之外,通过调节电源参数可直接改善管件成形均匀度。

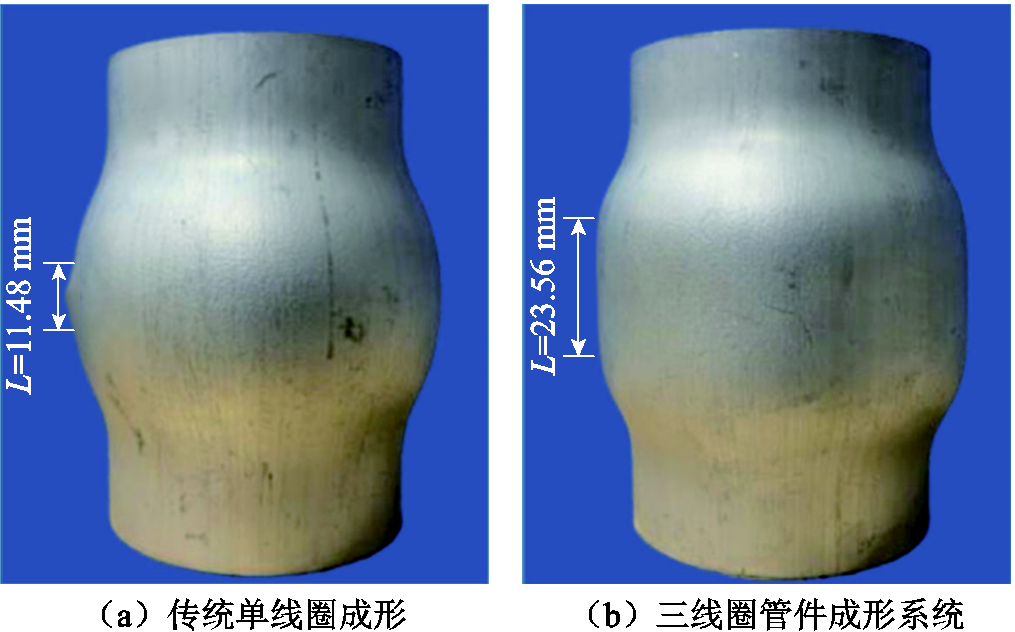

研究针对直径76 mm、长120 mm、厚2 mm的AA6061-O铝合金管件进行实验,实验结果如图8所示。为了进一步对比,分析了传统单线圈系统管件成形行为,使两种方案获得相同的中心最大位移。结果表明(L越大,均匀度越高[43]),三线圈系统成形均匀度远大于单线圈,并且通过改变放电参数可直接调节管件胀形和缩颈形变,这是单次放电的单线圈系统所不能做到的。此方案从改变电磁力分布的角度思考成形方案,而目前从该角度出发的研究虽有相似的部分[44-45],但均未有方案颠覆式地改变电磁力分布,故依然是未来电磁成形的重要研究方向。

图7 三线圈管件成形系统

Fig.7 Three-coil tube forming system

图8 三线圈管件成形实验结果对比[43]

Fig.8 Comparison of experimental results for three-coil tube forming[43]

2.1.2 双驱动线圈电磁渐进成形

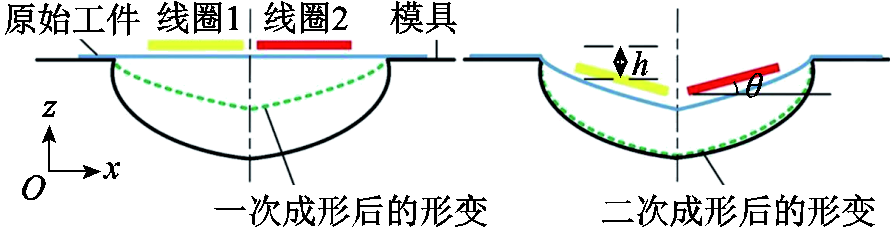

Cui Xiaohui等[46-47]基于电磁成形和渐进成形提出电磁渐进成形(Electromagnetic Incremental Forming, EMIF)的概念,基本成形思路为:采用小型线圈对大尺寸工件局部放电,通过改变驱动线圈的放电路径及放电参数等积累成形,最终实现大型工件电磁成形。进一步地,Cui Xiaohui等[48]在电磁渐进成形基础上提出两步电磁成形,利用平板螺线圈初次成形后,更换与工件最终成形轮廓形状相似的螺线管线圈,进行电磁校形二次成形,实现大板件局部倾斜翻孔及长孔翻边[49]。与此同时,Li Jianjun等[50-53]对单线圈的电磁渐进成形过程中成形深度、成形均匀度、应力波传播规律等动态变形行为进行系统研究,为大尺寸双线圈电磁渐进电磁成形研究奠定了基础。

Liu Xianlong等[54]提出双驱动线圈的电磁渐进成形,利用两个相同的平板螺线圈在三维空间中移动,针对直径690 mm、厚度2 mm的AA5052-O铝合金板件分析了顺序移动放电和间隔移动放电下的成形均匀性,实验装置轴向上最大移动距离为1 m,线圈旋转装置最大角度分别为90°和360°。其基于双线圈的EMIF分为两层成形,第一层和第二层的成形原理相同,两个线圈的中心距离均保持为200 mm。其中,第一层仅在xy平面平移,第二层在z轴方向有下降与倾斜,下降的距离为h=30 mm,倾斜角度为θ=10°,如图9所示。经过两层成形后,成形深度为54.50 mm,相较于单线圈放电存在成形不均匀的问题,双线圈的对称结构,无需考虑材料径向流动不均匀,显著提高了成形均匀性,贴模质量更好。虽利用双线圈使得成形质量有较大的提升,但目前对双线圈成形的动态变形过程的研究较少,缺少后一次放电给前一次形变造成影响的研究,后续将加强这一研究,进一步推动EMIF技术的发展。

图9 电磁渐进成形双线圈两层成形原理

Fig.9 Electromagnetic progressive forming double coil two layer forming principle

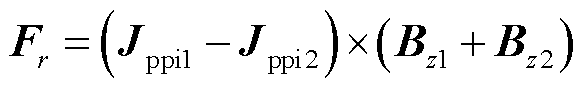

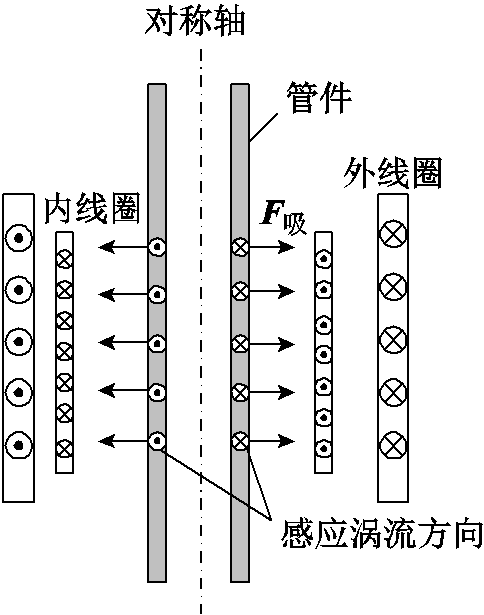

2.1.3 内-外双线圈管件电磁成形系统

基于单线圈管件电磁成形系统,Li Xiaoxiang[55]提出内-外双线圈管件成形系统,如图10所示,外线圈通入长脉宽电流,主要提供背景磁场,内线圈通入短脉宽电流,主要提供涡流;内外线圈通入的电流方向相反,内外线圈在管件周围产生的磁场方向相同,在管件上感应的涡流方向相反,此时管件的径向电磁力密度可表示为

(4)

(4)

式中,Jphi1和Jphi2分别为内线圈和外线圈在管件上产生的环向感应涡流;Bz1和Bz2分别为内线圈和外线圈在管件周围区域产生的轴向磁通密度。

图10 内-外线圈管件成形系统

Fig.10 Inner-outer double coil tube forming system

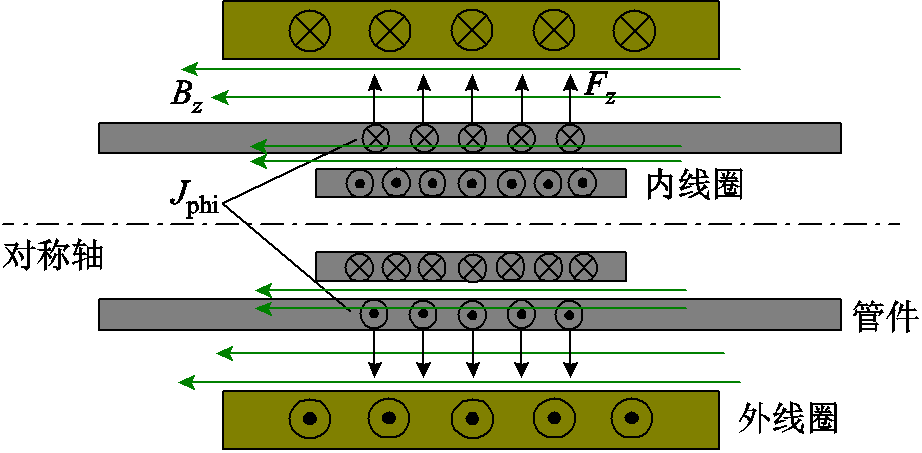

内-外双线圈结构实现了工件涡流与磁场的解耦,提高了电磁成形的灵活性和可控性。在此基础上,Zhang Wang等[56]提出在内-外双线圈中同时通入大小相等、方向相反电流的方案,发现内-外双线圈成形系统可以动态调节管件受到的径向电磁力。这是因为,当管件变形区域越大、越靠近外线圈时,外线圈的感应涡流会变大,根据式(4)可知,管件变形区域的电磁力会减小,从而实现自动反馈调节,显著提高成形均匀度。

该方案针对直径79 mm、厚2 mm、长180 mm的AA6061-O的铝合金管件进行实验,实验结果如图11所示。在实验中,单线圈和双线圈系统的管件成形均匀度分别为20.5%和75.6%,实验和仿真结果之间的误差分别为1.9%和1.7%。

图11 单线圈及内-外双线圈管件成形结果对比[56]

Fig.11 Comparison of single coil and internal-external double coil tube forming results[56]

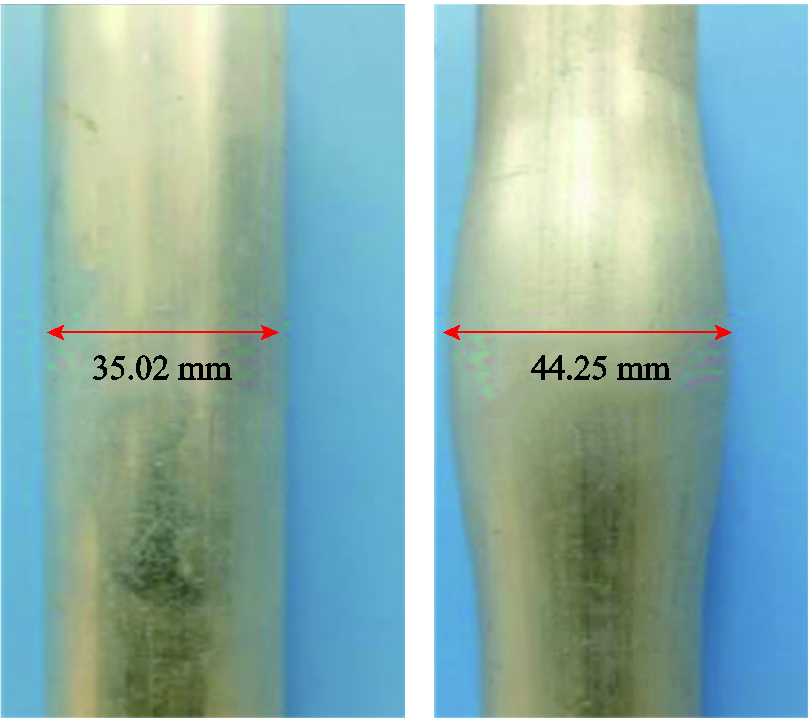

2.2.1 双线圈-管/板件吸引力成形

前述表明,单一线圈工作要求两套电源的放电参数严格匹配,放电条件严苛且灵活性较差,为解决此问题,欧阳少威[57]提出了双线圈方案,如图12所示。当内线圈触发后,管件上的涡流迅速反向,产生吸引式电磁力,此方式将涡流和磁场单独控制,解决了双脉冲电流下参数的严苛配合的问题。该方案针对直径35 mm、厚1 mm的AA6061-O的铝合金管件进行实验,实验结果如图13所示,该方案成功地使管件吸引力径向胀形9.23 mm,而此时的径向电磁力达到6×109 N/m3。

