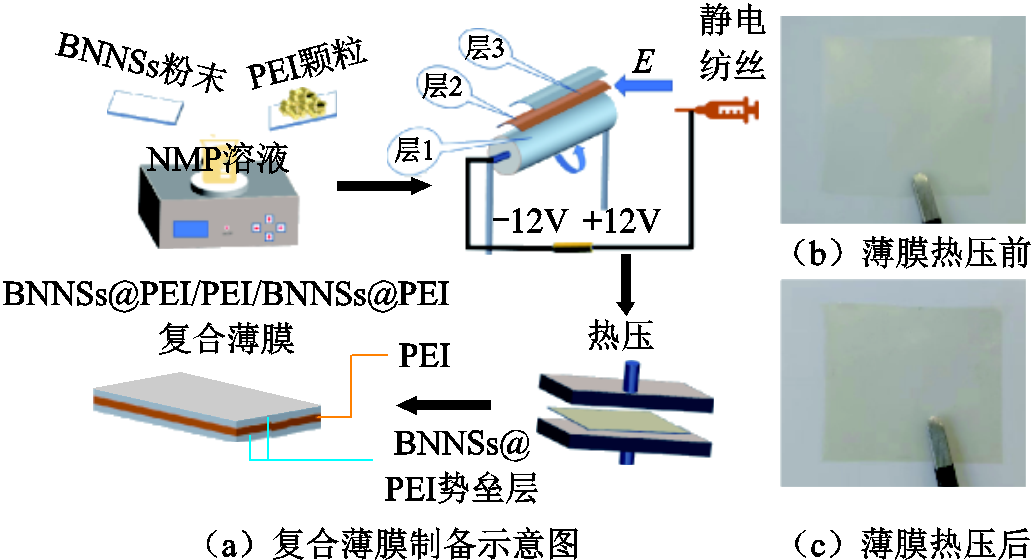

图1 复合薄膜的制备过程

Fig.1 Process of composite film preparation

摘要 聚合物基高温储能介质因其较高的功率密度及优异的充放电效率被广泛应用在电气和电子等领域。该文选用不同粒径的氮化硼纳米片(BNNSs)作为填料,掺杂到聚醚酰亚胺(PEI)中构建势垒层,添加在纯PEI两侧制备拥有三明治结构的复合薄膜,探究粒径大小在不同温度/填充体积分数下对复合薄膜的介电性能及储能性能的影响。研究发现,构建BNNSs势垒层的三明治结构复合薄膜显著抑制了介质的高温电导,提高了充放电效率,且较小粒径BNNSs填充势垒层能更有效地提高击穿场强和储能密度,其中掺杂200 nm粒径BNNSs体积分数为5%的复合薄膜在常温下的储能密度可达5.65 J/cm3,充放电效率高达96%,即使在150℃下,储能密度和充放电效率也可分别达到2.52 J/cm3和95%。通过随机击穿模型阐明了粒径大小及三明治势垒层结构对击穿性能的提升机制。该文提出的含有势垒层的三明治复合结构为高温下复合薄膜储能特性优化提供了新的策略。

关键词:电介质薄膜 聚醚酰亚胺 氮化硼 介电性能 储能密度

电能在当今社会中扮演着不可或缺的角色,其存储与转换可以更加高效地利用资源,这对于推动低碳经济方面起着重要作用,而新能源的大规模应用也意味着电力电子器件需要适应更多的工作场合和极端环境[1-4]。电容器是电子设备、新能源发电等多个领域的核心器件,其中聚合物薄膜电容器因具有充放电速率快和易加工等其他类型电容器无法比拟的优势,逐渐成为研究热点之一[5]。此外,航空航天领域和新能源汽车逆变器等复杂工作环境的应用需求也对新型聚合物介质的高温储能性能提出了更加严格的要求[6-8]。例如,应用在电磁炮等脉冲装置中的复合薄膜,一般要求常温下储能密度大于 8 J/cm3,充放电效率大于等于95%,现有聚合物很难突破瓶颈;在新能源汽车逆变器中,常用的双向拉伸聚丙烯薄膜(Biaxially Oriented Polypropylene, BOPP),其储能密度仅为1~2 J/cm3,最高使用温度仅到105℃,已经无法满足未来新能源汽车逆变器用聚合物薄膜的发展要求[9-13]。

应用在高温领域的储能介质,例如聚碳酸酯(Polycarbonate, PC,玻璃化转变温度Tg≈150℃)、聚醚酰亚胺(Polyetherimide, PEI,Tg≈217℃)、聚萘二甲酸乙二醇酯(Polyethylene Naphthalate, PEN,Tg>160℃)、芴聚酯(Fluorene Polyester,FPE,Tg≈330℃)等,尽管拥有较高的温度耐受性和击穿场强,但较低的介电常数却限制了其储能密度。研究人员后期发现,通过引入高介电常数的填料可以提高复合薄膜的总体介电常数[14],但单纯追求高介电常数会在造成介质局部电场畸变的同时增加介质损耗,不易获得理想的高温储能性能[15-16]。另一种方法是通过添加宽带隙填料在提高击穿场强的同时利用基体-填料间界面极化优化介质整体介电性能[17-18]。

近年来六方氮化硼(h-BN)因其稳定的化学性能,良好的热导率和宽带隙(约为6 eV)受到广泛关注,以其优越的高势垒特点和导热性在绝缘介质领域被用作各种填料和涂层,单层或掺杂h-BN的多层结构被大量采用[19-23]。Liu Guang等制备了具有电纺氮化硼层的三明治结构聚合物作为高温储能电介质,在PC薄膜的两侧设计并涂覆具有不同厚度的h-BN层,在热传导和载流子阻挡方面发挥了作用。层厚为1 μm的BN-1在100℃、500 kV/mm电场下的储能密度为5.52 J/cm3,比纯PC高出15.10%[24]。Li Meng等利用氮化硼纳米片(Boron Nitride Nano-Sheets, BNNSs)的高绝缘性能构建具有高势垒层的复合材料,使BNNSs/聚二甲基硅氧烷(Polydimethylsiloxane, PDMS)复合薄膜的体积电阻率和击穿强度达到7.5×1013 Ω·cm和39.8 kV/mm[25]。尽管h-BN性能优异,但目前仍然存在一些问题,例如多层结构中的含量和尺寸对介质高温下性能的影响尚不明晰。除了填料的化学性质存在区别外,同一种填料的物理状态也会对薄膜的介电性能有着很大影响。Xue Pengjie等探究了SiO2填料的多晶型和粒径对SiO2-聚醚醚酮(Polyetheretherketone, PEEK)复合材料介电性能、机械性能和热性能的影响,结果显示通过颗粒填充优化可以使得复合材料的机械强度显著提高,同时介电性能和热性能保持良好[26]。以上研究表明,在相同的基体情况下,纳米填料的形状、大小、维度(零维、一维、二维),以及分布状态会对介质的介电性能产生影响[27-29]。

由于BNNSs势垒层能够增加电极与基体之间的整体带隙宽度,减小载流子注入的数量和概率,且在高温条件下,由于BNNSs本身较高的热导率,能够快速散热降低热击穿发生的概率;此外,为了降低有机物与无机物间界面兼容性差等影响,本文将BNNSs作为填料掺杂聚合物中构建势垒层以提高介质-电极势垒高度。同时无机填料的引入势必会导致复合薄膜内部产生电场畸变,因此在纯聚合物两侧构建势垒层以减小电场畸变概率。本文选取PEI作为基体,在基体两侧掺杂不同粒径的BNNSs构筑势垒层,研究不同粒径的BNNSs构筑三明治势垒层结构对介电性能及储能特性的影响[30-31]。测试结果表明,复合薄膜显示出良好储能性能的同时也具备优异的高温耐受性,本工作可对后续高温下介质薄膜的结构设计提供指导。

实验中使用的材料为:聚醚酰亚胺(PolyK技术有限公司)、h-BN(北京伊诺凯科技有限公司)、粒径约为2 μm的BNNSs(Sigma Aldrich)、N-甲基吡咯烷酮溶液(N-Methylpyrrolidone, NMP,国药集团化学试剂)、N,N-二甲基甲酰胺(N,N-Dimethylformamide, DMF,国药集团化学试剂)。

首先称取适量的h-BN粉末加入DMF溶液中,搅拌6 h至完全溶解后超声48 h。取上清液以8 000 r/min离心0.5 h,结束后收集沉淀置于60℃下真空烘干,研磨后获得200 nm粒径的BNNSs。2 μm粒径的BNNSs购自Sigma Aldrich公司。

复合薄膜的制备过程如图1所示。称取适量的PEI颗粒和NMP溶液加入烧杯中,50℃搅拌12 h至PEI颗粒在NMP溶液中分散均匀。按照不同体积分数,分别取对应含量BNNSs粉末加入PEI溶液中,再将混合溶液搅拌3 h后超声分散0.5 h得到相应的混合溶液。最后将混合溶液抽真空,形成纺丝前驱体。利用静电纺丝技术分别制备纯PEI薄膜和BNNSs@PEI薄膜,针头处施加+12 V电压,高速定向机处施加-12 V电压,针头推进速度为3 mm/min,纺丝后得到的湿膜在60℃下干燥12 h后取出。图1b为纺丝后烘干的复合薄膜,表面呈现白色雾状。随后热压退火得到厚度约为14~19 μm的薄膜,如图1c所示。

