图1 传统CPM电机结构演化示意图

Fig.1 Schematic diagram of topology evolution for the conventional CPM machine

摘要 与传统表贴式永磁(SPM)电机相比,交替极永磁(CPM)电机部分磁极被转子铁心极替代,因此具有相对较高的永磁体利用率,且具有与SPM相媲美的转矩输出能力。该文对CPM电机拓扑演化规律进行分析,总结CPM电机不同永磁结构下的磁极特征。在此基础上,量化分析不同永磁结构下CPM电机气隙磁通密度调制谐波的转矩贡献,揭示不同永磁结构对CPM电机气隙磁场调制效应的影响规律。制作了一台CPM样机并进行了样机试验,验证了理论分析与仿真的可靠性。

关键词:磁场调制效应 交替极 转矩量化分析 永磁电机

永磁电机以其高效率、高转矩/功率密度等显著优点,被广泛应用于交通运载、航空航天、智能制造等国家重点战略发展领域。因此,研发高性能永磁电机已成为电机行业研究的重中之重。但传统永磁体多采用稀土材料,而国内稀土矿储存量有限,且近年来国际贸易摩擦不断,稀土永磁材料价格不断攀升。因此,如何在实现高性能的同时提高永磁体的利用率,成为永磁电机领域的一大研究热点[1]。

与传统表贴式永磁(Surfaced-mounted Permanent Magnet, SPM)结构相比,交替极永磁(Consequent- pole Permanent Magnet, CPM)结构的N或S极永磁磁极被铁心替代,可显著降低永磁体用量,并具有与传统SPM结构相媲美的电磁性能,因此多种形式的CPM电机被广泛研究[2]。由于CPM电机永磁体单极性分布,磁动势分布呈现偏置现象;同时定转子铁心呈现双边开槽,使其气隙磁导分布复杂,因此CPM电机较之传统SPM电机具有相对较多的气隙磁通密度谐波[3]。

除传统表嵌式CPM结构外,多种不同永磁结构的内置式CPM电机也被广泛研究。文献[4]提出一种近似梯形结构CPM电机,与传统SPM结构相比,永磁用量可降低20 %。文献[5]提出一种Halbach阵列CPM直线结构,在永磁体用量降低27.5 %时具有与SPM电机相媲美的转矩能力。将传统表嵌式CPM结构进一步延伸到内置式结构中,可形成一字型[6]、V型[7-9]、U型[10-11]、Spoke型[12-13]、W型[14]及▽型[15]CPM电机。此外,将传统表嵌式结构与内置式结构进行结合,可形成混合磁极CPM电机[16-18]。仿真与试验表明,与传统内置式结构相比,内置式和混合磁极CPM电机具有较好的弱磁能力、基本持平的高效率区域及较高的永磁体利用率。

近年来,磁场调制理论被延伸到多种不同电机中。根据调制器、电枢及励磁磁场三要素,可将游标、磁通反向、磁通切换等多种电机归为磁场调制电机[19]。将磁齿轮调制效应进一步延伸到游标、磁通切换及双永磁电机中,研究表明其具有相同的运行原理,并基于此调制原理,提出一种双馈型双定子电机[20]。将单元电机抽象为励磁源、调制器及滤波器三要素的级联,构建调制算子函数,从而实现电枢及励磁磁场极对数的解耦,文献[21-22]初步提出了电机气隙磁场调制统一理论,并对多种电机进行了定性与定量分析,验证了理论的有效性。

尽管多种不同永磁结构的CPM电机被广泛研究[2-18],但其潜在的拓扑演化规律及不同永磁体结构带来的内部气隙磁场调制机理仍需进一步阐明。基于此,本文以传统表嵌式CPM电机为例,研究并总结了CPM结构拓扑演化规律;采用麦克斯韦应力张量法(Maxwell Stress Tensor Method, MSTM)量化分析气隙磁通密度各次谐波转矩贡献以揭示其内在气隙磁场调制机理;最后,加工制作了一台CPM样机并开展样机试验。