图12 基于双线圈管件电磁吸引力成形示意图

Fig.12 Schematic diagram of electromagnetic attraction forming based on double coil tubing

图13 双线圈管件电磁吸引力成形实验结果[57]

Fig.13 Electromagnetic tube expansion with double coil[57]

文献[57]证实了双线圈产生吸引式电磁力的有效性。而后,熊奇等[58]将双线圈吸引力成形方案应用于板件成形,建立双线圈板件吸引力电磁成形仿真模型,如图14所示。并在研究中进一步发现虽然双线圈方案相较于单线圈更加灵活,但对于板件类工件,会造成同一时间在工件不同位置存在方向相反的感应涡流,故将此称为“涡流竞争”,方案使工件产生吸引力的同时,局部仍然存在排斥力,造成最终成形的凹痕缺陷。

图14 双线圈吸引式板件成形系统

Fig.14 Double-coil attraction plate forming system

故研究进一步对线圈结构进行合理设计,通过改变通入长脉宽电流的线圈层数来消除涡流竞争引起的板件凹痕;且当通入长脉宽电流的线圈径向层数略大于通入短脉宽电流的线圈径向层数时,能优化板件吸引力成形的均匀度。但在吸引力方案中,由于工件会与线圈内层发生碰撞,成形效果并不理想。为避免潜在碰撞,会扩大线圈与工件间的距离,随着距离的扩大,电磁力会急剧减小,这是目前需要权衡的问题。

2.2.2 双线圈电磁吸引力翻边

铝合金材料在室温下成形性能较差,采用传统机械力在进行工件翻边、扩口及收缩等制造时,工件回弹严重、易破裂且表面质量不佳[59-60]。与之相比,张文忠等[61]发现电磁翻边具备独特优势,高应变率增加了工件的可塑性。同时,无接触式的、分布均匀的电磁力加载改善了工件起皱、回弹等现象[62],以大型薄壁构件火箭燃料贮箱为例,贮箱箱底局部需要加工出翻边特征以便于与周围管路连接[63-64],对于火箭燃料贮箱箱底等大型曲面薄壁结构的高精度翻边,电磁力的上述技术特点恰好能够解决目前传统工艺难以解决的问题。

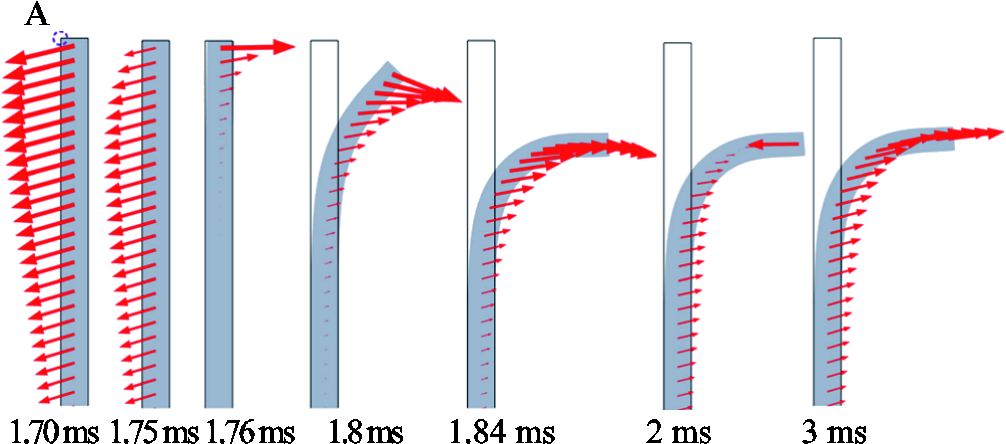

基于此,Xiong Qi等[65]提出一种双线圈吸引式管件电磁翻边方案,将两个独立的驱动线圈置于管件端部,直接避免小管件线圈难以内置的问题。该案中,两个线圈分别由两个电源放电(长脉宽电流通入外线圈,短脉宽电流通入内线圈),如图15所示。起初管件端部会先受到驱使管件向内形变的电磁力,在短脉宽电流导通之后,管件受到吸引式电磁力并在此力作用下完成翻边,如图16所示。该方案对于管件翻边的有效性是显而易见的。

图15 电磁翻边系统示意图

Fig.15 Diagram of the electromagnetic flanging system

图16 仿真示意图[65]

Fig.16 Diagram of the simulation[65]

吸引式电磁力使管件翻边,既解决了线圈无法内置的问题,又解决了管件吸引式翻边带来的潜在碰撞问题,该方案大大降低了对成形驱动线圈的要求。

驱动线圈组合式的电磁成形技术,究其根本是电源及线圈问题的分解。由于成形需求增长,电源容量亦增加,大容量电源放电时对线圈强度也是一大考验。在单驱动线圈方案暂无法解决此问题的情况下,驱动线圈组合式电磁成形技术巧妙地中和了对线圈严苛的要求。采用此方式既降低了对于线圈强度、参数的配合控制的高要求,又提高了方案的灵活度,拓宽应用场景,降低应用要求。

前文所述方案均从驱动线圈相互组合以提供成形力及改善力的分布着手,力的施加都是单一方向、单一类型(吸引力或排斥力),即电磁力的组合作用并未着重突破。实际上,电磁力不仅可作为成形力,还可作为辅助力;不仅可以单方向,还可多向加载成形。故本节聚焦电磁力组合式成形技术,将现有新型技术进行归纳。

最初的电磁力组合式电磁成形技术为周中玉[66]提出的双级线圈径向驱动孔强化方案,即通过在孔边产生径向电磁力,提高孔件疲劳寿命。

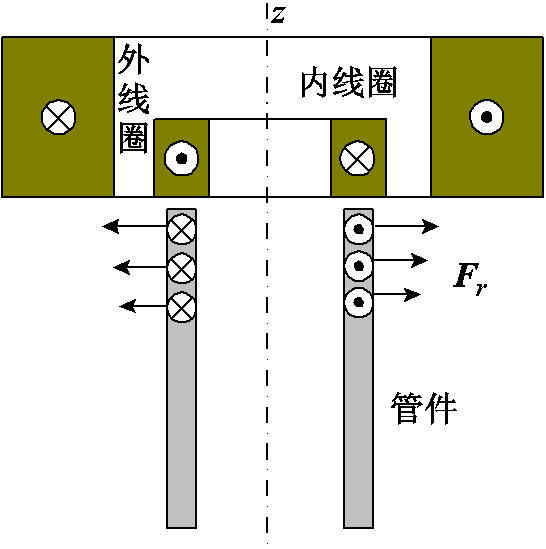

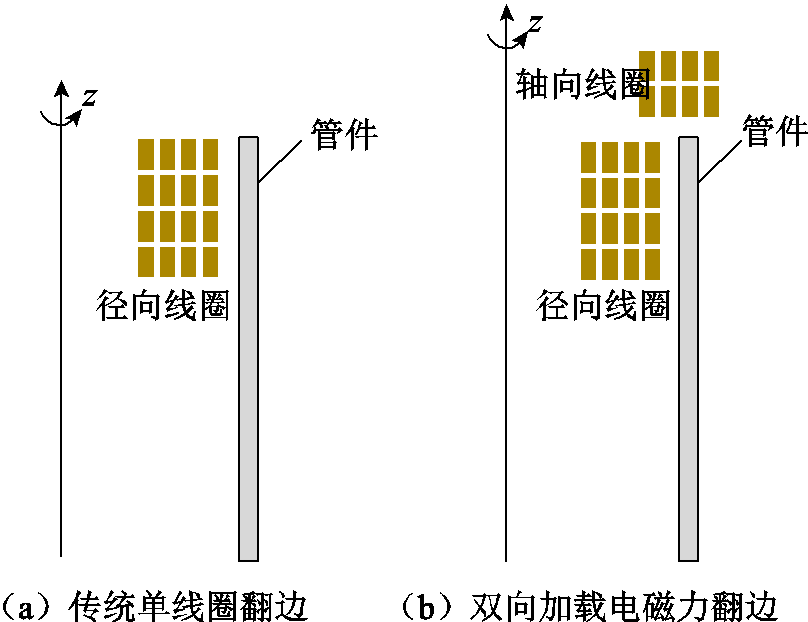

Qiu Li等[67]将此轴径双向加载的思路应用于管件成形,显著提高了管件的成形性能和成形极限。前文所述的电磁翻边方案中,电磁力为单向加载的,而在翻边过程中会同时发生径向胀形与轴向弯曲,故张望等[68]将双向加载思想应用于电磁翻边中。其基本思路为:在传统单线圈管件电磁翻边的基础上,在管件端部增加提供轴向力的轴向线圈进行优化,如图17所示。

图17 管件电磁翻边示意图

Fig.17 Schematic diagram of electromagnetic flanging

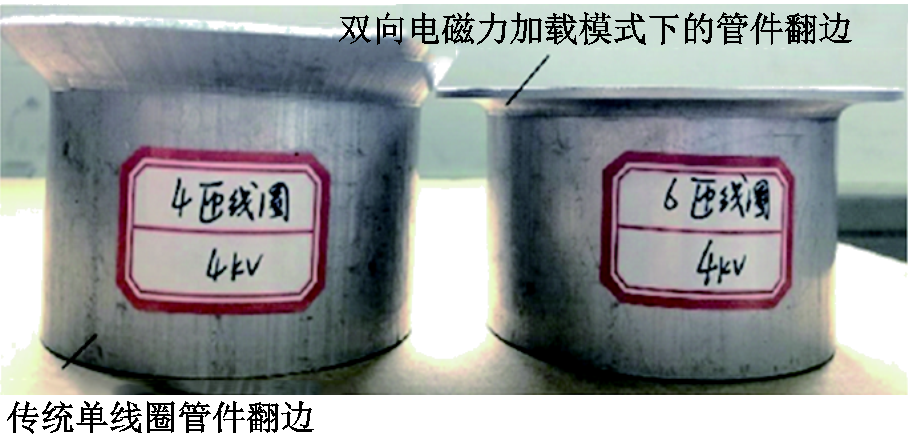

针对直径为79 mm、长度为65 mm的AA6061-O的铝合金管件,分析了两种不同加载模式下,管件的形变情况:轴向线圈所产生的向下的排斥力使管件的翻边效果得到很大的提高;并且在双向加载模式中,即使在加载时提供的径向电磁力较小,由于拥有轴向力的加持,同样也能够取得良好的翻边效果;对比实验下的翻边角几乎达到90°,不同方案下的实验效果如图18所示。

图18 不同方案下的实验效果图[72]

Fig.18 Tube forming profile under different electromagnetic force loading modes[72]

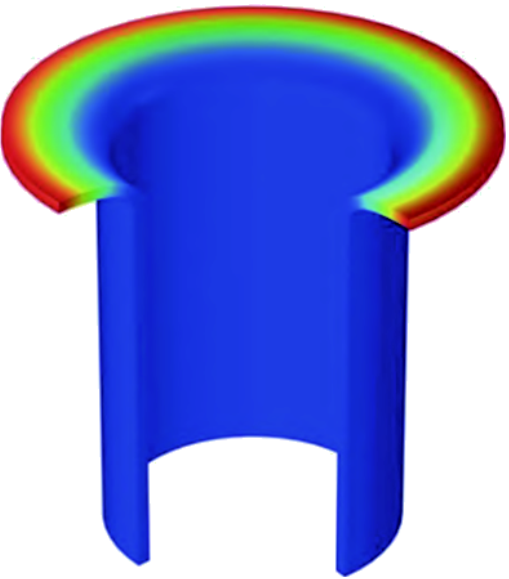

邱立等[24]还提出了凸型线圈双向电磁力加载的管件电磁翻边成形方案,该方案考虑了径向电磁成形力对管件产生向外的扩径胀形以及轴向电磁成形力对管件产生向下的翻边角度,凸型线圈施加了双向成形力加载管件电磁翻边,促进了翻边变形时管件的轴向流动,改善了管件的电磁翻边质量。李盛飞等[69]引入了阶梯型集磁器,将其置于管件和驱动线圈之间,增大了电磁力轴向与径向的双向分量,使得管件端部的形变更加明显,正因为电磁力分量大小发生变化,且其轴向电磁力变化幅度更大,使电磁力的作用方向发生了改变,也使管件的翻边角度达到90°。管件电磁翻边形变示意图如图19所示。