图1 复合薄膜的制备过程

Fig.1 Process of composite film preparation

X射线物相表征采用荷兰帕纳科公司生产的EMPYREAN锐影X射线衍射仪(X-Ray Diffractometer, XRD),测试电压为40 kV、测试电流为40 mA、扫描范围为2θ=10°~90°、步长为0.2°、每步时间为2 s。复合薄膜横截面表征采用日本日立公司生产的SU8020扫描电子显微镜(Scanning Electron Microscope, SEM)。复合薄膜分子结构分析采用德国EQUINOX55型傅里叶变换红外(Fourier Transform Infrared, FTIR)光谱仪,实验测试范围600~1 800 cm-1。采用Alpha-A宽频介电谱分析仪,测试频率范围为100~107 Hz,电极为直径为9 mm的铝电极。铁电性能综合测量仪由美国Radiant Premier Ⅱ公司生产,测量单边电滞回线和双边电流密度曲线,外加电压波形是频率为100 Hz的单边三角形,电极为直径为3 mm的铝电极,击穿测试升压速率为300 V/s,储能测试每轮升压20 V/μm。

为了研究BNNSs尺寸大小对聚合物基复合薄膜内部击穿路径演化的影响,利用随机击穿模型对两种不同粒径BNNSs填充的PEI基复合薄膜的击穿路径演化进行了模拟[32]。在该模型中,复合薄膜各点的击穿概率P(r)为

(1)

(1)

式中,E(r)为由外加电场和聚合物基复合薄膜微观结构所决定的局部电场强度;Eb(r)为聚合物基复合薄膜的固有击穿强度;分母中的总和是局部电场强度超过击穿强度所有点的总和。将所有已击穿点的最近邻点排列起来随机,随机的概率与最近邻点电场强度的二次方成正比。利用谱迭代摄动法求解静电平衡方程,得到局域电场分布[33]。

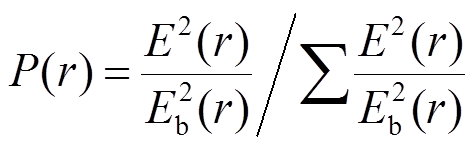

为了表征不同粒径下复合薄膜的晶相结构,利用X射线衍射仪(XRD)对介质薄膜进行了物相分析,结果如图2所示。在图2中可以看出,复合薄膜在2θ=26.7°处有一个特征衍射峰,对应BNNSs的(002)晶面,表明BNNSs的存在[9]。所有测试曲线均在2θ约为20°附近有一个漫散射峰,对应PEI的非晶衍射特征峰[34]。随着BNNSs体积分数的增加,由于BNNSs的散射作用可能影响到PEI的散射,导致PEI衍射峰强度出现下降。图2中不存在其他杂峰,表明复合薄膜中并未存在其他的物质。

图2 XRD图像

Fig.2 XRD diagram

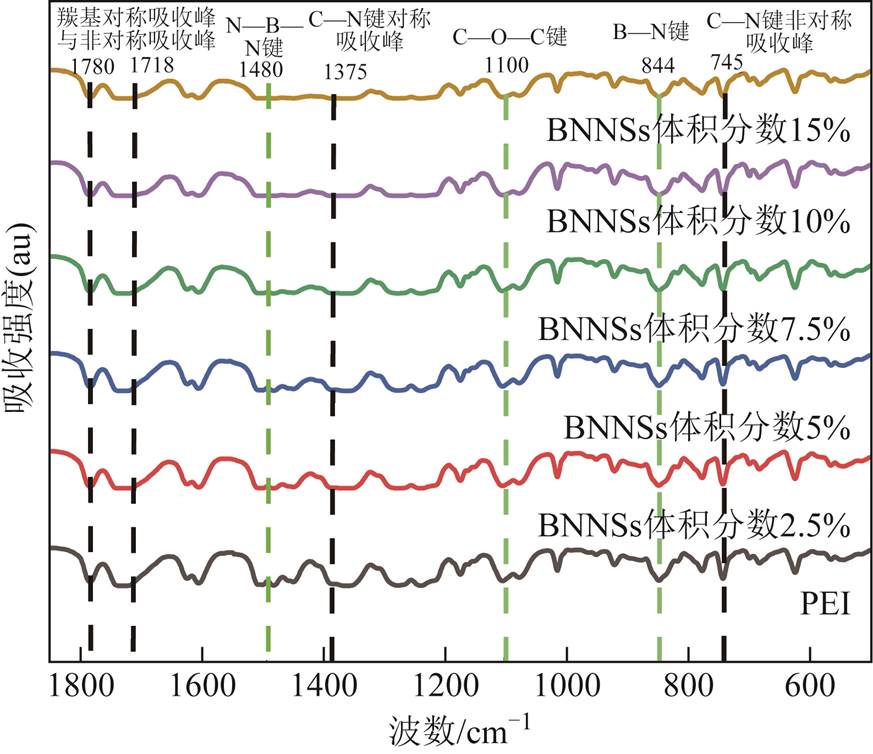

为了表征复合介质薄膜的分子结构,得到FTIR图像如图3所示。1 780 cm-1和1 718 cm-1处对应PEI酰亚胺基团中的羰基对称伸缩振动吸收峰和非对称振动吸收峰,1 375 cm-1和745cm-1处分别对应C—N键的伸缩振动吸收峰和弯曲振动吸收峰,1 100 cm-1处对应C—O—C键的吸收峰[31],而1 480 cm-1和844 cm-1处分别对应BNNSs的N—B—N键弯曲振动吸收峰和B—N键的伸缩振动吸收峰[35-36]。

图3 FTIR图像

Fig.3 FTIR diagram

为了观察填充不同粒径BNNSs填料后其在复合薄膜内部的分布状态,通过SEM观察液氮脆断后复合薄膜的断面形貌,并测得了对应的元素映射光谱,如图4所示。在图4a和图4b中可以看出,所有三明治结构复合薄膜中位于中心层的纯PEI层厚度约为14 μm,两侧势垒层厚度约为2 μm,层间界面处整齐致密,未见明显片状结构,且不存在孔洞杂质等缺陷。另外,如图4c和图4d所示,EDS(energy dispersive spectrometer)能谱图表明在PEI层两侧存在大量B元素和N元素聚集,这表明BNNSs@PEI复合薄膜层致密均匀,BNNSs大部分呈平行面内分布,三明治结构薄膜结构制备成功。

图4 复合薄膜横截面SEM图像和EDS能谱图

Fig.4 SEM images of cross section of composite films and EDS energy spectrums of composite films