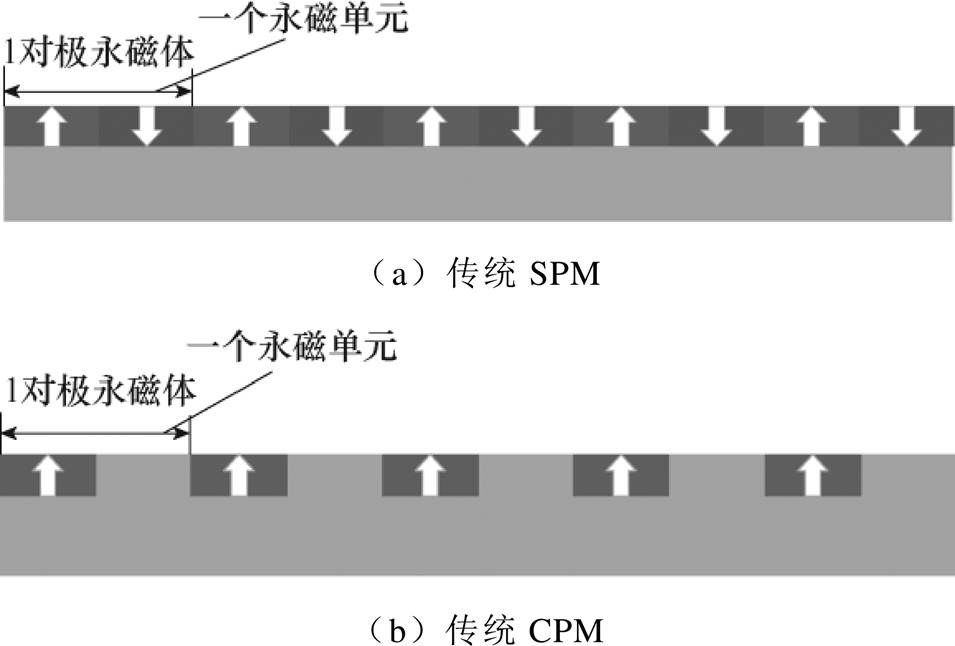

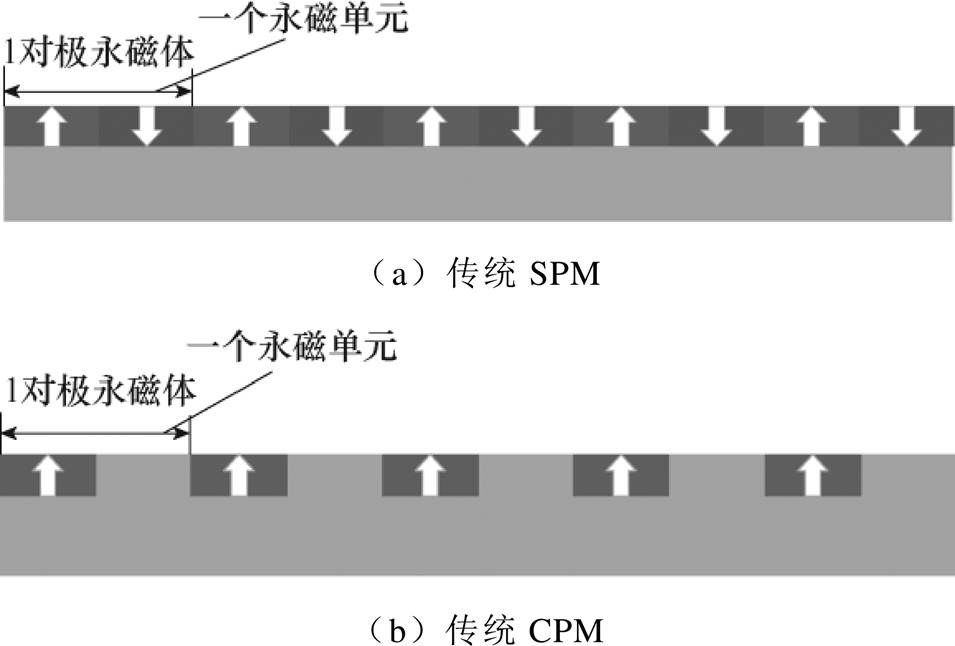

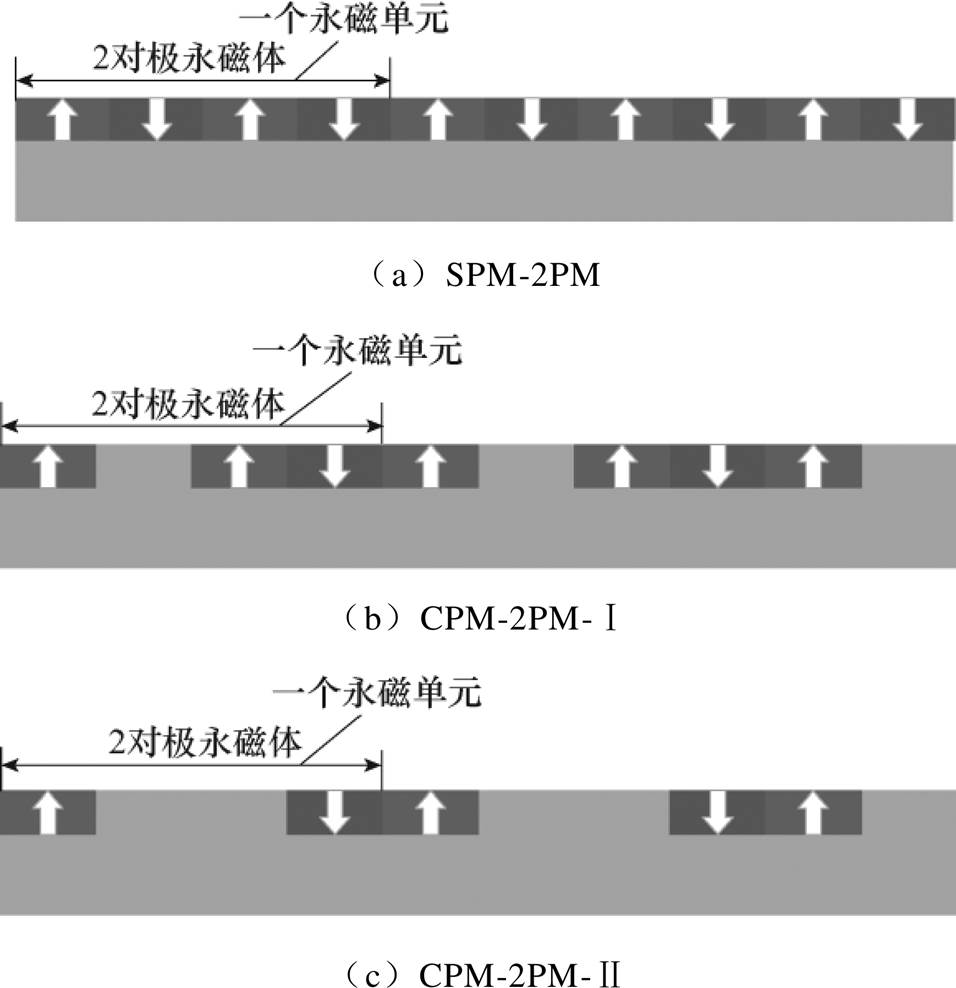

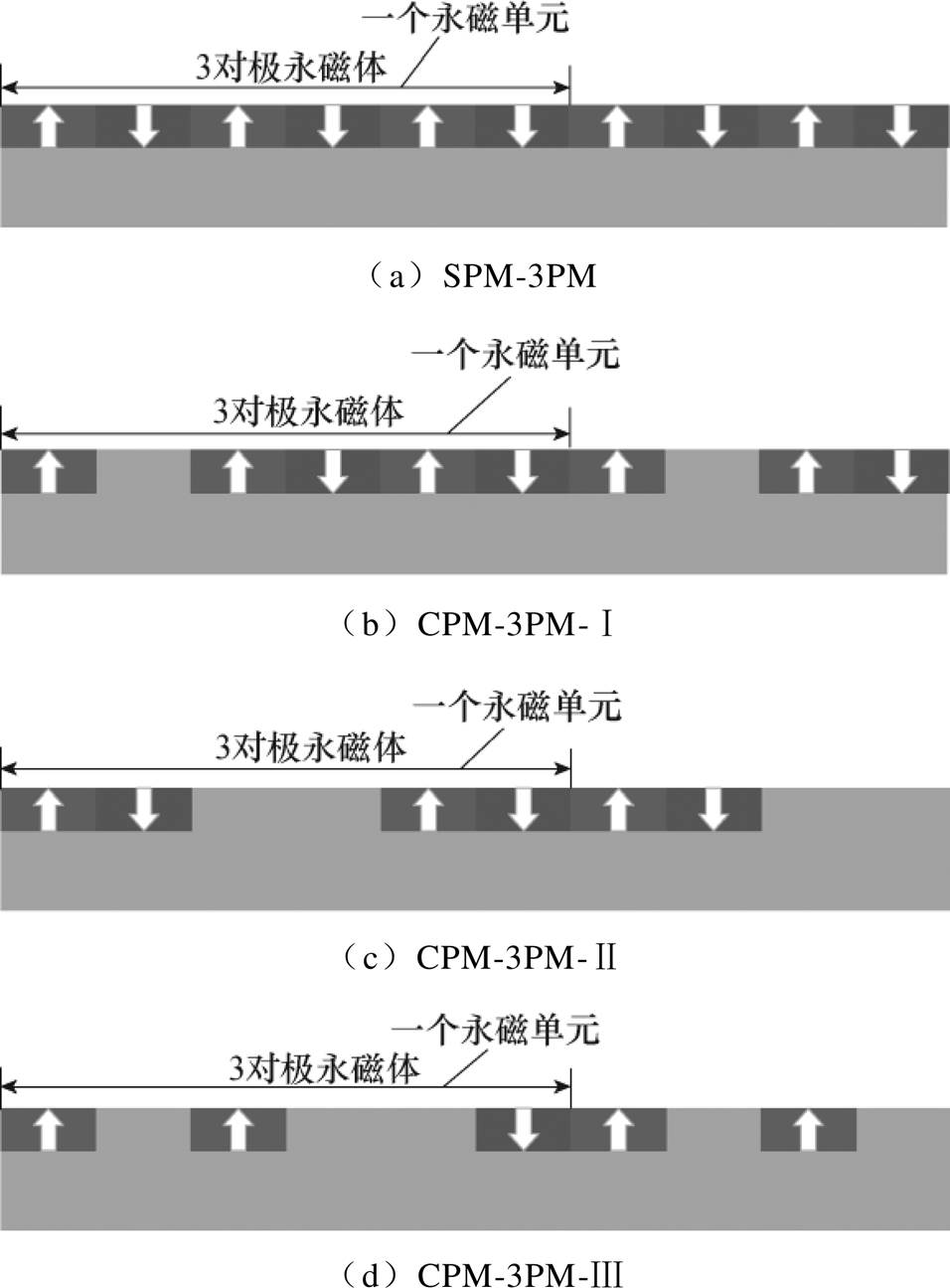

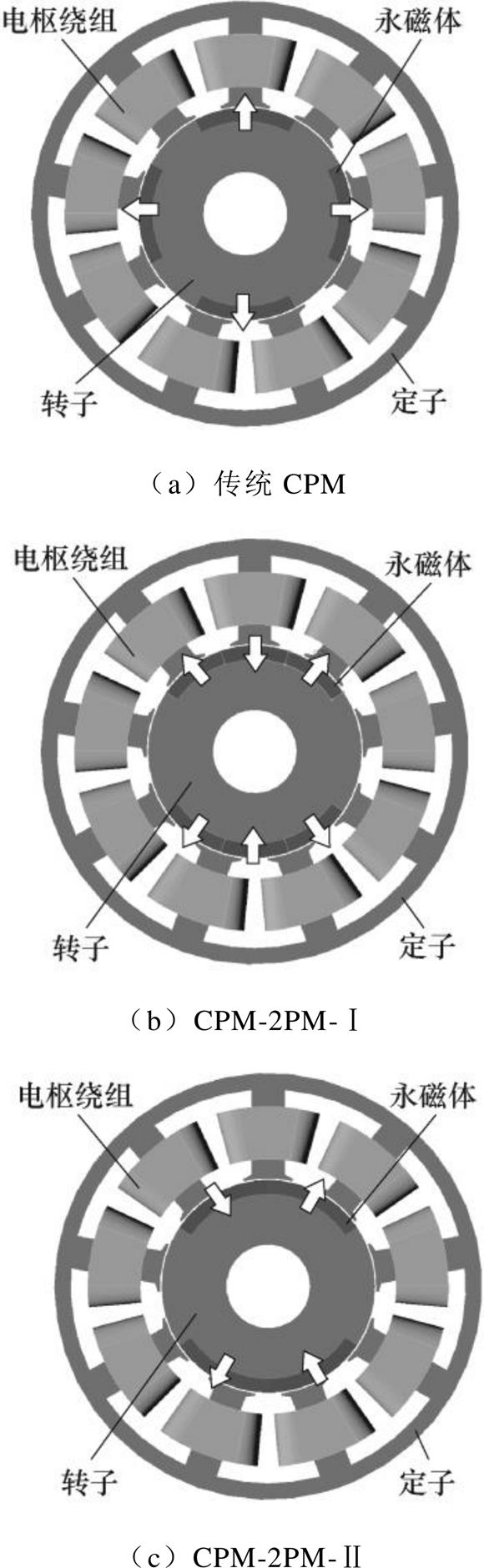

对于传统SPM电机,一个N和S极永磁体形成一对极,即为一个永磁单元,当其中一块永磁体被转子铁心替代时,即可形成传统的CPM电机,其拓扑演化示意图如图1所示。由传统CPM电机演化可知,将一个永磁单元中的一对极永磁体延伸到两对极永磁体时,其拓扑演化示意图如图2所示。