图19 管件电磁翻边形变示意图[69]

Fig.19 Electromagnetic flanging deformation diagram of pipe fittings[69]

本节强调电磁力作为成形驱动力从空间方向上(轴向和径向)的组合,目前双向加载式管件翻边技术面临的主要技术难点有:小尺寸(直径较小)管件翻边时因轴向电磁力的挤压容易发生变形失稳、畸变等问题。

在采用螺线管驱动线圈实现管件电磁成形时,端部效应会导致管件的轴向变形不均匀。Qiu Li等[23]提出用一种凹型驱动线圈代替螺线管线圈,以削弱管件中部径向电磁力,提高管件成形均匀度的方法。但减少线圈中心的匝数会导致耦合效率和能量利用率的降低,线圈在实际绕制时比较困难。

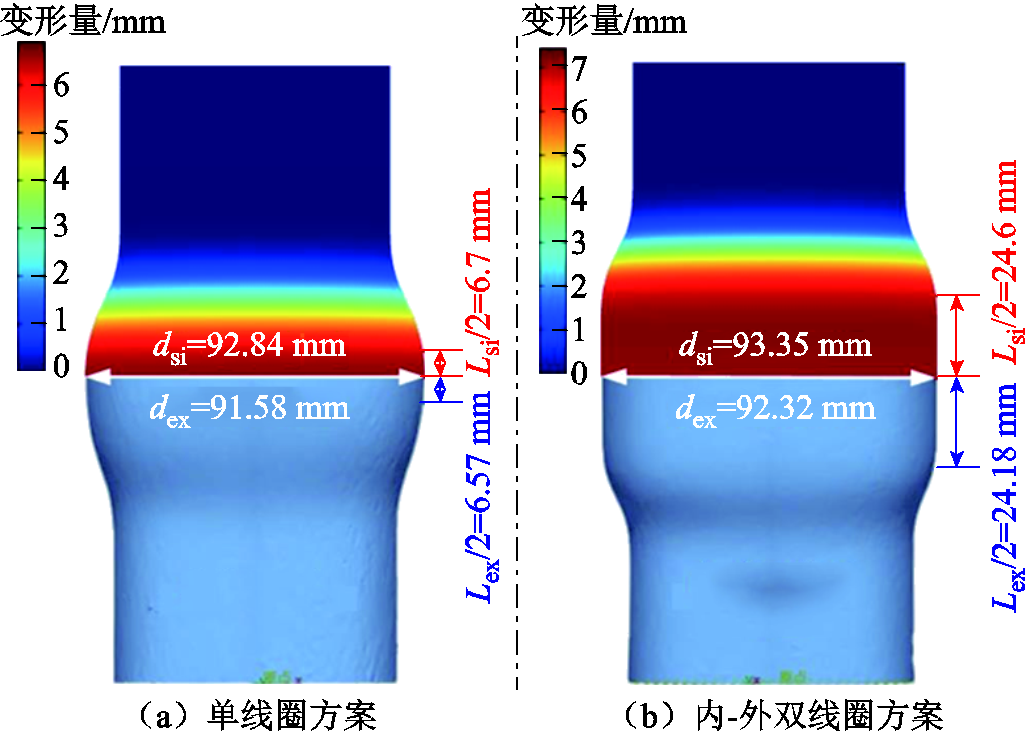

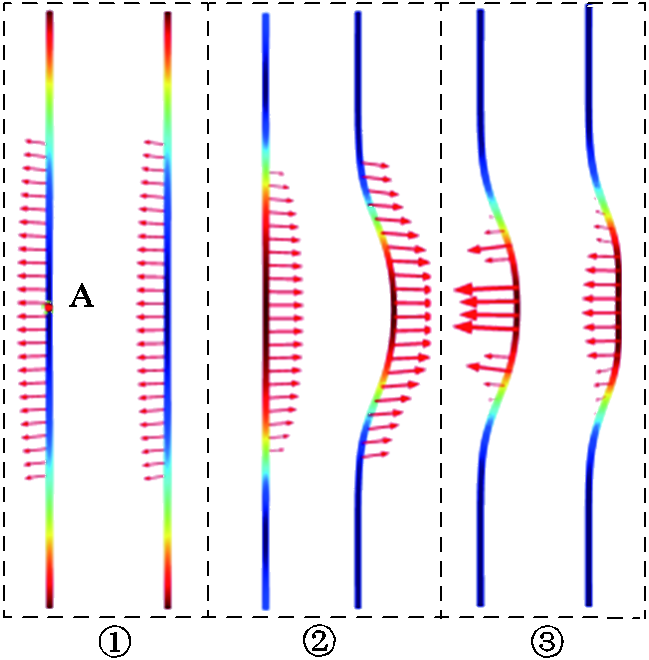

针对上述问题,Xiong Qi等[70]提出了一种三线圈两步法成形的管件成形方案,利用吸引力加排斥力的组合式电磁力,改善管件的轴向均匀度。成形方案如图20所示,其基本思路为:利用长、短脉宽电流组合通入线圈1、2,在管件上产生吸引式电磁力,先使管件发生吸引式形变,待成形结束后,将短脉宽电流通入线圈3,而在管件上产生径向向内的排斥式电磁力,将“尖峰式”管件成形部分向内成形,以此改善管件轴向变形不均匀。

图20 三线圈两步法管件成形方案

Fig.20 Three coil two-step pipe fitting forming scheme

管件受力示意图如图21所示,针对长90 mm、直径40 mm、厚1 mm的AA6063-T83管件进行了仿真分析,从图中能够清晰地看出管件上的受力分为三个阶段:①长脉宽电流通入线圈1,在管件上产生部分排斥力;②短脉宽电流通入线圈2与长脉宽电流配合产生吸引力;③短脉宽电流通入线圈3产生径向向内的排斥式电磁力;此方案下的管件轴向成形均匀长度达到11.63 mm,同参数下相比于传统双线圈吸引力成形[70]方案,均匀度优化了211%。

图21 管件受力示意图[70]

Fig.21 The distribution of Lorentz force[70]

此方法创新性地应用吸引力加排斥力的组合式电磁力成形,扩充了组合式电磁力电磁成形方案的组合形式,吸引力与排斥力相结合的思路也为未来研究给出了新的思路。

电磁力不仅可以作为电磁成形过程中的成形驱动力还可以作为压边力/送边力,此时电磁力不再局限于成形的形腔区域,还能在边缘或法兰区域提供辅助力,更进一步地改善成形效果。

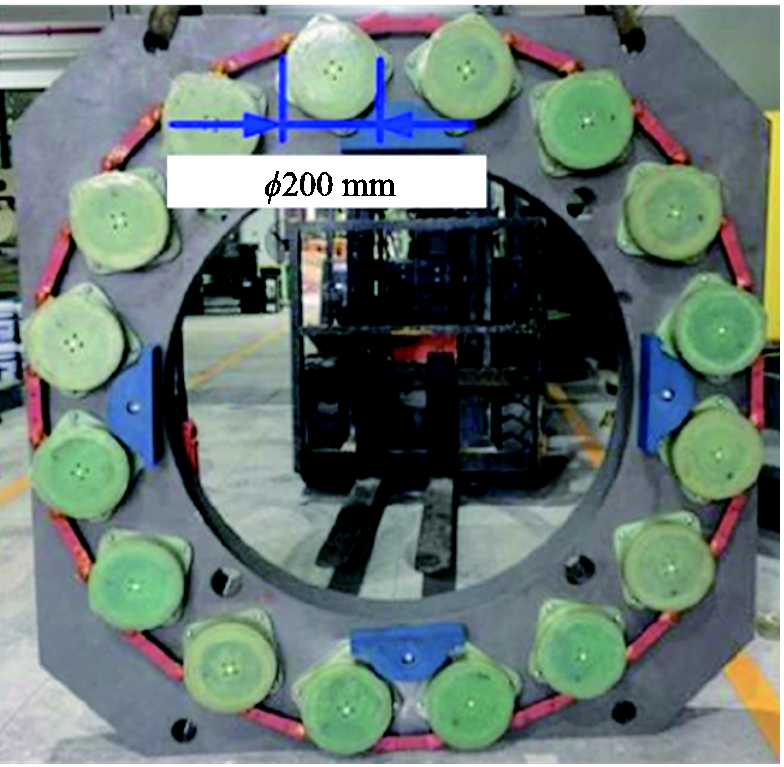

熊奇[26]通过实验验证了电磁成形在大尺寸板件成形方面的成形能力。Lai Zhipeng等[22]针对640 mm的板件验证了电磁整体成形大尺寸铝合金构件的潜力。成形过程中为了防止起皱,需要对工件施加一定的压边力[71]。在此基础上,赖智鹏[27]针对直径为1 378 mm的大尺寸板件提出了电磁吸引式柔性电磁压边系统。其中,成形力用于驱动工件变形,压边力则用于控制法兰材料流动,产生压边力的线圈之间的相互作用力实现了自平衡,无需额外的约束,实现了对成形力和压边力的精确调控[72]。Huang Yujie等[73]也采用类似方法,实现了单线圈排斥力的板件固定。刘宁[28]搭建了柔性电磁排斥式压边电磁成形系统,单次放电实现了直径1 378 mm、厚度4 mm大尺寸铝合金壳体件的电磁整体成形,其中,成形深度大于310 mm,成形件与模具轮廓的最大尺寸偏差小于10 mm,最大减薄率小于15%,满足成形性能要求。排斥式压边电磁成形系统的能量利用率更高,多个互相串联的模块化小线圈降低了线圈绕制难度、便于装卸,线圈实物如图22所示。这种压边方式对大尺寸板件整体成形设备的轻量化、小型化具有重要意义,使得大尺寸板件电磁成形研究达到一个新的高峰。

图22 线圈实物[28]

Fig.22 Physical diagram of the coil [28]

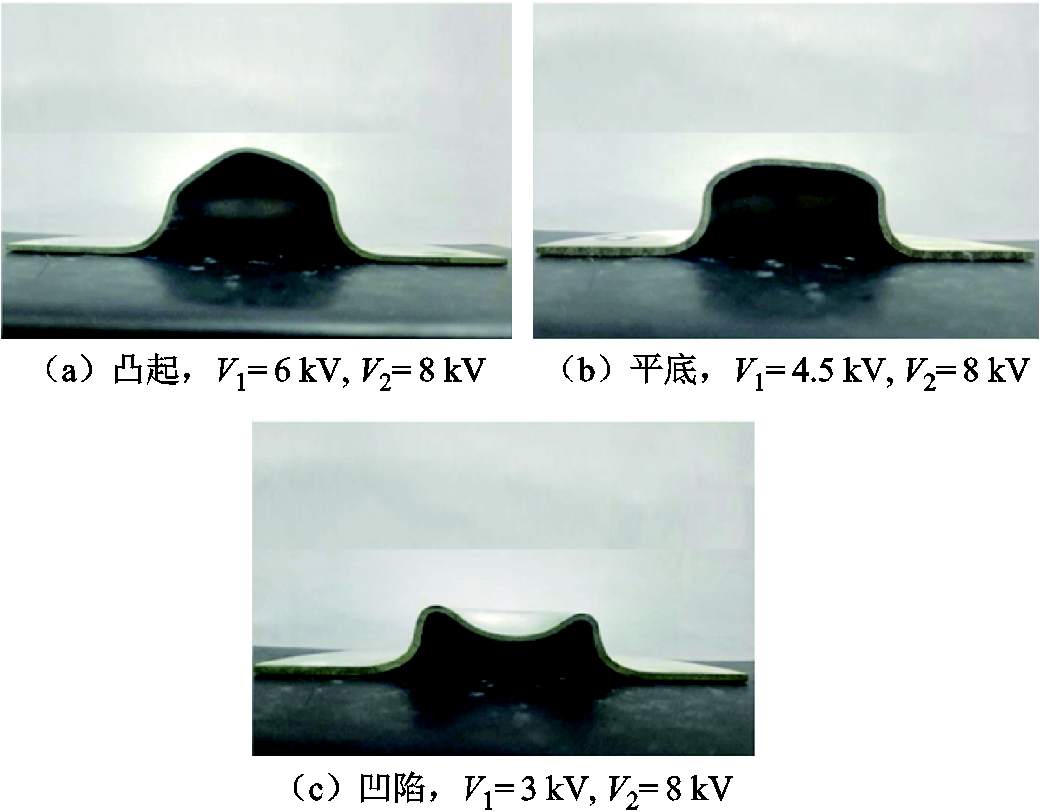

Lai Zhipeng等[74]还提出了径向电磁送边的思想,并将其应用于板件成形,加载多向电磁力载荷,径向电磁送边力加强了板料径向流动,避免了板件成形过程中由于轴向力(单向)过大,易出现板件破裂的问题,并通过实验使板件成形深度由传统成形的8.44 mm,增加到20.28 mm,实现了拉伸比达3.25的筒形件的成形。Lai Zhipeng等[75]进一步研究了所提工艺的变形行为,发现通过径向送边力的控制加强了材料的流动,形变可以从圆锥形逐渐变为圆柱形。Chen Meng等[76]探讨了放电电压组合中通过双线圈电磁场控制变形的潜力,采用不同等级电压配合实现了底部凸起、平底或凹陷的变形曲线。不同电压下实现的工件变形如图23所示。随后其对深腔成型的动态变形行为进行了数值分析,揭示了改善减薄和成型精度的内在机制,对比传统电磁成形,径向送边力的引入使深腔工件的成形性能得到改善,厚度分布更加均匀,最佳模具装配间隙缩小为0.35 mm[77],突破了深腔构件亚mm级别精度。