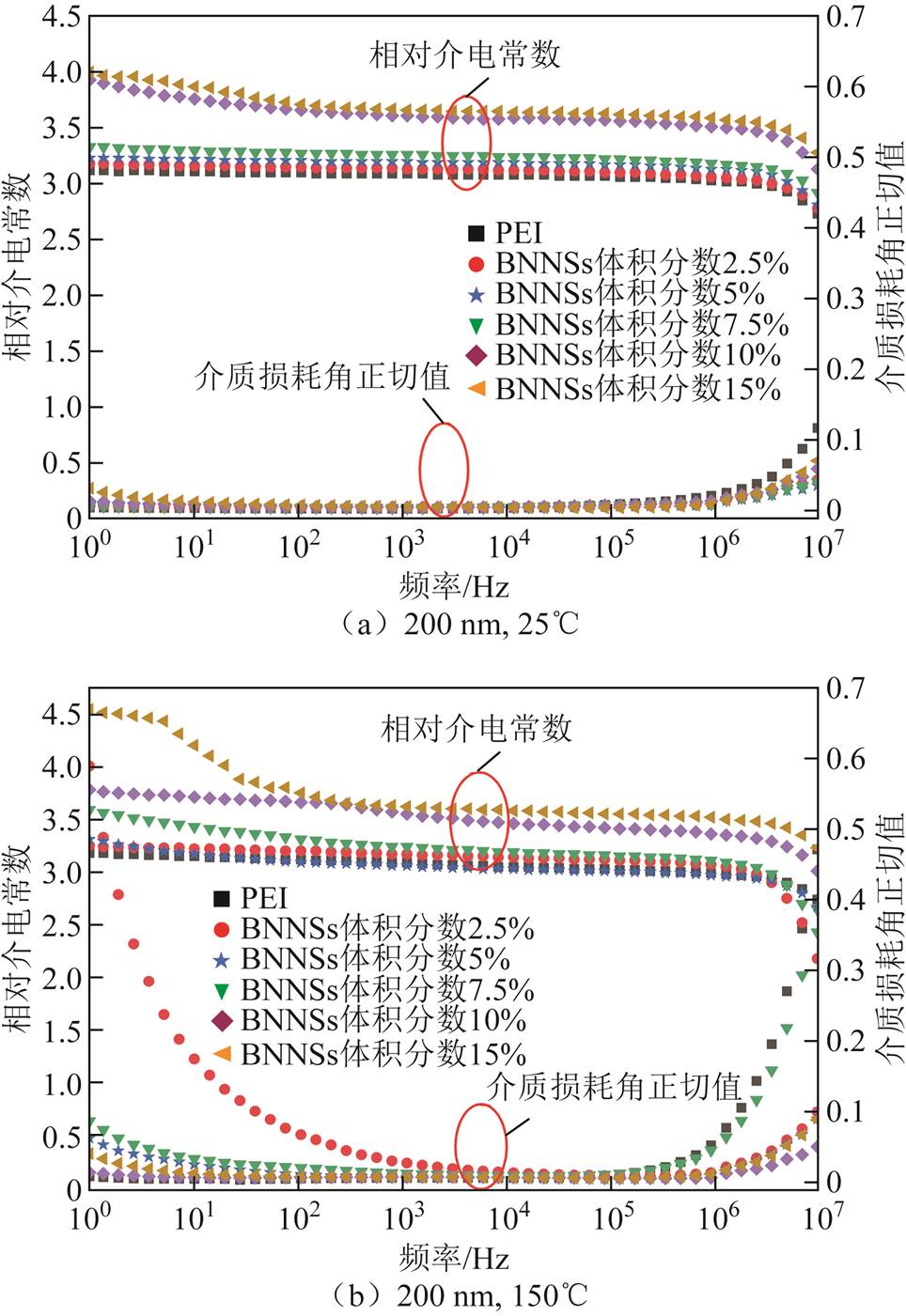

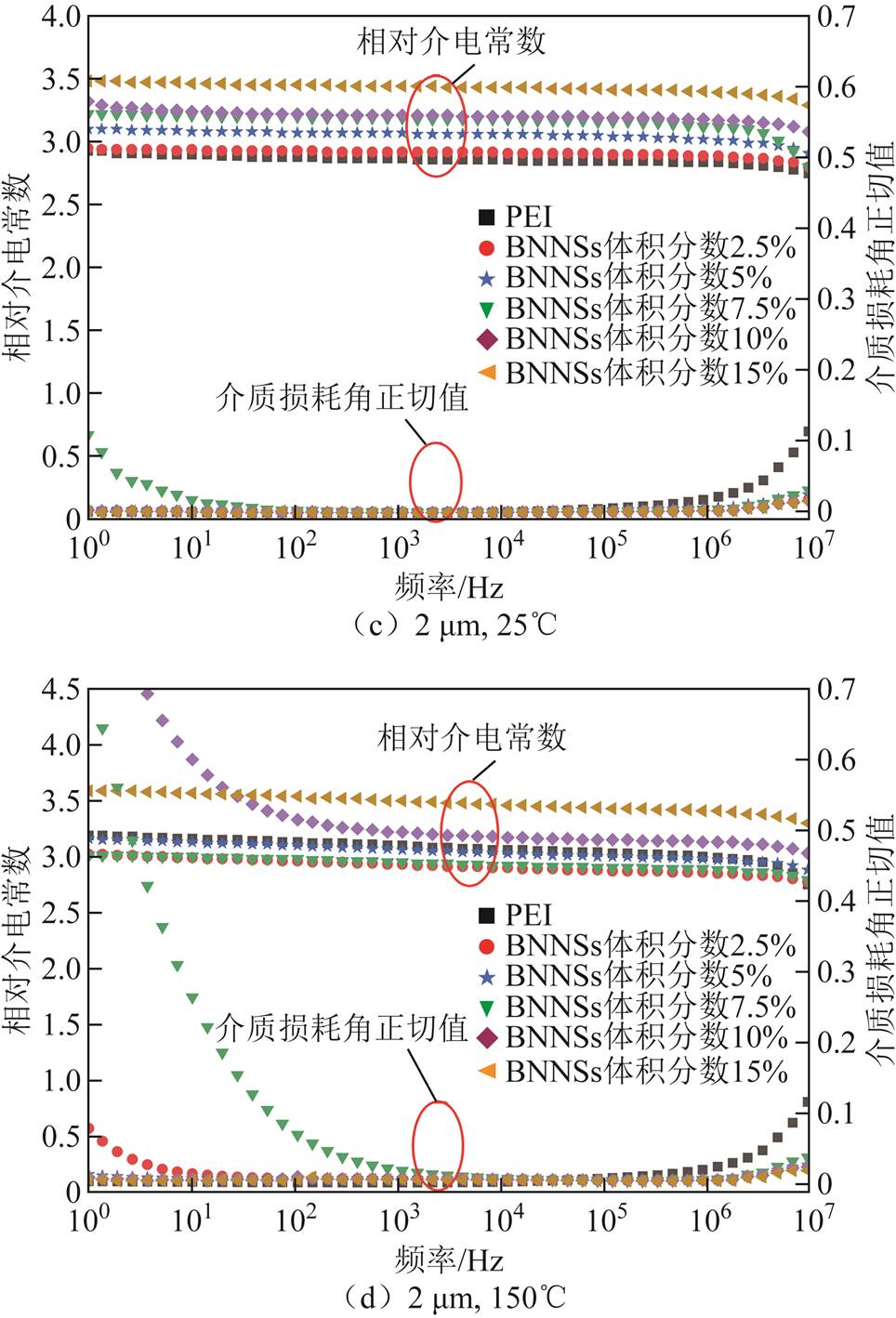

对填充了不同粒径BNNSs的三层复合薄膜进行了不同温度下的介电性能测试,结果如图5所示。随着测试频率升高,在高频下相对介电常数出现下降,这归因于在低频电场下偶极子转向极化可以跟上电场变化速度而获得充分极化,当频率逐渐升高,偶极子的转向逐渐无法跟上电场频率变化,造成极化程度下降,进而导致介电常数降低[37-38]。在相同温度下,随着两种粒径BNNSs掺杂含量的提高,复合薄膜的介电常数也对应提升,这是因为BNNSs含量的增加使单位体积内界面数量增加,进而增强了界面极化[39]。而在相同体积分数下,随着温度提高,介电常数有少量上升,这是由于分子热运动有利于转向极化的建立[40]。此外,小粒径填充的薄膜介电常数在相同体积分数和温度下大于大粒径填充的薄膜。这是因为在同样体积分数下,复合薄膜内小粒径填料的数量更多,界面极化更强烈[41-42]。另外观察到在150℃的低频段下,个别高体积分数的薄膜样品介电常数出现上升,这可能是因为在样品制备过程中引入的空间电荷没有及时释放,在低频介电测试中出现了与其他掺杂含量明显不同的变化。

图5 复合薄膜介电性能

Fig.5 Dielectric property of composite film

从图5中可以看到,在相同温度下,随着BNNSs体积分数的增加,介质损耗呈现先增加再降低的趋势。首次增加可能是因为BNNSs的加入导致有机-无机界面的出现,两者相容性较差使得界面损耗增加,另外,体积分数的升高可能导致局部BNNSs发生团聚现象,使电场畸变程度增加[43-44]。随后体积分数的升高导致介质损耗下降可能是因为大量小型团聚形成一个整体势垒层,反而改善了部分局部电场的畸变,造成损耗的降低。而在相同体积分数下,随着温度的升高,介质损耗也有略微增加,这是由于温度升高导致分子热运动加剧造成损耗值增加。值得注意的是,在相同条件下小粒径填料的损耗要大于大粒径,这同样可以归因于小粒径体系中界面更多,分子间摩擦更强烈。复合介质的介质损耗角正切值在低频下极化不稳定,但在高频下的损耗均低于PEI介质。

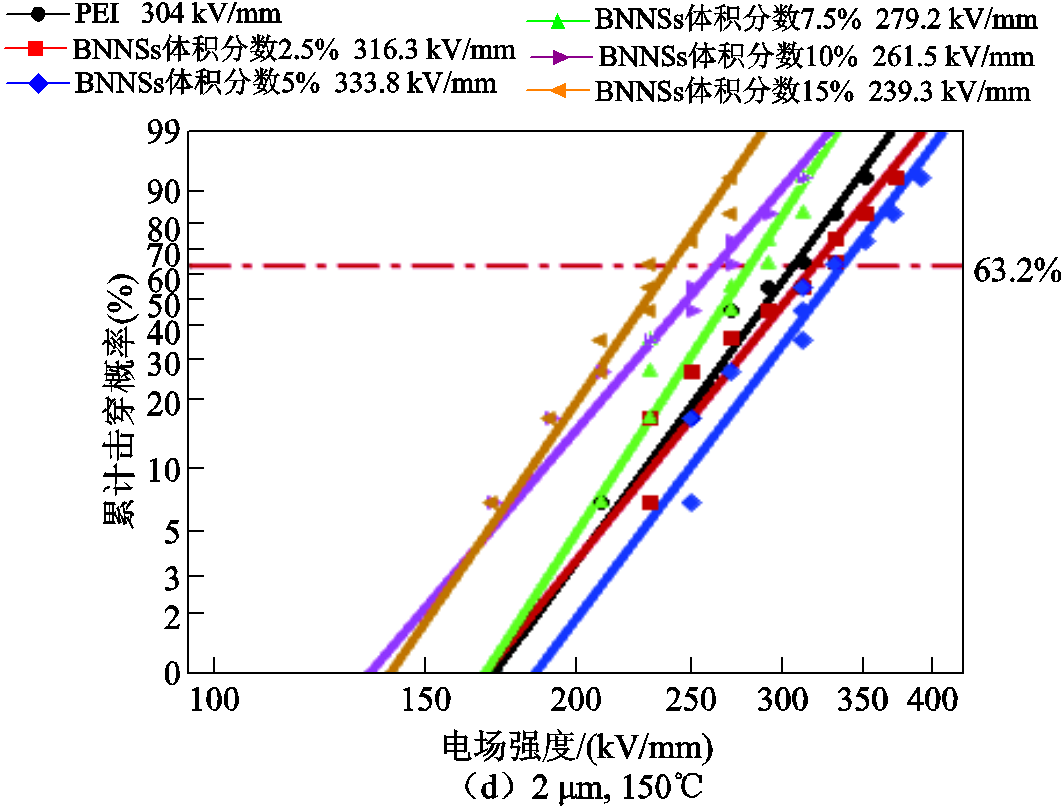

击穿场强Eb是决定介质薄膜绝缘性能的重要参数,常温和高温下不同粒径和不同体积分数的介质薄膜击穿性能威布尔分布如图6所示。图6中显示,在相同温度下两种粒径复合薄膜的Eb随着掺杂体积分数的提高表现出先增加后降低的趋势,均在BNNSs体积分数为5%时拥有了最大的Eb。而在150℃的高温下,复合介质薄膜击穿场强随着体积分数变化也拥有相同的变化趋势,但击穿场强数值有所下降。造成这种现象的原因可能是:宽禁带BNNSs的加入能够在介质和电极界面上形成高势垒层,抑制载流子注入的同时还具备良好的导热性,有助于肖特基发射的产生,抑制高温下的热击穿[45-46]。另外,BNNSs的引入有助于使复合薄膜内部的电场分布更加合理,能承受更大的外界电压。而当BNNSs的填充量进一步增加时会造成局部团聚,从而导致电场畸变和缺陷增加,使载流子更容易在介质中传递,最终导致薄膜发生击穿[40]。