分析可知,将其中一块或两块永磁体由铁心替代时,可形成两种典型的非传统表嵌式CPM结构,分别如图2b和图2c所示。同理,当一个永磁单元包括三对极永磁体时,其拓扑演化示意图如图3所示。分析可知,可将其中的一块、两块或三块永磁体由转子铁心替换,形成三种典型的非传统表嵌式CPM结构。

图1 传统CPM电机结构演化示意图

Fig.1 Schematic diagram of topology evolution for the conventional CPM machine

图2 一个永磁单元具有2对极永磁体时CPM电机结构演化示意图

Fig.2 Schematic diagram of topology evolution for the CPM machine with two pole-pair PMs in one PM unit

图3 一个永磁单元具有3对极永磁体时CPM电机结构演化示意图

Fig.3 Schematic diagram of topology evolution for the CPM machine with three pole-pair PMs in one PM unit

对表嵌式CPM电机拓扑演化规律进行总结,可获得以下结论:

(1)一个永磁单元包括n(n≥2)对极永磁体时,其可形成n种典型的非传统表嵌式CPM结构。

(2)一个永磁单元包括n(n≥2)对极永磁体的非传统表嵌式CPM电机,其转子调制齿数最多为n-1个。

(3)一个永磁单元包括n(n≥2)对极永磁体时,一个永磁单元中的S极(或N极)和相邻的N、S极可被一个转子铁心极替换,因此一个永磁单元中转子调制齿为1时的非传统表嵌式CPM结构均有两种。