图23 不同电压下实现的工件变形[76]

Fig.23 Three typical deformed workpieces[76]

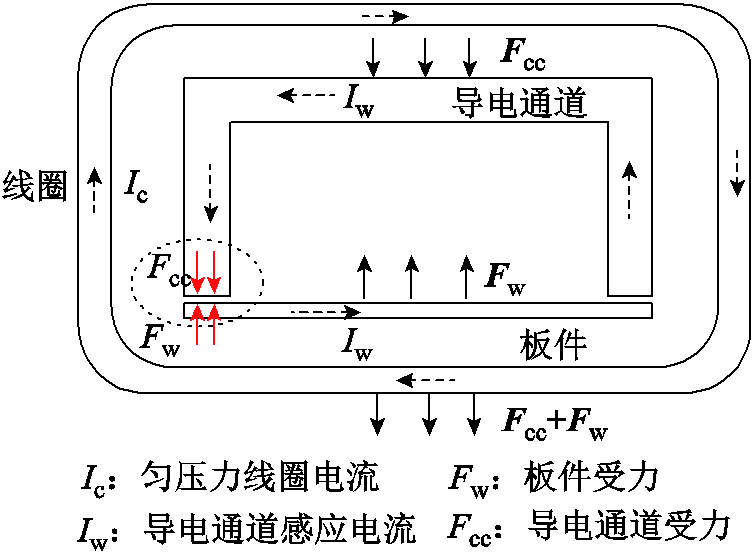

板件微成形制造一直是国内外电磁成形研究重点[78]。在传统机械力板件微成形中由于锋利尖锐的刀具接触工件表面,易带来损伤、增加接触面的表面粗糙度[79-81]、造成断裂[82]等影响。针对此类问题,Wu Zelin等[83]提出了一种内场匀压力线圈成形微型板件(双极板)的方案。匀压力线圈用于板件成形需要导电回路在外力作用下与板件形成闭合回路,而在板件成形时会产生使工件与板件分离的力(Fw与Fcc),因此很容易发生电弧烧蚀现象,且线圈在成形过程中也受到非常大的电磁力,易导致绝缘损坏。“内场”方案如图24所示,将导电通道与工件放置在螺旋线圈内部,在成形过程中通过在工件上产生送边力Fw,既能保证工件成形,又能改善原有方案中的电弧烧蚀现象,并且由线圈产生的电磁力Fcc能够辅助挤压导电通道与工件。该方案针对厚度为0.5 mm的钛板进行了成形实验,对比了不同放电能量下钛双极板的成形效果,如图25所示。观察板件中的成形棱边可知,当放电能量为4.8 kJ时,板件没有完全成形;而在7.5 kJ的放电能量下板件可正常成形。

图24 匀压力线圈成形板件示意图(内场)

Fig.24 Uniform pressure coil formed sheet (infield)

图25 双极板成形实验图(内场)[83]

Fig.25 Diagramof bipolar plate forming (infield)[83]

不同于前文所述电磁力组合式的电磁成形方案,使用两种或两种以上电磁力作用于成形区域,此方案在未加设线圈的情况下,通过将待成形工件置于线圈内部的方式,实现了电磁力的综合利用,即电磁力Fcc有助于导电通道与工件的接触,Fw在空腔区域用于工件成形,在接触区域又能改善导电通道和工件的连接性。

电磁力组合式电磁成形技术凸显了电磁力灵活可控的特点,但现有研究仅在轴-径向等方向上具有一定灵活性,并未从根本上直接改变力的方向,这也是电磁力虽灵活但并未完全发挥其在电磁成形中潜力的原因之一,如何最大限度地发挥电磁力灵活的特点,仍然是未来的研究重点。

目前,电磁成形技术虽优势明显,但纯电磁成形技术在实际制造中由于其局限性,限制了其适用范围:单纯电磁成形技术很难实现大尺寸钣金成形。大型工件成形需要配套的大型线圈、高电磁储能装置和高电压绝缘能力,这使得设备规模大,制造成本高。故许多专家学者提出了电磁成形工艺与焊接、机械制造等相结合的工艺组合式电磁成形技术。

传统冲压成形复杂结构(如T形三通结构)时,由于成形区域局部拉伸和弯曲变形较大,易出现起皱、破裂等缺陷,成形精度难以保证。电磁成形技术具有提高材料的成形极限[84]、成形力场可灵活调控和抑制金属起皱的特点[85]。V. J. Vohonut[86]率先提出了电磁辅助成形,将电磁成形技术与传统冲压相结合,将组合成形工艺应用于铝合金车门内板,初步验证了电磁辅助成形能够有效改善工件应变分布。Li Guangyao等[87]通过微观晶粒观察发现了准静态-动态拉伸的最终延伸率随着准静态预应变的增加而增加。Shang Jianhui等[88]在没有润滑的情况下对6111-T4铝合金进行电磁-冲压复合成形,板材的拉伸深度从44 mm提高到63.5 mm,有力地证明了组合工艺的优越性。J. Imbert等[89]针对铝合金V形弯曲件圆角,先通过传统冲压工艺成形出较大圆角半径20 mm,然后通过电磁成形获取小圆角半径5 mm,完成了工件拐角填充[90]。M. K. Choi等[91-92]将工艺组合成形应用于不同材料,对DP980/DP600成形并对成形线圈进行拓扑优化,获取了最佳的成形参数,证明了组合式成形工艺的可行性和普适性。G. S. Daehn等[93]在成形过程中交替进行冲压成形和电磁成形,板件的最大成形深度相对于传统冲压成形板件增加了44%,上述实验都表明了组合式工艺更能体现成形力场设计灵活的优点。

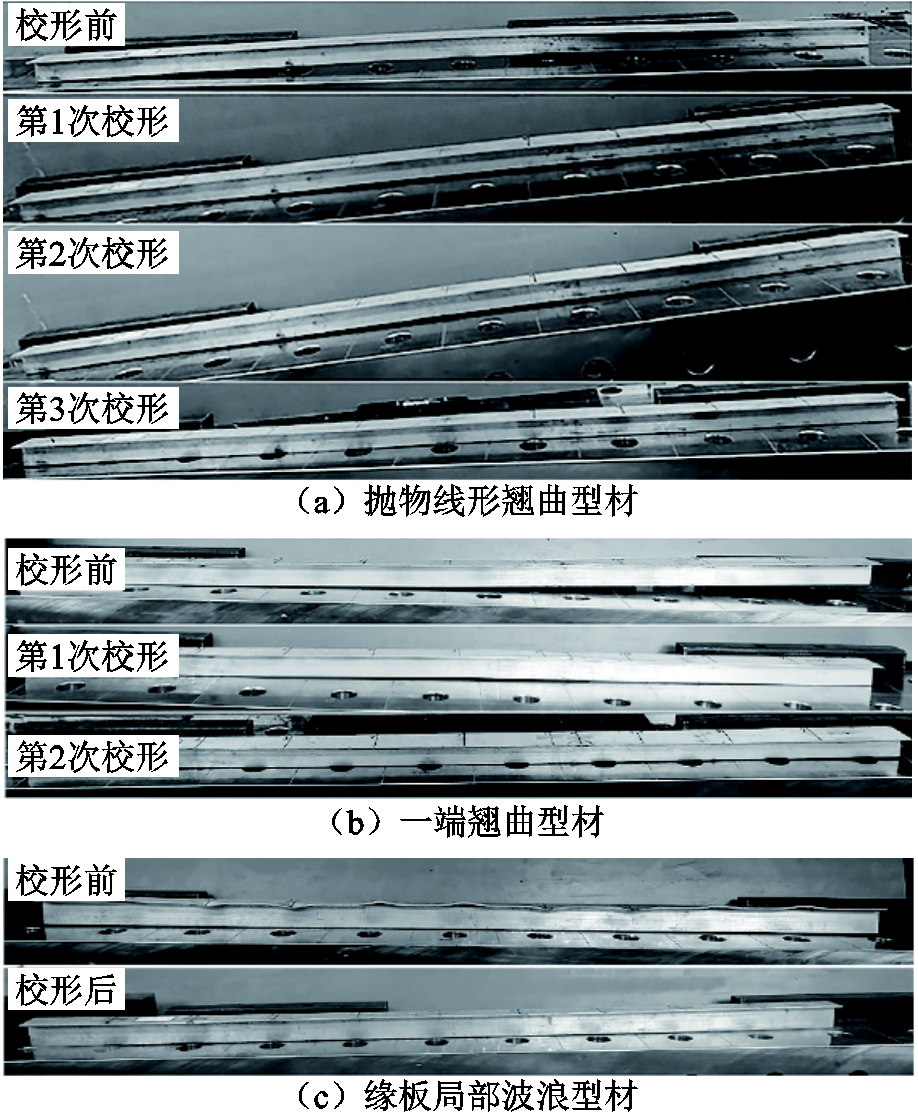

与传统冲压结合的电磁成形技术在提高工件成形极限的同时也可以抑制其弯曲、回弹[94]。镁/铝合金件为达所需强度,需对工件进行淬火处理,但淬火后的结构复杂、变形量大的型材极易发生形变[95-97],且应力分布不均匀,卸载后零件回弹严重。传统校形方法包括机械校形、热校形等[98],且均具有较为严苛的成形条件。由此,梅龙等[99]采用均匀压力线圈进行电磁校形,使曲面零件应力分布更均匀,通过电磁校形的零件在卸载后的轮廓非常接近目标零件轮廓。何逸汉等[100]对T形型材(火箭壳段上)淬火后存在整体曲翘和局部波浪的问题进行了电磁校形实验。驱动盘在电磁力的作用下向下运动,冲头和锤头随之下行打击工件,校形过程瞬间完成。装置结构如图26所示,实验针对长1 000 mm的2A12-T4铝合金T型材进行了高速冲击的电磁校形。图27a为抛物线形翘曲的三次电磁校形(打击中间部位)后的结果,电磁校形工艺以打击局部点的方式实现了整体校形。图27b为一端翘曲型材电磁校形,经过由左至右顺序打击校形,左端翘曲明显,校形完成。淬火后的局部波浪形翘曲如图27c所示,电磁校形方式需由左至右顺序打击集中在每段局部波浪处。结果表明,当型材厚度增加时,校形能量能够集中在局部波浪处,有利于提高校形效率。

图26 电磁校形实验装置结构[100]

Fig.26 Structure of the electromagnetic calibrator[100]

图27 电磁校形前后对比[100]

Fig.27 Before and after electromagnetic shaping[100]