图6 复合薄膜击穿性能的威布尔分布

Fig.6 Weibull diagram of composite film

在相同体积分数下,温度越高复合薄膜击穿性能下降越严重,这是由于在高温下分子内载流子热运动加剧,部分电子能够被激发越过禁带进入到上方的导带中成为自由电子,而温度越高,电子获得的活化能越大,介质被击穿所需要的电场强度越低。此外,在低掺杂条件下(体积分数为5%),小粒径的BNNSs表现出最高的击穿性能,在常温下,Eb达到了584.4 kV/mm,而在150℃的高温下依旧保持了361.6 kV/mm的击穿场强,表现出比大粒径更好的高温耐受性。这主要归因于合成工艺中静电纺丝法使二维BNNSs在喷涂过程中受电场力的作用倾向于平行复合薄膜的方向,即垂直于电场,从而限制了电荷的迁移。而且小粒径的BNNSs相比于大粒径能够显著增加介质薄膜内部界面的数量,增加载流子散射[47-48]。在相同体积分数下,复合薄膜结构中小粒径填料的数量多于大粒径,因此小粒径填料颗粒之间的间距小于大粒径,这有利于抑制击穿路径的发展。另外实验数据中发现在25℃下体积分数为10%与15%时的小粒径样品的击穿强度低于大粒径的样品,这是由于相同体积分数下小粒径的BNNSs数量要远多于大粒径BNNSs,会形成局部团聚现象导致击穿性能劣化[28,49-51]。

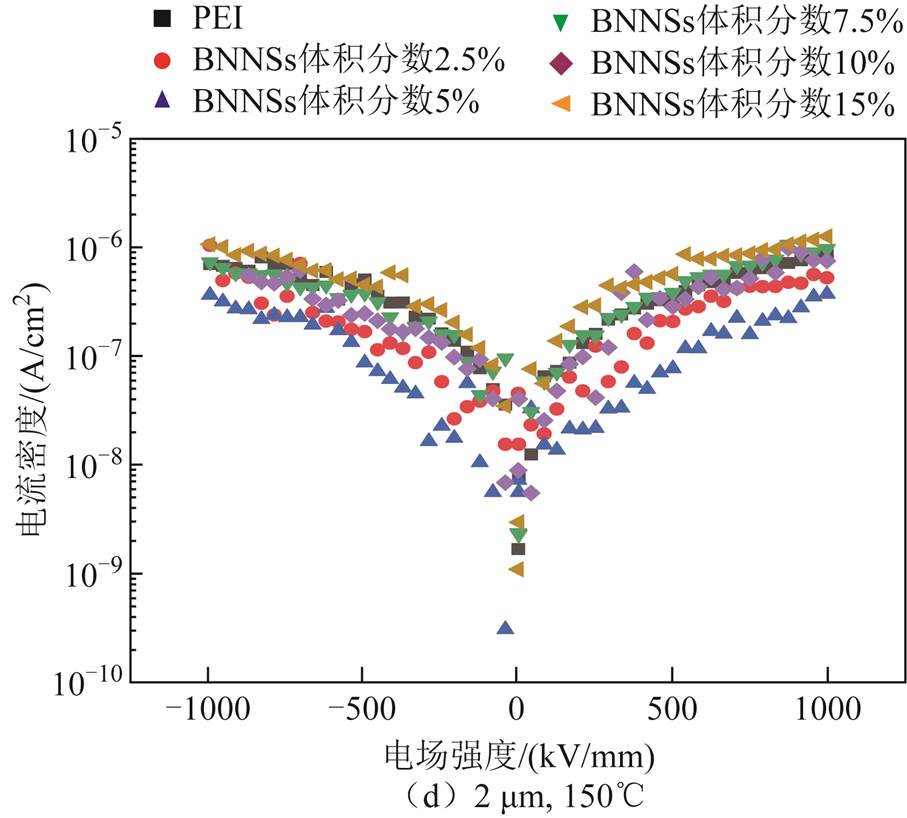

介质薄膜的漏电流密度对其在高电场下长时工作有显著影响,若薄膜漏电流密度较高,随着电压作用时间增长,局部会产生大量焦耳热,当散热速率小于产热速率时,薄膜局部温度会不断升高,最终发生击穿[52]。因此,本文对复合薄膜进行了漏电流测试,结果如图7所示。在相同温度下,随着BNNSs体积分数的增加,由于高势垒BNNSs的添加构建起了有效绝缘屏障,阻碍了载流子的输运,导致漏电流密度降低。随后在体积分数5%时达到临界值,继续添加BNNSs造成局部团聚,电场发生畸变。而体积分数为10%以上的较高含量BNNSs在较大区域形成一个整体的界面势垒,重新形成对载流子的有效阻挡。而在相同体积分数下,温度的升高伴随着漏电流密度的增大,这与载流子的热激发有关。对比不同粒径BNNSs填充下的性能,小粒径显示出了更好的绝缘性能,拥有更低的漏电流密度,其产生的焦耳热更少,高温下拥有更强的工作稳定性。这归因在同样单位体积下,小粒径的BNNSs比大粒径填充产生的界面缺陷数量更少。

图7 复合薄膜漏电流密度

Fig.7 Composite film leakage current density

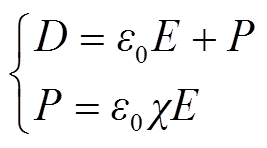

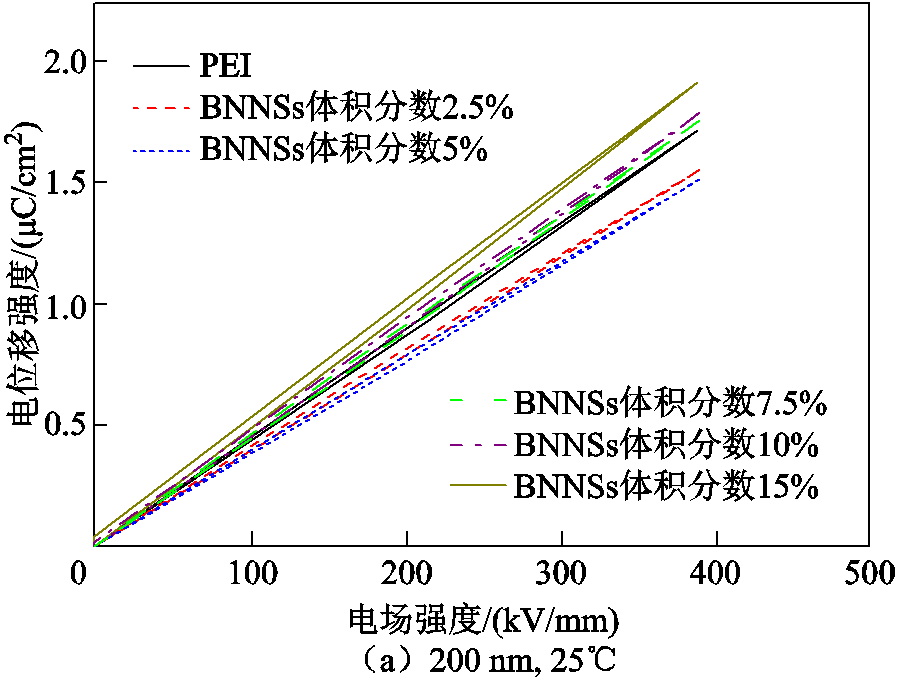

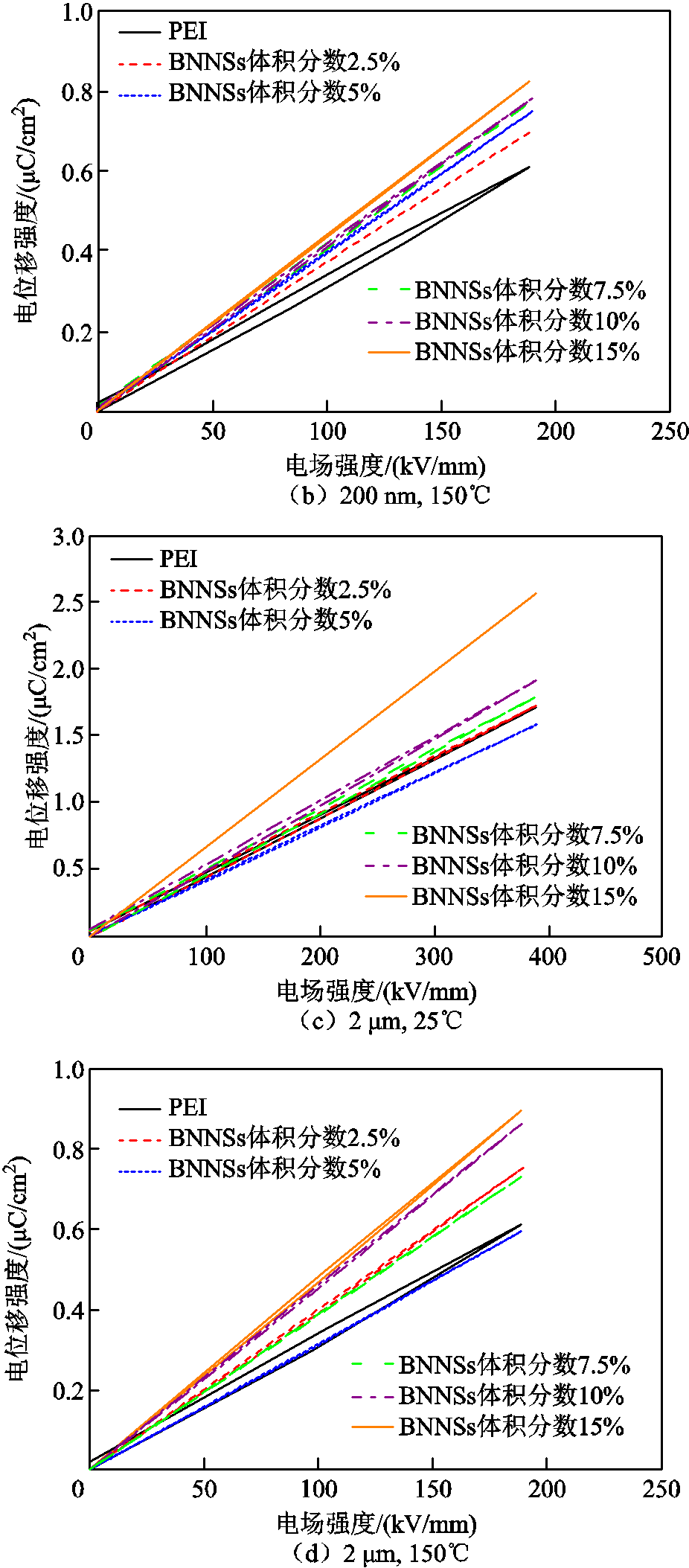

对复合介质进行储能特性测试,得到如图8所示的复合薄膜的极化特性曲线,进一步分析介质薄膜的极化情况。电位移表达式为

(2)