传统表嵌式CPM电机一对极永磁体(一个永磁单元)中S极(或N极)被铁心替代,因此永磁体极对数与转子调制齿数相等,而非传统表嵌式CPM电机一个永磁单元包括n(n≥2)对极永磁体,导致其转子调制齿数始终小于永磁体极对数。

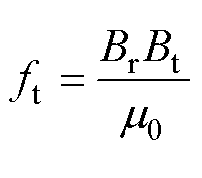

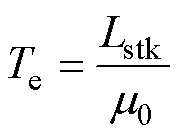

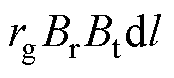

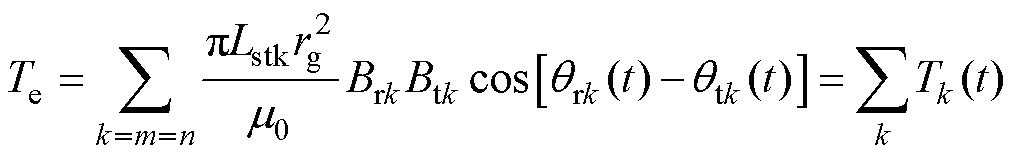

由MSTM可知,旋转电机气隙切向力密度ft可表示[23]为

(1)

(1)

式中,m0为真空磁导率;Br和Bt分别为气隙磁通密度径向和切向分量,它们的傅里叶级数形式可表 示为

(2)

(2)