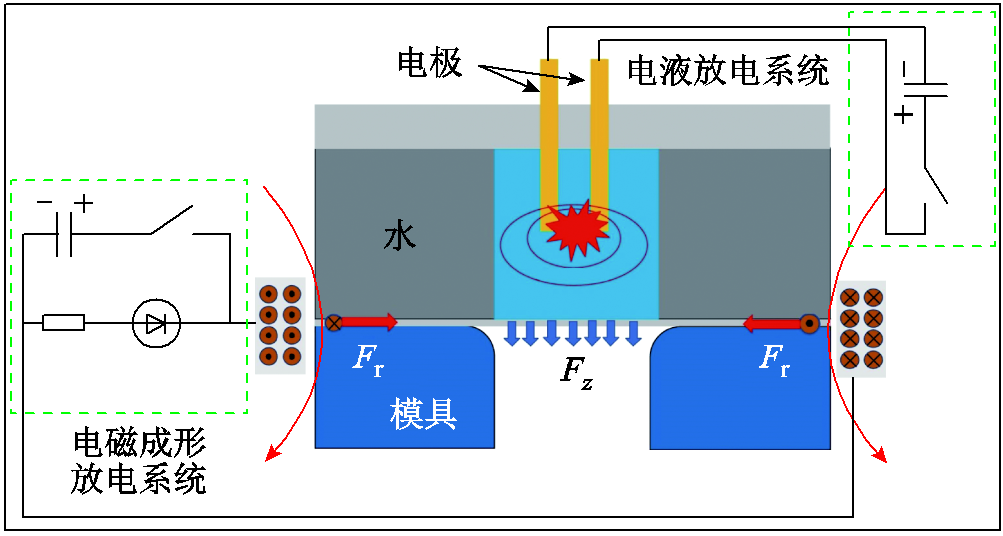

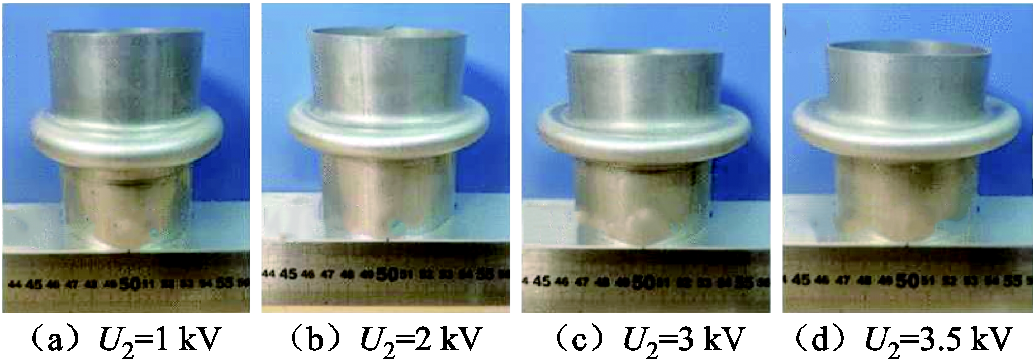

与EMF相似,电液成形(Electro-Hydraudic Forming, EHF)也是高能密、高应变速率成形,可以解决合金材料室温低塑形的问题。电液成形利用冲击波加载,在能量利用率上优势显著,但存在大型零件难加工、工件减薄严重以及成形设备复杂等缺陷[101]。为解决上述问题,Li Changxing等[102]提出将电磁成形与电液成形结合[102],成形原理如图28所示。针对铝合金板件,利用电磁成形技术以控制金属材料的动态流动,通过改变放电电压和放电时间使工件产生了不同的变形行为,实验证实了多脉冲组合工艺的有效性。进一步地,Wang Ziye等[103]基于人工神经网络遗传算法对电磁-电液组合成形工艺进行了多目标优化,通过精准的映射关系,获取了最佳的工艺参数组合,成形极限达到了56.52 mm,相比传统EHF提升了50.64%。Zhang Yi等[104]利用EHF工艺为管件胀形提供成形载荷,EMF工艺引入轴向电磁力以增强材料流动,使管件隆起深度增加了21.5%,管件壁厚减薄减少了44%,并发现了通过保持电液成形的放电电压U1=6 kV,调整电磁成形放电电压U2可以实现图29的各种成形形状,如C形、U形及Ω形。

图28 电磁-电液成形原理示意图[103]

Fig.28 Schematic diagram of the proposed process[103]

图29 不同放电电压下管件成形形状[104]

Fig.29 Forming shape of pipe fittings under different discharge voltages[104]

Wang Ziye等[105]还对电液-爆炸组合成形展开了研究,验证了组合高速脉冲成形的可行性。未来可将电磁成形、电液成形和爆炸成形这三种常见瞬间产生冲击力的塑形加工工艺进行组合,充分发挥三者的成形优势,或将产生出更加优越的组合式成形工艺。

铝件表面致密的氧化膜使得在传统工艺下焊接[106]成形困难,对于传统热焊接技术而言,高温下的金属化合物会严重影响接头的力学性能和抗腐蚀性。

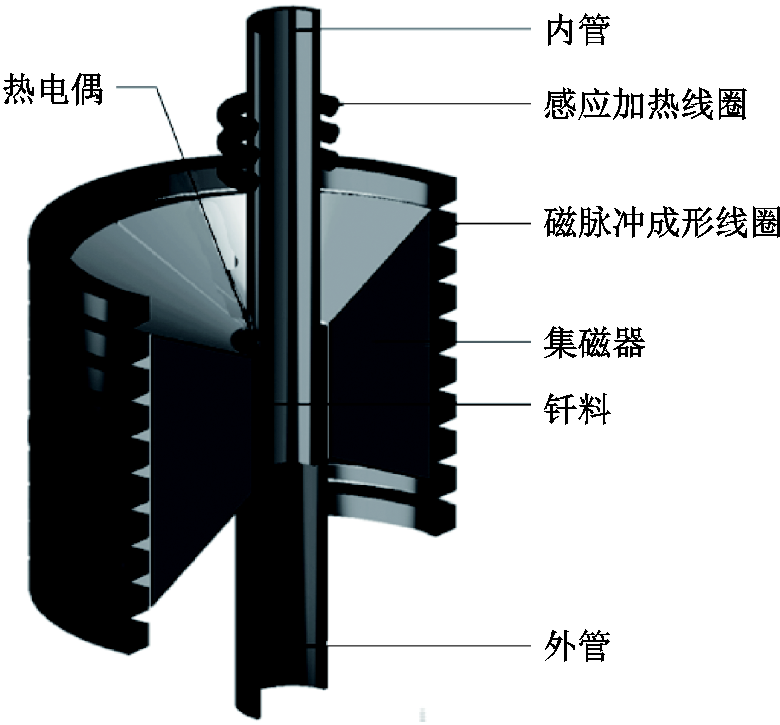

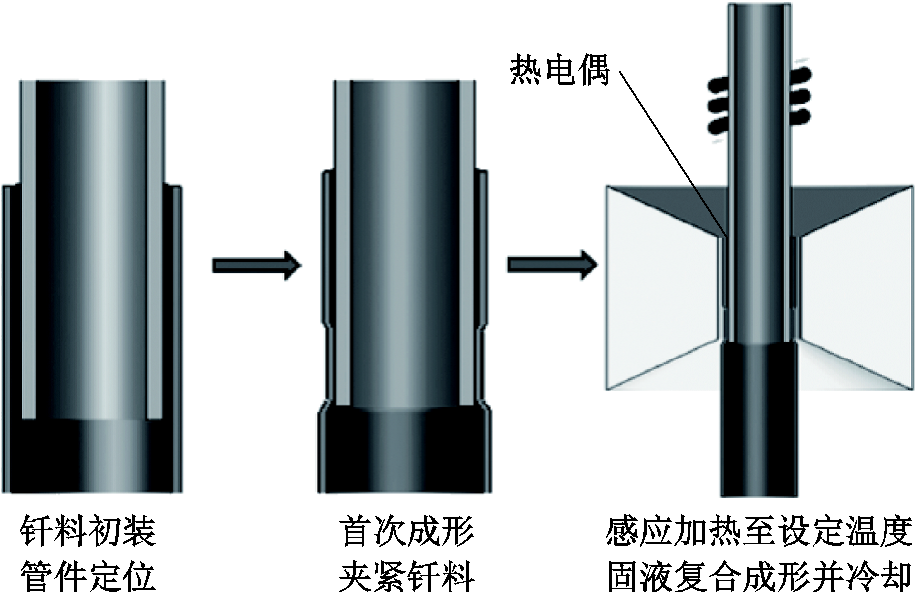

为此,黄尚宇等提出了一种磁脉冲-半固态复合辅助钎焊方案[107-108],如图30所示,方案结合了电磁成形、半固态成形和钎焊的复合优势。整个工序由两部分组成,如图31所示。首次放电利用电磁力使钎料中固相颗粒与铝管发生相互作用,进而去除其表面氧化膜,同时实现内外管件与钎料的装夹;随后感应加热并再次放电,实现管件钎料固液复合成形合并扩散连接。

图30 磁脉冲-半固态复合辅助钎焊工装示意图[108]

Fig.30 Schematicdiagram of the magnetic pulse-semi-solid composite assisted brazing tool[108]

图31 工艺过程

Fig.31 The processes

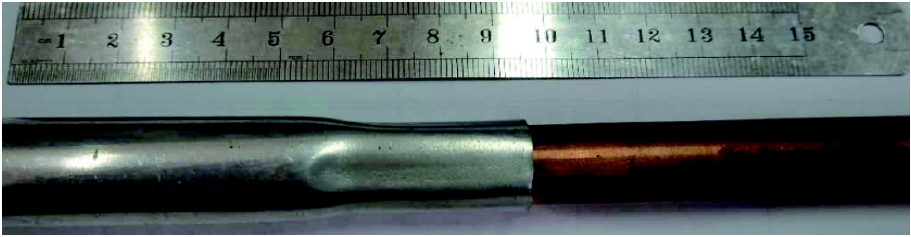

通过综合模拟及分析,针对外管径为21 mm的AA1060管件和内管径为17 mm的纯铜管件(间隙 1 mm、电容550 μF、电压8 kV)进行实验,实验结果如图32所示,在此电压下管件连接较为紧密,装夹后具有可靠的机械强度。

图32 实验结果[108]

Fig.32 Experimental results[108]

更进一步地,黄尚宇等[108-111]对复合辅助钎焊工艺的钎焊温度、二次放电电压、钎料厚度、钎料固相率、集磁器结构及钎缝凝固组织进行了研究。结果表明:温度条件影响钎料的固相率和铺展性,并决定了接头冶金连接状况不同[109], 当钎焊温度为410℃时,能够得到良好的钎焊接头组织且钎料晶粒圆整,尺寸细小[110];二次放电电压对于钎焊也有巨大的影响,黄海川等[111]通过研究发现,当二次放电电压为7 kV时,接头强度高于Al母材;钎料厚度也是影响钎焊工艺的原因之一,冯珂等[110]发现当半固态Zn-15Al-1.0Si钎料固相率为0.6、钎料厚度为300 μm时,能够获得以球晶组织为主的优质磁脉冲辅助半固态钎焊Cu/Al管接头,抗剪切强度达82.89 MPa;相较于等内径集磁器,带锥角集磁器能够有效改善Cu/Al接头的界面的连接质量,细化搭接区域中部纤缝组织,并提高钎焊接头的抗剪切强度[111]。

然而目前电磁辅助焊接多采用永磁体或者低频磁场[112],将高速率电磁脉冲与传统焊接技术结合的研究甚少,如何将二者的优势结合也将成为今后的热点研究。

总而言之,工艺组合式电磁成形技术充分体现了电磁成形技术的特点及电磁力应用的优势,成功地应用于不同成形形状的不同金属构件,与其他工艺相结合的现有研究方案更能体现出其高速率、成形力场可灵活调控等优势。

目前的研究成果已为电磁成形工艺的设计与应用带来了新颖的变化及灵感。在要求更高、更多元的制造业中,电磁成形技术已经从单一成形逐渐转变为组合式电磁成形技术,其成形方案及效果均有显著改善;与其他工艺相结合的方案更是起到事半功倍的效果。

如何更好地利用电磁力并进一步发挥电磁成形技术的优势,已成为现阶段研究的重点。在目前的研究基础上,后续可以从以下几点入手:

1)在驱动线圈组合方面侧重于如何获得更为通用的驱动线圈组合式电磁加载方案。电磁成形涉及多物理场耦合、放电电路参数、工件几何参数等,这些均会对成形效果产生影响。一种成形工件基本只能对应一种放电参数,如若工件或与线圈的相对位形发生变化,则又需要新的加载方案。因此,若能够获得具有普适性的驱动线圈组合式电磁加载方案,将进一步降低成本、节约资源,降低门槛。

2)在电磁力组合方面则着力于如何从电磁力的方向、类型以及用途方面充分发挥电磁力灵活可控的优点。电磁力作为非接触力优势明显,虽然电磁力大小方向灵活可控,但电磁力方向基本通过合力改变,现有方案并未完全发挥出其灵活可控的特点。

3)在工艺组合方面,结合两种甚至多种制造工艺的同时,能够发挥各种成形工艺的优势,在现有工艺的基础上,提高工艺组合式电磁成形的成熟度,充分发掘材料潜质,得到更为巧妙的工艺搭配组合,持续推进工件成形整体化、轻量化,亦将是今后的研究热点之一。

参考文献

[1] 熊奇, 唐红涛, 王沐雪, 等. 2011年以来电磁成形研究进展[J]. 高电压技术, 2019, 45(4): 1171-1181. Xiong Qi, Tang Hongtao, Wang Muxue, et al. Research progress of electromagnetic forming technique since 2011[J]. High Voltage Engineering, 2019, 45(4): 1171-1181.