(2)

式中,D为电位移;E为电场强度;e0为真空介电常数,其值为8.85×10-12 F/m;P为极化强度; 为电介质极化率。由电位移表达式可以发现,电位移和电介质的极化强度成正比,而极化程度又由介电常数决定,因此追求高电位移必需要提高介质的介电常数。

为电介质极化率。由电位移表达式可以发现,电位移和电介质的极化强度成正比,而极化程度又由介电常数决定,因此追求高电位移必需要提高介质的介电常数。

图8 复合薄膜的极化特性

Fig.8 Polarization characteristics of composite film

如图8所示,复合介质薄膜的极化程度在相同温度下随着体积分数的增加呈现先降低后增加的趋势。两种不同粒径的BNNSs均在15%的体积分数下获得了最大极化强度,其中在常温390 kV/mm电场强度下,介质薄膜获得了最大的电位移。这归因于填料的团聚效应和界面的增加对极化强度的影响;而在高温190 kV/mm电场强度下,两种不同粒径填充的复合介质薄膜最大极化程度都大幅度下降超过了50%,归因于高温下击穿场强下降,从而使最大极化程度降低。此外,复合薄膜整体表现出了较低的剩余极化,这归因于PEI的固有特性[53]。

通过对电滞回线积分得到材料的储能密度和储能效率。本文中的电介质为线性电介质,其储能密度计算公式为

(3)

(3)

式中,Ue为储能密度;er为介质相对介电常数。

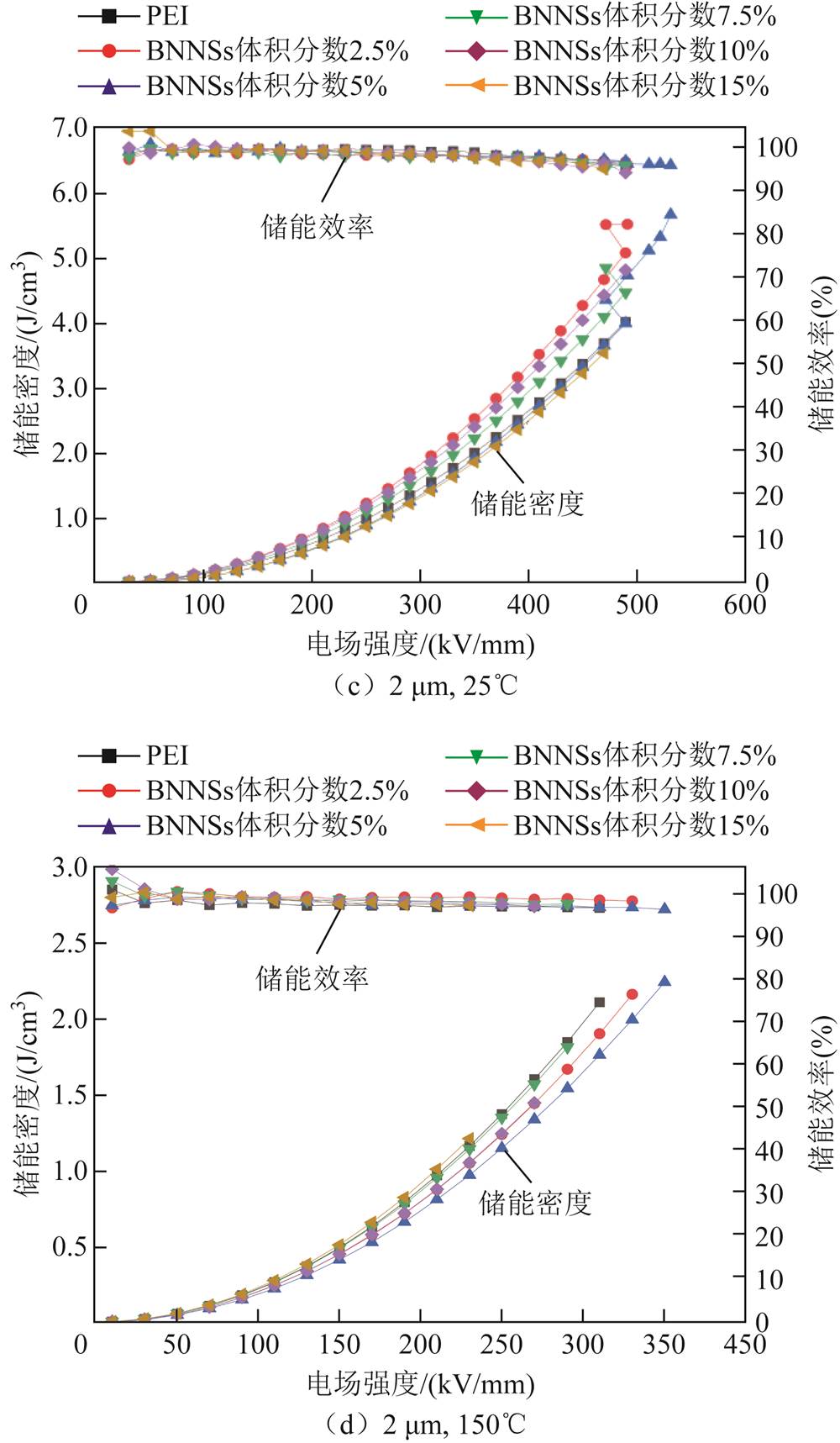

复合薄膜储能特性图9所示,总体上看,随着BNNSs体积分数的不断提升,复合薄膜储能密度和储能效率先增大后减小,在体积分数为5%时达到了最大值。特别是在常温下小粒径BNNSs填充的复合薄膜在580 kV/mm的电场强度下达到了5.6 J/cm3的储能密度和97%的储能效率,相较填充大粒径BNNSs储能效率提升了约15%。随着温度上升到150℃,填充两种不同粒径的复合薄膜储能效率甚至均有少量提升。这意味着复合薄膜在高温下依旧保持了工作稳定性。而随着温度的升高,小粒径填充的复合薄膜表现出更优异的性能,在储能密度相差不大的情况下,储能效率一直保持在95%以上。这是由于少量BNNSs的填充,载流子注入势垒获得提高,内部电场分布得到优化,并且在体积分数为5%时达到最优内部电场分布,击穿场强达到最高。

图9 复合薄膜储能特性

Fig.9 Energy storage characteristics of composite film

另外可以看到在相同温度下随着BNNSs体积分数的增加,储能效率先升高后降低,在体积分数为5%时达到最高,这与上述填料的团聚有关。而在相同体积分数下,随着温度的升高,储能效率不断降低。这一方面是由于在高温下分子热运动加剧,从外界获得的能量使载流子更容易跃迁到高能级,造成漏电流密度增大;另一方面因为温度升高,介质损耗增大也影响了储能效率。

为了比较两种粒径的优劣,分别在常温25℃和高温150℃下整理了掺杂5%体积分数的两种粒径复合薄膜相关性能的各项数据,制成如图10所示的雷达图。图中紫色面积的大小代表了该粒径下复合薄膜的综合性能。在25℃下,掺杂小粒径BNNSs的复合薄膜在击穿场强上明显优于掺杂大粒径BNNSs的复合薄膜,这意味着小粒径复合薄膜能够在拥有几乎相同的储能密度下承受更高的外部工作电压。另外,在150℃的高温下,掺杂小粒径BNNSs的复合薄膜虽然介质损耗高于掺杂大粒径BNNSs的复合薄膜,但掺杂小粒径复合薄膜储能密度更高。因此,掺杂小粒径BNNSs复合薄膜表现出更优秀的综合性能。