[2] 邱立, 李彦涛, 苏攀, 等. 电磁成形中电磁技术问题研究进展[J]. 电工技术学报, 2019, 34(11): 2247-2259. Qiu Li, Li Yantao, Su Pan, et al. Research on electromagnetic problems in electromagnetic forming process[J]. Transactions of China Electrotechnical Society, 2019, 34(11): 2247-2259.

[3] 黎镇浩, 曹全梁, 赖智鹏, 等. 电流丝法在电磁成形线圈电流和工件电磁力计算中的应用[J]. 电工技术学报, 2018, 33(18): 4181-4190. Li Zhenhao, Cao Quanliang, Lai Zhipeng, et al. Application of current filament method on the calculation of current and force in electromagnetic forming[J]. Transactions on China Electrotechnical Society, 2018, 33(18): 4181-4190.

[4] 邱立, 余一杰, 聂小鹏, 等. 管件电磁胀形过程中的材料变形性能问题与电磁力加载方案[J]. 电工技术学报, 2019, 34(2): 212-218. Qiu Li, Yu Yijie, Nie Xiaopeng, et al. Study on material deformation performance and electromagnetic force loading in electromagnetic tube expansion process[J]. Transactions of China Electrotechnical Society, 2019, 34(2): 212-218.

[5] 李成祥, 石鑫, 周言, 等. 针对 H 型线圈的电磁脉冲焊接仿真及线圈截面结构影响分析[J]. 电工技术学报, 2021, 36(23): 4992-5001. Li Chengxiang, Shi Xin, Zhou Yan, et al. Electro- magnetic pulse welding simulation for H-type coil and analysis of the influence of coil cross-sectional structure[J]. Transactions of China Electrotechnical Society, 2021, 36(23): 4992-5001.

[6] 熊奇, 周丽君, 杨猛, 等. 单脉冲电磁成形中洛伦兹力在时间上的双向竞争关系及其对成形效果的影响[J]. 电工技术学报, 2022, 37(14): 3453-3463. Xiong Qi, Zhou Lijun, Yang Meng, et al. The two- way competitive relationship of Lorentz force in time in single pulse electromagnetic forming and its influence on forming effect[J]. Transactions of China Electrotechnical Society, 2022, 37(14): 3453-3463.

[7] 邱立, 杨新森, 常鹏, 等. 双线圈轴向压缩式管件电磁胀形电磁力分布规律与管件成形性能研究[J].电工技术学报, 2019, 34(14): 2855-2862. Qiu Li, Yang Xinsen, Chang Peng, et al. Electromagnetic force distribution and forming performance in electromagnetic tube expansion process with two coils[J]. Transactions of China Electrotechnical Society, 2019, 34(14): 2855-2862.

[8] Shisode M P, Hazrati J, Mishra T, et al. Modeling mixed lubrication friction for sheet metal forming applications[J]. Procedia Manufacturing, 2020, 47: 586-590.

[9] Sigvant M, Pilthammar J, Hol J, et al. Friction in sheet metal forming: influence of surface roughness and strain rate on sheet metal forming simulation results[J]. Procedia Manufacturing, 2019, 29: 512-519.

[10] 熊奇, 朱鑫辉, 赵翔, 等. AZ31镁合金管件电磁吸引式成形动态特性研究[J]. 电工技术学报, 2023, 38(10): 2577-2588, 2636. Xiong Qi, Zhu Xinhui, Zhao Xiang, et al. Research of dynamic characteristics in electromagnetic attraction forming of AZ31 magnesium alloy tube[J]. Transactions of China Electrotechnical Society, 2023, 38(10): 2577-2588, 2636.

[11] Yu Haiping, Li Chunfeng, Deng Jianghua. Sequential coupling simulation for electromagnetic–mechanical tube compression by finite element analysis[J]. Journal of Materials Processing Technology, 2009, 209(2): 707-713.

[12] Bach F, Bormann D, Walden L. Influence of forming rate on the microstructure and properties of materials subjected to electromagnetic forming asynopsis[C]// Proceedings of 3rd International Conference on High Speed Forming, Dortmund, Germany, 2008: 55-64.

[13] Psyk V, Risch D, Kinsey B L, et al. Electromagnetic forming—a review[J]. Journal of Materials Processing Technology, 2011, 211(5): 787-829.

[14] 李忠, 李春峰, 江宏伟, 等. 管坯电磁胀形的塑性动力分析[J]. 材料科学与工艺, 2004, 12(6): 637-641. Li Zhong, Li Chunfeng, Jiang Hongwei, et al. Dynamic plastic analysis of electromagnetic tube bulging[J]. Materials Science and Technology, 2004, 12(6): 637-641.

[15] Yu Haiping, Xu Zhidan, Fan Zhisong, et al. Mechanical property and microstructure of aluminum alloy-steel tubes joint by magnetic pulse welding[J]. Materials Science and Engineering: A, 2013, 561: 259-265.

[16] 李娜, 莫健华, 李奋强, 等. 铝合金板材电磁脉冲拉深实验与有限元模拟[J]. 锻压装备与制造技术, 2014, 49(4): 93-98. Li Na, Mo Jianhua, Li Fenqiang, et al. Experiment and finite element simulation of electromagnetic pulsed deep drawing process for aluminum alloy sheet[J]. China Metalforming Equipment & Manufacturing Technology, 2014, 49(4): 93-98.

[17] 陈石, 胡建华, 孙樊, 等. 铝合金曲面零件电磁校形试验研究[J]. 武汉理工大学学报, 2010, 32(19): 36-38, 101. Chen Shi, Hu Jianhua, Sun Fan, et al. Experimental research on electromagnetic bending and sizing of complex curved parts[J]. Journal of Wuhan University of Technology, 2010, 32(19): 36-38,101.

[18] 张骁. 脉冲强磁场作用下管件胀拉成形数值模拟与实验研究[D]. 武汉: 华中科技大学, 2017. Zhang Xiao. Numerical simulation and experimental study of tube bulging-drawing forming under pulsed high magnetic fields[D]. Wuhan: Huazhong University of Science and Technology, 2017.

[19] Xiong Qi, Huang Hao, Deng Changzheng, et al. A method to improve forming accuracy in electromagnetic forming of sheet metal[J]. International Journal of Applied Electromagnetics and Mechanics, 2018, 57(3): 367-375.

[20] Xiong Qi, Li Zhe, Tang Jianhua, et al. A flexible and economical method for electromagnetic flanging of tubes with field shapers[J]. The International Journal of Advanced Manufacturing Technology, 2021, 116(3): 1169-1177.

[21] Kamal M, Daehn G S. A uniform pressure electromagnetic actuator for forming flat sheets[J]. Journal of Manufacturing Science and Engineering, 2007, 129(2): 369-379.

[22] Lai Zhipeng, Han Xiaotao, Cao Quanliang, et al. The electromagnetic flanging of a large-scale sheet workpiece[J]. IEEE Transactions on Applied Superconductivity, 2014, 24(3): 1-5.

[23] Qiu Li, Yu Yijie, Xiong Qi, et al. Analysis of electromagnetic force and deformation behavior in electromagnetic tube expansion with concave coil based on finite element method[J]. IEEE Transactions on Applied Superconductivity, 2018, 28(3): 1-5.

[24] 邱立, 罗宝妮, 何琴, 等.基于凸型线圈双向电磁力加载的管件电磁翻边成形[J]. 热加工工艺, 2024(9): 152-158. Qiu Li, Luo Baoni, He Qin, etc. Electromagnetic flanging forming of pipe fittings based on bidirectional electromagnetic force loading of convex coils[J]. Hot working Process, 2024(9): 152-158.

[25] 李亮. 我国多时空脉冲强磁场成形制造基础研究进展[J]. 中国基础科学, 2016, 18(4): 25-35. Liang Li. Progress of the basic research on the space-time-controlled multi-stage pulsed magnetic field forming and manufacturing technology[J]. China Basic Science, 2016, 18(4): 25-35.

[26] 熊奇. 大尺寸铝合金板件电磁成形设计与实现[D]. 武汉: 华中科技大学, 2016. Xiong Qi. Design and realization of electromagnetic forming for large-scale aluminum alloy sheet[D]. Wuhan: Huazhong University of Science and Technology, 2016.

[27] 赖智鹏. 多时空脉冲强磁场金属板材电磁成形研究[D]. 武汉: 华中科技大学, 2017. Lai Zhipeng. Research on multi-space-time pulsed high magnetic field based electromagnetically sheet metal forming[D]. Wuhan: Huazhong University of Science and Technology, 2017.

[28] 刘宁. 基于可控电磁力加载的大尺寸铝合金壳体件电磁整体成形技术研究[D]. 武汉: 华中科技大学, 2020. Liu Ning. Research on electromagnetic integral forming technology of large-scale aluminum alloy shell parts under controllable electromagnetic force[D]. Wuhan: Huazhong University of Science and Technology, 2020.

[29] Cao Quanliang, Lai Zhipeng, Xiong Qi, et al. Electromagnetic attractive forming of sheet metals by means of a dual-frequency discharge current: design and implementation[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1): 309-316.

[30] Li Meng, Lai Zhipeng, Xu Wei, et al. A versatile electromagnetic actuator for sheet and tube flanging: process principle, simulation, and experimental validation[J]. Journal of Manufacturing Processes, 2022, 81: 311-327.

[31] Zhang Zixuan, Lai Zhipeng, Li Changxing, et al. Production and use of adaptive pulsed Lorentz force for multi-step electromagnetic sheet metal forming: method, experimental validation, and application[J]. The International Journal of Advanced Manufacturing Technology, 2022, 120(7/8): 5521-5536.

[32] Lai Zhipeng, Cao Quanliang, Han Xiaotao, et al. Design, implementation, and testing of a pulsed electromagnetic blank holder system[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(4): 1-5.

[33] Cao Quanliang, Han Xiaotao, Lai Zhipeng, et al. Analysis and reduction of coil temperature rise in electromagnetic forming[J]. Journal of Materials Processing Technology, 2015, 225: 185-194.

[34] Du Limeng, Xia Liangyu, Li Xian, et al. Adjustable Current waveform via altering the damping coefficient: a new way to reduce Joule heating in electromagnetic forming coils[J]. Journal of Materials Processing Technology, 2021, 293: 117086.

[35] 王紫叶, 杨猛, 熊奇. 电磁成形过程中线圈温升及结构优化[J]. 电工技术学报, 2021, 36(18): 3891-3901. Wang Ziye, Yang Meng, Xiong Qi. Coil temperature rise and structure optimization in electromagnetic forming[J]. Transactions of China Electrotechnical Society, 2021, 36(18): 3891-3901.

[36] Deng Jianghua, Li Chunfeng, Zhao Zhiheng, et al. Numerical simulation of magnetic flux and force in electromagnetic forming with attractive force[J]. Journal of Materials Processing Technology, 2007, 184(1/2/3): 190-194.

[37] Cao Quanliang, Lai Zhipeng, Xiong Qi, et al. Electromagnetic attractive forming of sheet metals by means of a dual-frequency discharge current: design and implementation[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1): 309-316.

[38] Xiong Qi, Tang Hongtao, Wang Muxue, et al. Design and implementation of tube bulging by an attractive electromagnetic force[J]. Journal of Materials Processing Technology, 2019, 273: 116240.

[39] Xiong Qi, Tang Hongtao, Deng Changzhen, et al. Electromagnetic attraction-based bulge forming in small tubes: fundamentals and simulations[J]. IEEE Transactions on Applied Superconductivity, 2018, 28(3): 1-5.

[40] Xiong Qi, Gao Dun, Li Zhe, et al. Electromagnetic attraction bulging of small aluminum alloy tube based on a field shaper[J].The International Journal of Advanced Manufacturing Technology, 2021, 117(1/2): 511-521.

[41] 熊奇, 李青山, 李哲, 等. 集磁器对电磁成形驱动线圈发热影响及机理[J]. 电工技术学报, 2023, 38(2) :285-296. Xiong Qi, Li Qingshan, Li Zhe, et al. Influence and mechanism of field shaper on heating of electromagnetic forming drive coil[J]. Transactions of China Electrotechnical Society, 2023, 38(2): 285-296.

[42] Ouyang Shaowei, Wang Chen, Li Changxing, et al. Improving the uniformity and controllability of tube deformation via a three-coil forming system[J]. The International Journal of Advanced Manufacturing Technology, 2021, 114(5): 1533-1544.

[43] Ouyang Shaowei, Xu Xiaofei, Li Xiaoxiang, et al. Systematic investigation of deformation behavior of tubes in a three-coil electromagnetic forming process[J].The International Journal of Advanced Manufacturing Technology, 2022, 119(7/8): 5163-5174.

[44] Qiu Li, Li Yantao, Yu Yijie, et al. Electromagnetic force distribution and deformation homogeneity of electromagnetic tube expansion with a new concave coil structure[J]. IEEE Access, 2019, 7: 117107-117114.

[45] Qiu Li, Yu Yijie, Yang Yuqi, et al. Analysis of electromagnetic force and experiments in electromagnetic forming with local loading[J]. International Journal of Applied Electromagnetics and Mechanics, 2018, 57(1): 29-37.

[46] Cui Xiaohui, Mo Jianhua, Li Jianjun, et al. Produce a large aluminium alloy sheet metal using electromagnetic-incremental (EM-IF) forming method: experiment and numerical simulation[C]//5th International Conference on High Speed Forming, Dortmund, Germany, 2012: 59-70.

[47] Cui Xiaohui, Mo J H, Li J J, et al. Electromagnetic incremental forming (EMIF): a novel aluminum alloy sheet and tube forming technology[J]. Journal of Materials Processing Technology, 2014, 214(2): 409-427.

[48] Cui Xiaohui, Li Jianjun, Mo Jianhua, et al. Investigation of large sheet deformation process in electromagnetic incremental forming[J]. Materials & Design, 2015, 76: 86-96.

[49] Yu Haiping, Jin Yanye, Hu Lan, et al. Two-step method to improve geometry accuracy of elongated hole flanging by electromagnetic forming[J].The International Journal of Advanced Manufacturing Technology, 2020, 106(7/8): 3117-3129.

[50] Su Hongliang, Huang Liang, Li Jianjun, et al. Two-step electromagnetic forming: a new forming approach to local features of large-size sheet metal parts[J]. International Journal of Machine Tools and Manufacture, 2018, 124: 99-116.

[51] Zhang Qixian, Huang Liang, Li Jianjun, et al. Investigation of dynamic deformation behaviour of large-size sheet metal parts under local Lorentz force[J]. Journal of Materials Processing Technology, 2019, 265: 20-33.

[52] Su Hongliang, Huang Liang, Li Jianjun, et al. On the forming uniformity during a single layer forming of electromagnetic incremental forming[J].The International Journal of Advanced Manufacturing Technology, 2020, 107(11/12): 4561-4572.

[53] Li Hongwei, Yao Xuan, Yan Siliang, et al. Analysis of forming defects in electromagnetic incremental forming of a large-size thin-walled ellipsoid surface part of aluminum alloy[J]. Journal of Materials Processing Technology, 2018, 255: 703-715.

[54] Liu Xianlong, Huang Liang, Li Jianjun, et al. An electromagnetic incremental forming (EMIF) strategy for large-scale parts of aluminum alloy based on dual coil[J]. The International Journal of Advanced Manufacturing Technology, 2019, 104(1/2/3/4): 411-431.

[55] Li Xiaoxiang, Cao Quanliang, Lai Zhipeng, et al. Bulging behavior of metallic tubes during the electromagnetic forming process in the presence of a background magnetic field[J]. Journal of Materials Processing Technology, 2020, 276: 116411.

[56] Zhang Wang, Ouyang Shaowei, Du Limeng, et al. Electromagnetic forming with automatic feedback control of Lorentz force distribution: a new forming method and its application to high-uniformity tube deformation[J]. Journal of Materials Processing Technology, 2023, 313: 117869.

[57] 欧阳少威. 双级线圈下管件电磁吸引力成形行为研究[D]. 武汉: 华中科技大学, 2019.Ouyang Shaowei. The research of tube electromagnetic attractive forming behavior based on a dual-coil system[D]. Wuhan: Huazhong University of Science and Technology, 2019.

[58] 熊奇, 杨猛, 周丽君, 等. 双线圈吸引式板件电磁成形过程中的涡流竞争问题[J]. 电工技术学报, 2021, 36(10): 2007-201. Xiong Qi, Yang Meng, Zhou Lijun, et al. Eddy currents competition in electromagnetic forming process of plates by double-coil attraction[J]. Transactions of China Electrotechnical Society, 2021, 36(10): 2007-2017.

[59] 黄攀, 黄亮, 苏红亮, 等. 基于板料电磁翻边的电磁力分布对成形质量影响的数值模拟研究[J]. 稀有金属材料与工程, 2019, 48(9): 2987-2993. Huang Pan, Huang Liang, Su Hongliang, et al. Electromagnetic force distribution and its effect on the forming quality for numerical simulation study of electromagnetic flanging of sheet metal[J]. Rare Metal Materials and Engineering, 2019, 48(9): 2987-2993.

[60] 刘欣, 杨景超, 李恒, 等. 管路构件塑性变形连接技术研究进展及挑战[J]. 航空学报, 2022, 43(4): 172-192. Liu Xin, Yang Jingchao, Li Heng, et al. Critical review on tube joining by plastic deformation[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(4):172-192.

[61] 张文忠, 陈浩, 董占国, 等. 基于磁脉冲技术的铝合金板材圆孔翻边工艺研究[J]. 航天制造技术, 2009(4): 5-7, 16. Zhang Wenzhong, Chen Hao, Dong Zhanguo, et al. Research on formability of aluminum alloy flanged hole by EMF[J]. Aerospace Manufacturing Technology, 2009(4): 5-7, 16.

[62] Yu Haiping, Zheng Qiuli, Wang Shoulong, et al. The deformation mechanism of circular hole flanging by magnetic pulse forming[J]. Journal of Materials Processing Technology, 2018, 257: 54-64.

[63] 王煜, 张松, 龚雄, 等. 电磁脉冲成形技术在铝合金壁板翻边孔上的应用与研究[J]. 制造业自动化, 2021, 43(1)1-3,11. Wang Yu, Zhang Song, Gong Xiong, et al. Application and research of electromagnetic pulse forming used on flanging hole of aluminum alloy panels[J]. Manufacturing Automation, 2021, 43(1):1-3,

[64] 谢冰鑫, 黄亮, 黄攀, 等. 铝合金板料电磁翻边全流程工艺研究[J]. 中国机械工程, 2021, 32(2): 220-226 Xie Bingxin, Huang Liang, Huang Pan, et al. Research on whole process route of electromagnetic flanging of aluminum alloy sheets[J]. China Mechanical Engineering, 2021, 32(2): 220-226

[65] Xiong Qi, Huang Hao, Xia Liangyu, et al. A research based on advance dual-coil electromagnetic forming method on flanging of small-size tubes[J].The International Journal of Advanced Manufacturing Technology, 2019, 102(9/10/11/12): 4087-4094.

[66] 周中玉. 基于双级线圈径向驱动的孔电磁强化方法研究[D]. 武汉: 华中科技大学, 2014. Zhou Zhongyu. Research of hole electromagnetic strengthening method based on two-stage coils and radially driven[D]. Wuhan: Huazhong University of Science and Technology, 2014.

[67] Qiu Li, Yu Yijie, Wang Ziwei, et al. Analysis of electromagnetic force and deformation behavior in electromagnetic forming with different coil systems[J]. International Journal of Applied Electromagnetics and Mechanics, 2018, 57(3): 337-345.

[68] 张望, 王于東, 李彦涛, 等. 基于双向电磁力加载的管件电磁翻边理论与实验[J]. 电工技术学报, 2021, 36(14) : 2904-2911. Zhang Wang, Wang Yudong, Li Yantao, et al. Theory and experiment of tube electromagnetic flanging based on bidirectional electromagnetic force loading[J]. Transactions of China Electrotechnical Society, 2021, 36(14): 2904-2911.

[69] 李盛飞, 朱险峰, 刘子伟, 等. 带集磁器的吸引式电磁力小管件翻边方法[J]. 强激光与粒子束, 2023, 35(5): 220281. Li Shengfei, Zhu Xianfeng, Liu Ziwei, et al. Attractive electromagnetic force flanging method for small tube fittings with magnetic field shaper[J]. High Power Laser and Particle Beams, 2023, 35(5): 220281.

[70] Xiong Qi, Zhao Xiang, Zhou Hang, et al. A triple-coil electromagnetic two-step forming method for tube fitting[J]. The International Journal of Advanced Manufacturing Technology, 2021, 116(11): 3905-3915.

[71] Obermeyer E J, Majlessi S A. A review of recent advances in the application of blank-holder force towards improving the forming limits of sheet metal parts[J]. Journal of Materials Processing Technology, 1998, 75(1/2/3): 222-234.

[72] Lai Zhipeng, Cao Quanliang, Han Xiaotao, et al. Design, implementation, and testing of a pulsed electromagnetic blank holder system[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(4): 1-5.

[73] Huang Yujie, Han Xiaotao, Cao Quanliang, et al. Design and analysis of a pulsed electromagnetic blankholder system for electromagnetic forming[J]. Procedia Engineering, 2017, 207: 347-352.

[74] Lai Zhipeng, Cao Quanliang, Zhang Bo, et al. Radial Lorentz force augmented deep drawing for large drawing ratio using a novel dual-coil electromagnetic forming system[J]. Journal of Materials Processing Technology, 2015, 222: 13-20.

[75] Lai Zhipeng, Cao Quanliang, Han Xiaotao, et al. Investigation on plastic deformation behavior of sheet workpiece during radial Lorentz force augmented deep drawing process[J]. Journal of Materials Processing Technology, 2017, 245: 193-206.

[76] Chen Meng, Lai Zhipeng, Cao Quanliang, et al. Investigation on deformation control of sheet metal in radial Lorentz force augmented deep drawing[J].The International Journal of Advanced Manufacturing Technology, 2019, 105(5/6): 2369-2381.

[77] Chen Meng, Lai Zhipeng, Cao Quanliang, et al. Improvement on formability and forming accuracy in electromagnetic forming of deep-cavity sheet metal part using a dual-coil system[J]. Journal of Manufacturing Processes, 2020, 57: 209-221.

[78] Kamal M, Daehn G S. A uniform pressure electromagnetic actuator for forming flat sheets[J]. Journal of Manufacturing Science and Engineering, 2007, 129(2): 369-379.

[79] Fu M W, Chan W L. A review on the state-of-the-art microforming technologies[J]. The International Journal of Advanced Manufacturing Technology, 2013, 67(9): 2411-2437.

[80] 李研彪, 陈强, 张利. 钛合金薄壁曲面液态金属-磨粒流加工仿真与试验研究[J]. 机械工程学报, 2021, 57(23): 220-231. Li Yanbiao, Chen Qiang, Zhang Li. Titanium alloy Thin-walled curved surface liquid metal-abrasive flow machining simulation and experimental research[J].Journal of Mechanical Engineering, 2021, 57(23): 220-231.

[81] Ran J Q, Fu M W, Chan W L. The influence of size effect on the ductile fracture in micro-scaled plastic deformation[J]. International Journal of Plasticity, 2013, 41: 65-81.

[82] 何志鹏, 赵虎. 微型断路器电寿命评估[J]. 电工技术学报, 2022, 37(4): 1031-1040. He Zhipeng, Zhao Hu. Electrical lifespan evaluation of miniature circuit breakers[J]. Transactions of China Electrotechnical Society, 2022, 37(4): 1031-1040.

[83] Wu Zelin, Cao Quanliang, Fu Junyu, et al. An inner-field uniform pressure actuator with high performance and its application to titanium bipolar plate forming[J]. International Journal of Machine Tools and Manufacture, 2020, 155: 103570.

[84] 周言, 李成祥, 杜建, 等. 放电电压对镁-铝磁脉冲焊接中金属射流及结合界面的影响[J]. 电工技术学报, 2022, 37(2): 459-468, 495. Zhou Yan, Li Chengxiang, Du Jian, et al. Investigation on the effect of discharge voltage on metal jet and bonded interface in Mg-Al magnetic pulse welding[J]. Transactions of China Electrotechnical Society, 2022, 37(2): 459-468, 495.