图10 掺杂体积分数为5%时的性能对比

Fig.10 Performance comparison with 5% volume fraction

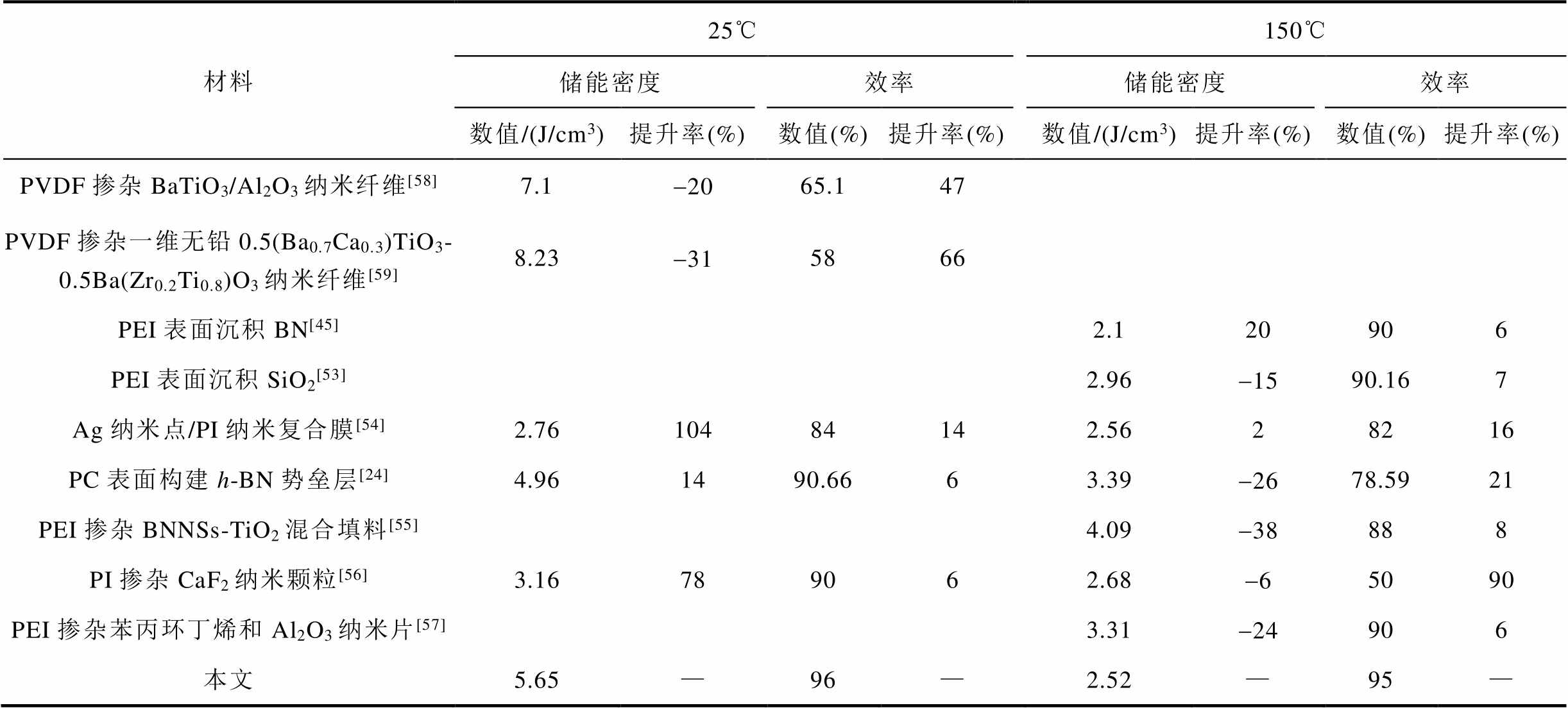

为了对比本文与近年相关成果,加入了在不同工作温度下储能密度与效率的对比,结果见表1[24,45,53-59]。尽管聚偏二氟乙烯(Polyvinylidene Difluoride, PVDF)及其共聚物拥有较高的介电常数,但由于PVDF及其共聚物的玻璃化转变温度较低,导致其在高温环境下无法应用。而PEI、PC等耐高温线性聚合物储能密度较低,且高温下效率下降较为严重。从表1中可以看出,尽管大部分相关工作在150℃和400 kV/mm附近时的储能密度能够达到2~3 J/cm3,但是在高温下充放电效率仅有90%左右。本文中掺杂小尺寸的BNNSs复合薄膜在150℃获得了较高的储能密度(2.52 J/cm3)及优异的充放电效率(95%),再次证明了构筑势垒层制备三明治结构策略的有效性。

表1 本文与近年相关研究比较

Tab.1 Comparison with related researches in recent years

材料25℃150℃ 储能密度效率储能密度效率 数值/(J/cm3)提升率(%)数值(%)提升率(%)数值/(J/cm3)提升率(%)数值(%)提升率(%) PVDF掺杂BaTiO3/Al2O3纳米纤维[58]7.1-2065.147 PVDF掺杂一维无铅0.5(Ba0.7Ca0.3)TiO3-0.5Ba(Zr0.2Ti0.8)O3纳米纤维[59]8.23-315866 PEI表面沉积BN[45]2.120906 PEI表面沉积SiO2[53]2.96-1590.167 Ag纳米点/PI纳米复合膜[54]2.7610484142.5628216 PC表面构建h-BN势垒层[24]4.961490.6663.39-2678.5921 PEI掺杂BNNSs-TiO2混合填料[55]4.09-38888 PI掺杂CaF2纳米颗粒[56]3.16789062.68-65090 PEI掺杂苯丙环丁烯和Al2O3纳米片[57]3.31-24906 本文5.65—96—2.52—95—

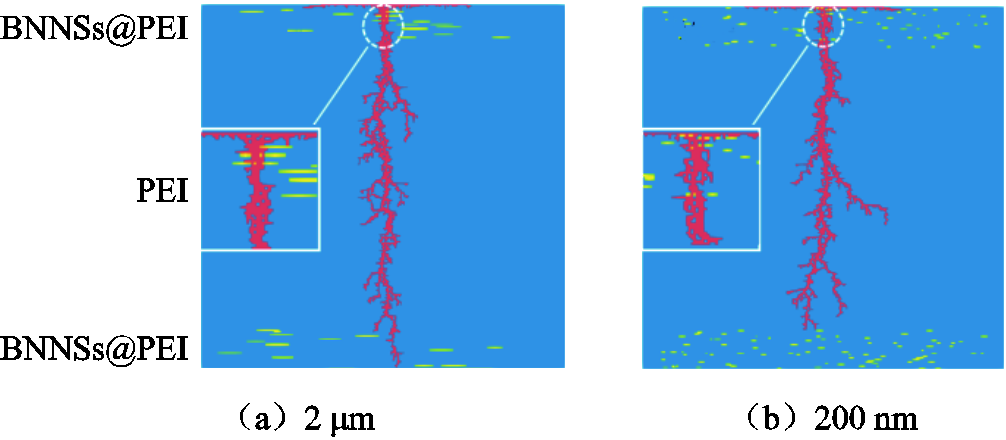

由于实验无法获得影响击穿的全部因素,且三明治势垒层结构及粒径尺寸对击穿路径的影响无法直观得到,因此通过随机击穿模型观测了本文设计的掺杂不同粒径BNNSs的结构策略对击穿性能的提升机制。图11的击穿路径是仿真软件在两种含有不同粒径BNNSs势垒层的复合薄膜两侧施加相同电压,当其中一种完全击穿时和另一种击穿路径发展状况的对比截图。结果显示,两种不同粒径的BNNSs均对击穿路径演化起到了阻碍作用[60]。值得注意的是,通过观察路径顶端的局部放大图,相同体积分数下局部范围内小粒径BNNSs较大粒径数量更多,填料间距离更小,在击穿过程中,击穿路径需要经过纳米片数量更多,被阻碍的概率相应增加。当2 μm BNNSs填充的复合薄膜被完全击穿时,200 nm BNNSs复合薄膜依旧保持了绝缘能力,证明了相同体积分数下小粒径填料对提高复合薄膜绝缘能力具有更好的效果。另外,模拟结果也表明掺杂BNNSs对载流子注入的抑制效果较为明显,为击穿路径提供了更多的障碍和发散概率。

图11 体积分数为5%不同粒径BNNSs对击穿路径的影响

Fig.11 Effect of different particle size BNNSs with volume fraction of 5% on breakdown path

本文将不同粒径的BNNSs掺杂进PEI基体中构建势垒层,放置在纯PEI薄膜两侧制备含有三明治结构的复合薄膜。BNNSs势垒层有效阻挡了电极处载流子注入并且阻碍了击穿路径在复合薄膜内部的发展。三明治结构改善了因无机物掺杂而造成的击穿强度下降,降低了复合薄膜电导率。最后通过随机击穿模型,证实了该结构设计的有效性,阐明了BNNSs粒径尺寸对绝缘性能的调控机制。本文得到结论如下:

1)通过掺杂宽带隙BNNSs构建的势垒层降低了载流子注入的概率,并且三明治结构在击穿路径的演化过程中有明显的阻碍作用,为击穿路径提供了更多的障碍。

2)通过比较添加两种不同粒径BNNSs的复合薄膜可知,小粒径的复合薄膜在综合条件下显示出了更优异的绝缘能力和储能特性。相同体积分数下,小粒径BNNSs颗粒间距更小,对抑制击穿路径更有效。

3)随着填料含量的增加,复合薄膜绝缘性能获得提升,但达到一定掺杂体积分数后继续增加反而会造成薄膜储能性能的下降,这归因于过多填料造成的团聚效应,而本文中掺杂体积分数为5%的BNNSs的复合薄膜表现出了最高的综合性能。

本文制备的掺杂BNNSs的势垒层和三明治结构提升了复合薄膜整体的击穿性能和充放电效率,降低了高温下的电导损耗。并且通过测试填料粒径大小对复合薄膜性能的影响,发现小粒径比大粒径掺杂具有更显著的提升效果。本文制备的复合薄膜对未来高温储能介质领域具有潜在的应用价值。

参考文献

[1] 贺元康, 丁涛, 刘瑞丰, 等. 新能源消纳电量库交易机制的实践与经验[J]. 电力系统自动化, 2021, 45(7): 163-169. He Yuankang, Ding Tao, Liu Ruifeng, et al. Practice and experience of trading mechanism for energy pool of renewable energy accommodation[J]. Automation of Electric Power Systems, 2021, 45(7): 163-169.

[2] 闫佳佳, 滕云, 邱实, 等. 计及供能可靠性动态约束与碳减排的充能型微电网互联系统优化模型[J]. 电工技术学报, 2022, 37(23): 5956-5975. Yan Jiajia, Teng Yun, Qiu Shi, et al. Optimization model of charging microgrid interconnection system considering dynamic constraints of energy supply reliability and carbon emission reduction[J]. Transactions of China Electrotechnical Society, 2022, 37(23): 5956-5975.

[3] 王海鑫, 袁佳慧, 陈哲, 等. 智慧城市车-站-网一体化运行关键技术研究综述及展望[J]. 电工技术学报, 2022, 37(1): 112-132. Wang Haixin, Yuan Jiahui, Chen Zhe, et al. Review and prospect of key techniques for vehicle-station-network integrated operation in smart city[J]. Transactions of China Electrotechnical Society, 2022, 37(1): 112-132.

[4] 何晨可, 朱继忠, 刘云, 等. 计及碳减排的电动汽车充换储一体站与主动配电网协调规划[J]. 电工技术学报, 2022, 37(1): 92-111. He Chenke, Zhu Jizhong, Liu Yun, et al. Coordinated planning of electric vehicle charging-swapping-storage integrated station and active distribution network considering carbon reduction[J]. Transactions of China Electrotechnical Society, 2022, 37(1): 92-111.

[5] Guo Ru, Roscow J I, Bowen C R, et al. Significantly enhanced permittivity and energy density in dielectric composites with aligned BaTiO3 lamellar structures[J]. Journal of Materials Chemistry A, 2020, 8(6): 3135-3144.

[6] Zhang Tian, Chen Xin, Thakur Y, et al. A highly scalable dielectric metamaterial with superior capacitor performance over a broad temperature[J]. Science Advances, 2020, 6(4): eaax6622.

[7] 谢庆, 段祺君, 邵帅, 等. BTO纳米纤维及其等离子体氟化对EP复合材料表面绝缘特性的影响[J]. 中国电机工程学报, 2020, 40(12): 4051-4063. Xie Qing, Duan Qijun, Shao Shuai, et al. Effect of Barium titanate nanofibers and plasma fluorination on surface insulation properties of epoxy resin composites[J]. Proceedings of the CSEE, 2020, 40(12): 4051-4063.

[8] 毛玲, 邓思文, 赵登辉, 等. 新能源汽车监测平台在行驶和充电场景中的应用与思考[J]. 电工技术学报, 2022, 37(1): 48-57. Mao Ling, Deng Siwen, Zhao Denghui, et al. Application and thinking of big data technology of new energy vehicle monitoring platform in driving and charging scenarios[J]. Transactions of China Electrotechnical Society, 2022, 37(1): 48-57.

[9] Wu Xudong, Song Guanghui, Zhang Xiaofei, et al. Multilayer polyetherimide films incorporating alumina nanolayers for dielectric capacitors[J]. Chemical Engineering Journal, 2022, 450: 137940.

[10] 刘金刚, 张秀敏, 田付强, 等. 耐高温聚合物电介质材料的研究与应用进展[J]. 电工技术学报, 2017, 32(16): 14-24. Liu Jingang, Zhang Xiumin, Tian Fuqiang, et al. Recent progress of research and development for high-temperature resistant polymer dielectrics[J]. Transactions of China Electrotechnical Society, 2017, 32(16): 14-24.

[11] Zhang Zhongbo, Litt M H, Zhu Lei. Understanding the paraelectric double hysteresis loop behavior in mesomorphic even-numbered nylons at high temperatures[J]. Macromolecules, 2017, 50(15): 5816-5829.

[12] Li Qi, Chen Lei, Gadinski M R, et al. Flexible high-temperature dielectric materials from polymer nanocomposites[J]. Nature, 2015, 523(7562): 576-579.

[13] 李琦, 李曼茜. 高温聚合物薄膜电容器介电材料评述与展望[J]. 高电压技术, 2021, 47(9): 3105-3123. Li Qi, Li Manxi. High-temperature polymer dielectrics for film capacitors: review and prospect[J]. High Voltage Engineering, 2021, 47(9): 3105-3123.

[14] 叶润峰, 裴家耀, 郑明胜, 等. 高介电聚丙烯基纳米复合薄膜介电及储能性能抗老化特性[J]. 电工技术学报, 2020, 35(16): 3529-3538. Ye Runfeng, Pei Jiayao, Zheng Mingsheng, et al. Anti-aging characteristics of dielectric and energy storage of high dielectric polypropylene based nanocomposite films[J]. Transactions of China Electrotechnical Society, 2020, 35(16): 3529-3538.

[15] Bai Yingxin, Cheng Zhongyang, Bharti V, et al. High-dielectric-constant ceramic-powder polymer compo-sites[J]. Applied Physics Letters, 2000, 76(25): 3804-3806.

[16] Wang Changchun, Song Jiaofan, Bao Huimin, et al. Enhancement of electrical properties of ferroelectric polymers by polyaniline nanofibers with controllable conductivities[J]. Advanced Functional Materials, 2008, 18(8): 1299-1306.

[17] Ai Ding, Li He, Zhou Yao, et al. Tuning nanofillers in in situ prepared polyimide nanocomposites for high-temperature capacitive energy storage[J]. Advanced Energy Materials, 2020, 10(16): 1903881.

[18] Hayashida K. Highly improved dielectric properties of polymer/α-Fe2O3 composites at elevated temperatures [J]. RSC Advances, 2016, 6(69): 64871-64878.

[19] Wang Jingang, Ma Fengcai, Sun Mengtao. Graphene, hexagonal boron nitride, and their heterostructures: properties and applications[J]. RSC Advances, 2017, 7(27): 16801-16822.

[20] Kim K K, Hsu A, Jia Xiaoting, et al. Synthesis and characterization of hexagonal boron nitride film as a dielectric layer for graphene devices[J]. ACS Nano, 2012, 6(10): 8583-8590.

[21] Chen Xiaolin, Cheng Yonghong, Wu Kai, et al. Dielectric spectroscopy analysis of the h-BN ceramic[J]. Journal of Physics D: Applied Physics, 2007, 40(19): 6034-6038.

[22] Pang Hua, Pang Wenhui, Zhang Bo, et al. Excellent microwave absorption properties of the h-BN-GO-Fe3O4 ternary composite[J]. Journal of Materials Chemistry C, 2018, 6(43): 11722-11730.

[23] Merlo A, Mokkapati V R S S, Pandit S, et al. Boron nitride nanomaterials: biocompatibility and bio-applications[J]. Biomaterials Science, 2018, 6(9): 2298-2311.

[24] Liu Guang, Zhang Tiandong, Feng Yu, et al. Sandwich-structured polymers with electrospun boron nitrides layers as high-temperature energy storage dielectrics[J]. Chemical Engineering Journal, 2020, 389: 124443.

[25] Li Meng, Wang Mengjie, Hou Xiao, et al. Highly thermal conductive and electrical insulating polymer composites with boron nitride[J]. Composites Part B: Engineering, 2020, 184: 107746.

[26] Xue Pengjie, Liu Shilin, Bian Jianjiang. Effects of polymorphic form and particle size of SiO2 fillers on the properties of SiO2-PEEK composites[J]. Journal of Advanced Dielectrics, 2021, 11(4): 2150021.

[27] Tang Haixiong, Lin Yirong, Sodano H A. Synthesis of high aspect ratio BaTiO3 nanowires for high energy density nanocomposite capacitors[J]. Advanced Energy Materials, 2013, 3(4): 451-456.

[28] Yao Lingmin, Pan Zhongbin, Zhai Jiwei, et al. High-energy-density with polymer nanocomposites containing of SrTiO3 nanofibers for capacitor application[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 48-54.

[29] Zhu Yingke, Yao Hao, Jiang Pingkai, et al. Two-dimensional high-k nanosheets for dielectric polymer nanocomposites with ultrahigh discharged energy density[J]. The Journal of Physical Chemistry C, 2018, 122(32): 18282-18293.

[30] Tuncer E. Electrical properties of polyetherimide thin films: Non-parametric dielectric response analysis with distribution of relaxation times[J]. The European Physical Journal E, 2017, 40(6): 66.

[31] Pfeiffenberger N, Milandou F, Niemeyer M, et al. High temperature dielectric polyetherimide film development[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, 25(1): 120-126.

[32] Yue Dong, Feng Yu, Liu Xiaoxu, et al. Prediction of energy storage performance in polymer composites using high-throughput stochastic breakdown simulation and machine learning[J]. Advanced Science, 2022, 9(17): e2105773.

[33] Wang Jianjun, Ma Xingqiao, Li Qun, et al. Phase transitions and domain structures of ferroelectric nanoparticles: phase field model incorporating strong elastic and dielectric inhomogeneity[J]. Acta Materialia, 2013, 61(20): 7591-7603.

[34] Huang Kuan, Liang Liangbo, Chai Songhai, et al. Aminopolymer functionalization of boron nitride nanosheets for highly efficient capture of carbon dioxide[J]. Journal of Materials Chemistry A, 2017, 5(31): 16241-16248.

[35] Kang Yue, Li Wangchang, Ma Tian, et al. Microwave-constructed honeycomb architectures of h-BN/rGO nano-hybrids for efficient microwave conversion[J]. Composites Science and Technology, 2019, 174: 184-193.

[36] Yu Jingjing, Zhao Wenjie, Wu Yinghao, et al. Tribological properties of epoxy composite coatings reinforced with functionalized C-BN and H-BN nanofillers[J]. Applied Surface Science, 2018, 434: 1311-1320.

[37] Luo Suibin, Yu Junyi, Yu Shuhui, et al. Significantly enhanced electrostatic energy storage performance of flexible polymer composites by introducing highly insulating-ferroelectric microhybrids as fillers[J]. Advanced Energy Materials, 2019, 9(5): 1803204.

[38] Yang Yang, Sun Haoliang, Yin Di, et al. High performance of polyimide/CaCu3Ti4O12@Ag hybrid films with enhanced dielectric permittivity and low dielectric loss[J]. Journal of Materials Chemistry A, 2015, 3(9): 4916-4921.