[85] 周纹霆, 董守龙, 王晓雨, 等. 电磁脉冲焊接电缆接头的装置的研制及测试[J]. 电工技术学报, 2019, 34(11): 2424-2434. Zhou Wenting, Dong Shoulong, Wang Xiaoyu, et al. Development and test of magnetic pulse welding cable joint device[J]. Transactions of China Electro- technical Society, 2019, 34(11): 2424-2434.

[86] Vohnout V J. A hybrid quasi-static/dynamic process for forming large sheet metal parts from alumi-num alloys[D]. Columbus: Ohio State University, 1998.

[87] Li Guangyao, Deng Huakun, Mao Yunfei, et al. Study on AA5182 aluminum sheet formability using combined quasi-static-dynamic tensile processes[J]. Journal of Materials Processing Technology, 2018, 255: 373-386.

[88] Shang Jianhui, Daehn G. Electromagnetically assisted sheet metal stamping[J]. Journal of Materials Processing Technology, 2011, 211(5): 868-874.

[89] Imbert J, Worswick M. Electromagnetic reduction of a pre-formed radius on AA 5754 sheet[J]. Journal of Materials Processing Technology, 2011, 211(5): 896-908.

[90] Imbert J, Worswick M. Reduction of a pre-formed radius in aluminium sheet using electromagnetic and conventional forming[J]. Journal of Materials Processing Technology, 2012, 212(9): 1963-1972.

[91] Choi M K, Huh H, Park N. Process design of combined deep drawing and electromagnetic sharp edge forming of DP980 steel sheet[J]. Journal of Materials Processing Technology, 2017, 244: 331-343.

[92] Iriondo E, Alcaraz J L, Daehn G S, et al. Shape calibration of high strength metal sheets by electromagnetic forming[J]. Journal of Manufacturing Processes, 2013, 15(2): 183-193.

[93] Daehn G S, Vivek A, Shang Jianhui. Electromagnetically assisted sheet metal stamping and deep drawing[M]// Tekkaya A E, Homberg W, Brosius A. 60 Excellent Inventions in Metal Forming. Berlin. Heidelberg: Springer Vieweg, 2015: 107-112.

[94] 高嵩, 于长春, 梁继才, 等. 铝型材多点三维拉压复合弯曲成形工艺[J]. 机械工程学报, 2019, 55(20): 152-159. Gao Song, Yu Changchun, Liang Jicai, et al. Multi-points 3D stretch-press bending technology for aluminum profile[J]. Journal of Mechanical Engineering, 2019, 55(20): 152-159.

[95] 刘素贞, 田钰霖, 张闯, 等. 铝合金拉伸塑性变形的非线性电磁超声检测[J]. 电工技术学报, 2020, 35(15): 3153-3160. Liu Suzhen, Tian Yulin, Zhang Chuang, et al. Nonlinear electromagnetic acoustic detection of aluminum alloys with tensile plastic deformation[J]. Transactions of China Electrotechnical Society, 2020, 35(15): 3153-3160.

[96] Rotpai U, Arlai T, Nusen S, et al. Novel flow stress prediction and work hardening behavior of aluminium alloy AA7075 at room and elevated temperatures[J]. Journal of Alloys and Compounds, 2022, 891: 162013.

[97] 解社娟, 吴磊, 仝宗飞, 等. 塑性变形和疲劳对304不锈钢电磁属性的影响研究及微观结构分析(英文) [J]. 电工技术学报, 2018, 33(14): 3170-3176. Xie Shejuan, Wu Lei, Tong Zongfei, et al. Investigation of electromagnetic properties of 304 austenitic stainless steel with plastic deformation and fatigue damage and microstructure analysis[J]. Transactions of China Electrotechnical Society, 2018, 33(14): 3170-3176.

[98] 詹梅, 王隽文, 樊晓光, 等. 薄壁构件淬火变形调控研究进展[J]. 锻压技术, 2018, 43(7): 62-70. Zhan Mei, Wang Junwen, Fan Xiaoguang, et al. Research progress on quenching distortion control for thin-walled components[J]. Forging & Stamping Technology, 2018, 43(7): 62-70.

[99] 梅龙, 刘维, 邹希凡, 等. 采用均匀压力线圈的铝合金曲面零件电磁校形[J]. 锻压技术, 2020, 45(9): 118-122. Mei Long, Liu Wei, Zou Xifan, et al. Electromagnetic sizing for aluminium alloy curved surface part by uniform pressure coils[J]. Forging & Stamping Technology, 2020, 45(9): 118-122.

[100] 何逸汉, 于海平, 邓将华, 等. 铝合金T形型材电磁校形试验研究[J]. 塑性工程学报, 2020, 27(7): 86-93. He Yihan, Yu Haiping, Deng Jianghua, et al. Experimental study on electromagnetic shape correction of aluminum alloy with T-profile[J]. Journal of Plasticity Engineering, 2020, 27(7): 86-93.

[101] 毛云飞. AA5052铝合金高速下本构及断裂模型研究[D]. 长沙: 湖南大学, 2019. Mao Yunfei. Research on constitutive model and ductile fracture criterion of AA5052 at high work piece speed[D]. Changsha: Hunan University, 2019.

[102] Li Changxing, Lai Zhipeng, Wang Chen, et al. Toward better metal flow control in electrohydraulic sheet forming by combining with electromagnetic approach[J]. Journal of Materials Processing Technology, 2022, 299: 117343.

[103] Wang Ziye, Lai Zhipeng, Li Changxing, et al. Data-driven method for process optimization in electromagnetic-electrohydraulic hybrid high-velocity sheet metal forming[J].The International Journal of Advanced Manufacturing Technology, 2022, 121(7/8): 4355-4365.

[104] Zhang Yi, Li Xiaoxiang, Tang Yinghao, et al. Research into controlling the material flow for electrohydraulic forming alloy tubes by a pulsed magnet[J]. IEEE Transactions on Applied Super-conductivity, 2022, 32(6): 1-5.

[105] Wang Ziye, Lai Zhipeng, Han Xiaotao, et al. Antisymmetric deformation behavior during eccentric explosion electro-hydraulic sheet forming process[J]. Materials and Manufacturing Processes, 2023, 38(6): 692-700.

[106] 李成祥, 杜建, 周言, 等. 电磁脉冲板件焊接设备研制及镁/铝合金板焊接实验研究[J]. 电工技术学报, 2021, 36(10): 2018-2027. Li Chengxiang, Du Jian, Zhou Yan, et al. Development of electromagnetic pulse welding equipment for plates and experimental research on magnesium/aluminum alloy welding[J]. Transactions of China Electrotechnical Society, 2021, 36(10): 2018-2027.

[107] 黄海川. 铜铝管磁脉冲—半固态复合辅助钎焊工艺过程模拟及实验研究[D]. 武汉: 武汉理工大学, 2019. Huang Haichuan. Simulation and experimental research on the process of magnetic pulse-semisolid hybrid assisted brazing of Cu/Al tubes[D]. Wuhan: Wuhan University of Technology, 2019.

[108] 王振东, 黄尚宇, 李佳琪, 等. Zn-Al钎料固相率及组分对Cu/Al管磁脉冲-半固态复合辅助钎焊接头质量的影响初探[J]. 材料科学与工艺, 2020, 28(4): 1-7. Wang Zhendong, Huang Shangyu, Li Jiaqi, et al. Preliminary study on the influence of solder solid phase rate and composition of Zn-Al filler metal on the quality of magnetic pulse-semisolid hybrid assisted soldering of Cu/Al tubes[J]. Materials Science and Technology, 2020, 28(4): 1-7.

[109] 高远, 黄尚宇, 邓凌波, 等. 温度条件对铜管/铝磁脉冲-半固态复合辅助钎焊接头微观组织的影响[J]. 锻压技术, 2019, 44(10): 169-175. Gao Yuan, Huang Shangyu, Deng Lingbo, et al. Influence of temperature condition on microstructure of Cu tube/Al tube brazed joint produced by magnetic pulse and semi-solid composite auxiliary technology[J].Forging & Stamping Technology, 2019, 44(10): 169-175.

[110] 冯珂, 黄尚宇, 邓凌波, 等. Zn-Al-Si钎料厚度对磁脉冲辅助半固态钎焊Cu/Al管接头组织性能的影响[J]. 材料科学与工艺, 2021, 29(5): 39-47. Feng Ke, Huang Shangyu, Deng Lingbo, et al. Effect of Zn-Al-Si filler metal thickness on microstructure and properties of Cu/Al tube joints by magnetic pulse assisted semi-solid brazing[J]. Materials Science and Technology, 2021, 29(5): 39-47.

[111] 黄海川, 黄尚宇, 李清宁, 等. 放电电压对Cu/Al管磁脉冲-半固态复合辅助钎焊质量的影响[J]. 塑性工程学报, 2020, 27(2): 60-67. Huang Haichuan, Huang Shangyu, Li Qingning, et al. Effect of discharge voltage on quality of Cu/Al tube magnetic pulse-semisolid hybrid assisted brazing[J]. Journal of Plasticity Engineering, 2020, 27(2): 60-67.

[112] Farhang B, Tanrikulu A A, Ganesh-Ram A, et al. Electromagnetic field-assisted laser welding of NiTi to stainless steel: towards a lightweight, high-strength joint with preserved properties[J]. Journal of Materials Processing Technology, 2023, 314: 117888.

Abstract Electromagnetic forming (EMF) is a special forming method with high energy and high speed for metal materials by using pulsed electromagnetic force. Unlike traditional mechanical stamping, EMF is not limited by force transfer medium properties and is simple in device design. The application had significant limitations because the early electromagnetic forming scheme essentially realized the repulsive force forming effect of the workpiece, and the repulsive force was primarily dominated by the electromagnetic force analysis. With its many benefits, combined electromagnetic forming technology is currently gaining traction in the media. In order to achieve more flexible, accurate, and efficient forming, the combined electromagnetic forming technology combines drive-coils, force fields, and forming processes to diversify the magnetic field configuration and forming force field.

Based on the EMF principles and electromagnetic force control methods, the latest research results are divided into three parts according to the different application levels: drive-coil combined type, electromagnetic force combined type and forming process combined type. This review focuses on the implementation concepts, technological solutions and application implications of the three types.

The first part is the drive-coil combined type. Due to the limited strength of a single coil and the poor uniformity of the electromagnetic force generated during the forming process, another option is a more flexible combined drive-coil method. Multiple drive-coils provide the electromagnetic force required for forming and improving the magnetic force distribution. The drive-coil combined electromagnetic forming is presented separately from the combined coil repulsive forming and attractive forming. The drive-coil combined electromagnetic forming method skillfully neutralizes the harsh requirements on the coil.

The second part is electromagnetic force combined type.The application of electromagnetic force in traditional electromagnetic forming is all in a single direction, a single attraction or repulsion force, and the combined effect of electromagnetic force has not broken through. In practical applications, the electromagnetic force can be used for both single-directional and multi-directional loading and forming; it can be used as a forming force as well as an auxiliary force (blank holding force, transmission force); and the attractive electromagnetic force can be combined with the repulsive electromagnetic force.

The third part is forming process combined type. Pure electromagnetic forming technology's range of applications is restricted by its limitations in real-world manufacturing. Many experts and scholars have proposed a process that combines electromagnetic forming technology with welding and mechanical manufacturing. A new type of combined forming scheme combined with traditional stamping, electro-hydraulic forming, and welding is introduced respectively.

Lastly, research hotspots on the EMF are predicted and the technology's future is explored. At present, there are still many unsolved problems in the existing electromagnetic forming technology. How to obtain a universal drive-coil forming scheme, how to make use of the flexible point of the electromagnetic force, and how to combine two or even multiple manufacturing processes to fully utilize variousforming process advantages are meaningful. This will provide important reference and guidance for further in-depth research of the EMF and will accelerate its promotion and application in key application fields such as lightweight integration of aerospace and automotive.

Keywords:Electromagnetic forming, pulsed magnetic field, drive coil, electromagnetic force, forming process

DOI: 10.19595/j.cnki.1000-6753.tces.230348

中图分类号:TM154

武汉强磁场学科交叉基金资助项目(WHMFC202121)。

收稿日期 2023-03-23

改稿日期 2023-05-25

熊 奇 男,1990年生,博士,副教授,博士生导师,研究方向为电磁成形、多场耦合分析及储能技术。E-mail:pandaqi0218@gmail.com

周丽君 女,1997年生,硕士研究生,研究方向为电磁场分析及应用。E-mail:754914487@qq.com(通信作者)

(编辑 郭丽军)