[39] Guo Ru, Luo Hang, Zhai Di, et al. Bilayer structured PVDF-based composites via integrating BaTiO3 nanowire arrays and BN nanosheets for high energy density capacitors[J]. Chemical Engineering Journal, 2022, 437: 135497.

[40] 吴加雪, 唐超, 张天栋, 等. 氮化硼和氧化锌晶须共掺杂环氧树脂复合材料的导热与绝缘性能[J]. 复合材料学报, 2022, 39(5): 2183-2191. Wu Jiaxue, Tang Chao, Zhang Tiandong, et al. Thermal conductivity and electrical insulating properties of epoxy composites mixed with boron nitride and zinc oxide whisker[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2183-2191.

[41] Dang Zhimin, Yuan Jinkai, Zha Junwei, et al. Fundamentals, processes and applications of high-permittivity polymer-matrix composites[J]. Progress in Materials Science, 2012, 57(4): 660-723.

[42] Jin Y, Gwak Y, Gerhardt R A. Effects of nanoparticles size and interactions on dielectric properties of polymer matrix flexible dielectric nanocomposites[J]. Advanced Composite Materials, 2020, 29(3): 235-246.

[43] 王威望, 李盛涛, 刘文凤. 聚合物纳米复合电介质的击穿性能[J]. 电工技术学报, 2017, 32(16): 25-36. Wang Weiwang, Li Shengtao, Liu Wenfeng. Dielectric breakdown of polymer nanocomposites[J]. Transactions of China Electrotechnical Society, 2017, 32(16): 25-36.

[44] Shi Zhicheng, Wang Jing, Mao Fan, et al. Significantly improved dielectric performances of sandwich-structured polymer composites induced by alternating positive-k and negative-k layers[J]. Journal of Materials Chemistry A, 2017, 5(28): 14575-14582.

[45] Azizi A, Gadinski M R, Li Qi, et al. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials[J]. Advanced Materials, 2017, 29(35): 1701864.

[46] Yuan Chao, Zhou Yao, Zhu Yujie, et al. Polymer/ molecular semiconductor all-organic composites for high-temperature dielectric energy storage[J]. Nature Communications, 2020, 11: 3919.

[47] Liu Shaohui, Xue Shuangxi, Shen Bo, et al. Reduced energy loss in poly (vinylidene fluoride) nano-composites by filling with a small loading of core-shell structured BaTiO3/SiO2 nanofibers[J]. Applied Physics Letters, 2015, 107(3): 032907.

[48] Shen Zhonghui, Wang Jianjun, Jiang Jianyong, et al. Phase-field model of electrothermal breakdown in flexible high-temperature nanocomposites under extreme conditions[J]. Advanced Energy Materials, 2018, 8(20): 1800509.

[49] Chen Hui, Hou Yafei, Wu Zhijie, et al. Simultaneous enhancement of discharge energy density and efficiency in the PMMA and PVDF blend films via introducing the Ni(OH)2 nanosheets[J]. Journal of Alloys and Compounds, 2021, 862: 158688.

[50] 南江, 刘诚威, 夏平安. 聚四氟乙烯/纳米碳化硅改性复合材料的制备及其介电特性[J]. 电工技术学报, 2021, 36(增刊1): 1-7. Nan Jiang, Liu Chengwei, Xia Pingan. Preparation and dielectric characteristics of nano-SiC/PTFE composite [J]. Transactions of China Electrotechnical Society, 2021, 36(S1): 1-7.

[51] 李鹏新, 崔浩喆, 邢照亮, 等. 环氧/POSS复合电介质介电与热学性能[J]. 电工技术学报, 2022, 37(2): 291-298. Li Pengxin, Cui Haozhe, Xing Zhaoliang, et al. Dielectric and thermal properties of epoxy/POSS composites[J]. Transactions of China Electrotechnical Society, 2022, 37(2): 291-298.

[52] Li Qi, Liu Feihua, Yang Tiannan, et al. Sandwich-structured polymer nanocomposites with high energy density and great charge-discharge efficiency at elevated temperatures[J]. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(36): 9995-10000.

[53] Zhang Tiandong, Yang Lianyin, Ruan Jinyu, et al. Improved high-temperature energy storage performance of PEI dielectric films by introducing an SiO2 insulating layer[J]. Macromolecular Materials and Engineering, 2021, 306(12): 2100514.

[54] Xing Shuang, Pan Zhongbin, Wu Xiaofeng, et al. Enhancement of thermal stability and energy storage capability of flexible Ag nanodot/polyimide nanocomposite films via in situ synthesis[J]. Journal of Materials Chemistry C, 2020, 8(36): 12607-12614.

[55] Ding Xiangping, Pan Zhongbin, Zhang Yong, et al. Regulation of interfacial polarization and local electric field strength achieved highly energy storage performance in polyetherimide nanocomposites at elevated temperature via 2D hybrid structure[J]. Advanced Materials Interfaces, 2022, 9(28): 2201100.

[56] Li Liuting, Dong Jiufeng, Hu Renchao, et al. Wide-bandgap fluorides/polyimide composites with enhanced energy storage properties at high temperatures[J]. Chemical Engineering Journal, 2022, 435: 135059.

[57] Li He, Ai Ding, Ren Lulu, et al. Scalable polymer nanocomposites with record high-temperature capacitive performance enabled by rationally designed nanostructured inorganic fillers[J]. Advanced Materials, 2019, 31(23): 1900875.

[58] Liu Shaohui, Wang Jiao, Shen Bo, et al. Enhanced discharged energy density and efficiency of poly(vinylidene fluoride) nanocomposites through a small loading of core-shell structured BaTiO3@Al2O3 nanofibers[J]. Ceramics International, 2017, 43(1): 585-589.

[59] Pan Zhongbin, Yao Lingmin, Zhai Jiwei, et al. Ultrafast discharge and enhanced energy density of polymer nanocomposites loaded with 0.5(Ba0.7Ca0.3) TiO3-0.5Ba(Zr0.2Ti0.8)O3 one-dimensional nanofibers[J]. ACS Applied Materials & Interfaces, 2017, 9(16): 14337-14346.

[60] 郑明胜, 查俊伟, 党智敏. 新型高储能密度聚合物基绝缘材料[J]. 电工技术学报, 2017, 32(16): 37-43. Zheng Mingsheng, Zha Junwei, Dang Zhimin. Advanced polymer-based insulating materials with high energy storage density[J]. Transactions of China Electrotechnical Society, 2017, 32(16): 37-43.

Abstract Faced with the application requirements of various electromagnetic devices and new energy vehicle inverters, film capacitors that combine easy processability with high charge/discharge density and efficiency are receiving more attention. However, the commonly used commercial BOPP films on the market cannot be used in high temperature applications due to their own structural limitations, and the charge/discharge energy density and efficiency are also low, so the development of high energy storage density film capacitors for high temperature applications is the future development trend. In order to solve the problem of poor energy storage performance due to the low breakdown field strength (Eb) of pure polymer energy storage films, composite structural design of broadband inorganic materials with polymers is an effective way.

In this work, in order to reduce the effects of poor compatibility between inorganic and polymer surfaces due to excessive differences in physicochemical properties, resulting in electric field distortion, polyetherimide (PEI) was chosen as the matrix, BNNSs with wide forbidden bands and high thermal conductivity were used as fillers, a potential barrier layer doped with BNNSs was constructed on both sides of the pure PEI film by electrostatic spinning, and sandwich structured polymer-based composite films were designed and prepared. By increasing the overall barrier height of the composite film and suppressing the carrier injection and internal breakdown path development at the electrode at high temperature, the Eb of the composite film is finally enhanced and the conductivity loss is reduced. Moreover, by comparing the doping of different particle sizes of BNNSs, it was found that the filler size plays a role in regulating the microstructure and macroscopic properties in the structure design, and eventually the smaller size of 200 nm BNNSs obtained higher energy storage density and charge/discharge efficiency, and the energy storage density and charge/discharge efficiency of the composite film filled with 5% BNNSs reached 5.65 J/cm3 and 96% efficiency at room temperature; even at 150℃, the energy storage density of 2.52 J/cm3 and 95% charge/discharge efficiency can be achieved.

In addition, the breakdown mechanism of polymer-based composite films is complex, and the physical process of breakdown cannot be captured experimentally. Therefore, this work simulated the breakdown path evolution of polymer-based composite films filled with BNNSs of different particle sizes using a stochastic breakdown model and found the following conclusions: (1) The potential barrier layer on both sides of the pure PEI effectively reduces the carrier injection at the electrode/dielectric and its transport inside the dielectric, especially the sandwich structure, which has a significant inhibitory effect during the development of the breakdown path, while the inorganic material doped in the form of nanosheets also provides this resistance. (2) The composite films doped with smaller sized BNNSs have higher breakdown strength, attributed to the higher number of smaller sized BNNSs at the same volume fraction, providing a higher chance of hindrance. (3) Excessive filler volume fraction will lead to local agglomeration in the composite film, resulting in distortion of the local electric field and severe degradation of Eb. In this work, the composite film with 5% BNNSs exhibited the optimal energy storage performance.

Keywords:Dielectric film, polyetherimide, boron nitride, dielectric properties, energy storage density

DOI: 10.19595/j.cnki.1000-6753.tces.221888

中图分类号:TM211

国家自然科学基金项目(52177017)和黑龙江省自然科学基金优秀青年项目(YQ2021E036)资助。

收稿日期 2022-10-07

改稿日期 2023-02-10

冯 宇 男,1987年生,教授,博士生导师,研究方向为聚合物基储能型复合介质、封装用导热绝缘介质等。E-mail:fengyu@hrbust.edu.cn

迟庆国 男,1981年生,教授,博士生导师,研究方向为高储能密度聚合物基绝缘介质与器件、电力电子器件封装绝缘等。E-mail:qgchi@hrbust.edu.cn(通信作者)

(编辑 李 冰)