式中,Brm为m次径向气隙磁通密度谐波幅值,qrm为其相应的空间相位;Btn为n次切向气隙磁通密度谐波幅值,qtn为其相应的空间相位。因此,电磁转矩可根据式(3)计算。

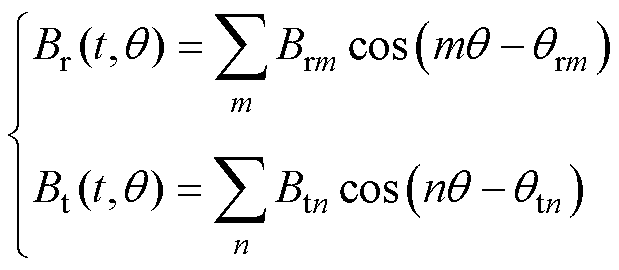

(3)

(3)

式中,l为积分路径;rg为气隙的积分半径;Lstk为电机轴向长度。由式(1)~式(3)可知,电磁转矩可进一步表示为

(4)

(4)

式中,Tk为k次气隙磁通密度谐波所产生的电磁 转矩。

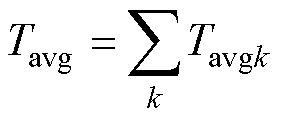

由式(4)可知,当且仅当径向与切向气隙磁通密度具有相同空间阶次,且其空间相位角度差不随时间变化时可产生稳定的电磁转矩。需要特别说明的是,式(4)获得的转矩为瞬态电磁转矩,因此获得一个完整电周期下的瞬态电磁转矩,即可得到其平均转矩,则总的平均转矩可表示为

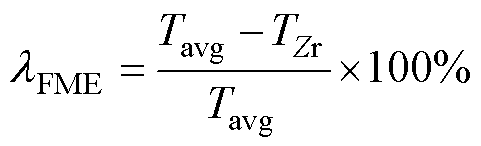

(5)

(5)

式中,Tavgk为k次气隙磁通密度谐波产生的平均 转矩。

式(5)表明,当获得了k次径向和切向气隙磁通密度分布时,其贡献的平均转矩即可由式(5)进行分离。因此,k次气隙磁通密度贡献的转矩分量在总转矩占比可表示为

(6)

(6)

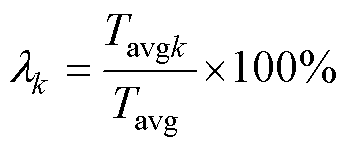

由上述分析可知,除Zr次主谐波外,其磁场调制谐波贡献的转矩占比表示为

(7)

(7)

式中,TZr为Zr次主谐波产生的平均转矩。

选择2对极永磁单元的表嵌式CPM电机与传统CPM结构进行对比,以确认转子调制齿数与永磁体极对数不等时带来的磁场非对称性。传统CPM和2对极永磁单元的非传统CPM结构如图4所示。由于电机磁饱和程度直接影响到气隙磁通密度谐波幅值,进而影响到气隙磁场调制效应,为进行公平比较,三个电机具有相同的定子结构、电负荷及永磁用量。需要指明的是,传统CPM电机转子永磁体极对数Zr与其转子调制齿数Zm相同,而非传统CPM电机转子调制齿数为其永磁体极对数的一半,即2对极永磁单元CPM电机调制齿数可表示为

图4 CPM电机结构

Fig.4 Machine topologies of the CPM machines

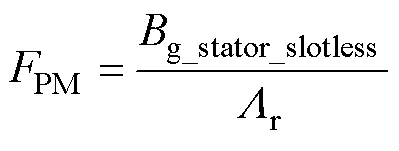

(8)

(8)

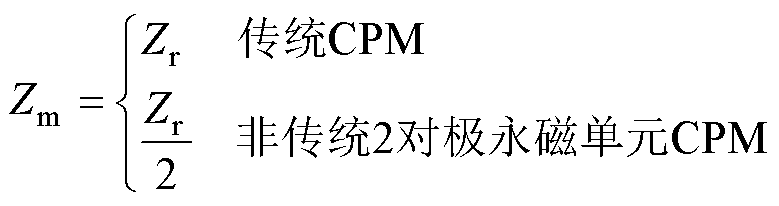

由有限元法获得定子无槽时CPM电机的气隙磁通密度及磁导[24],则其永磁体磁动势可表示为

(9)

(9)

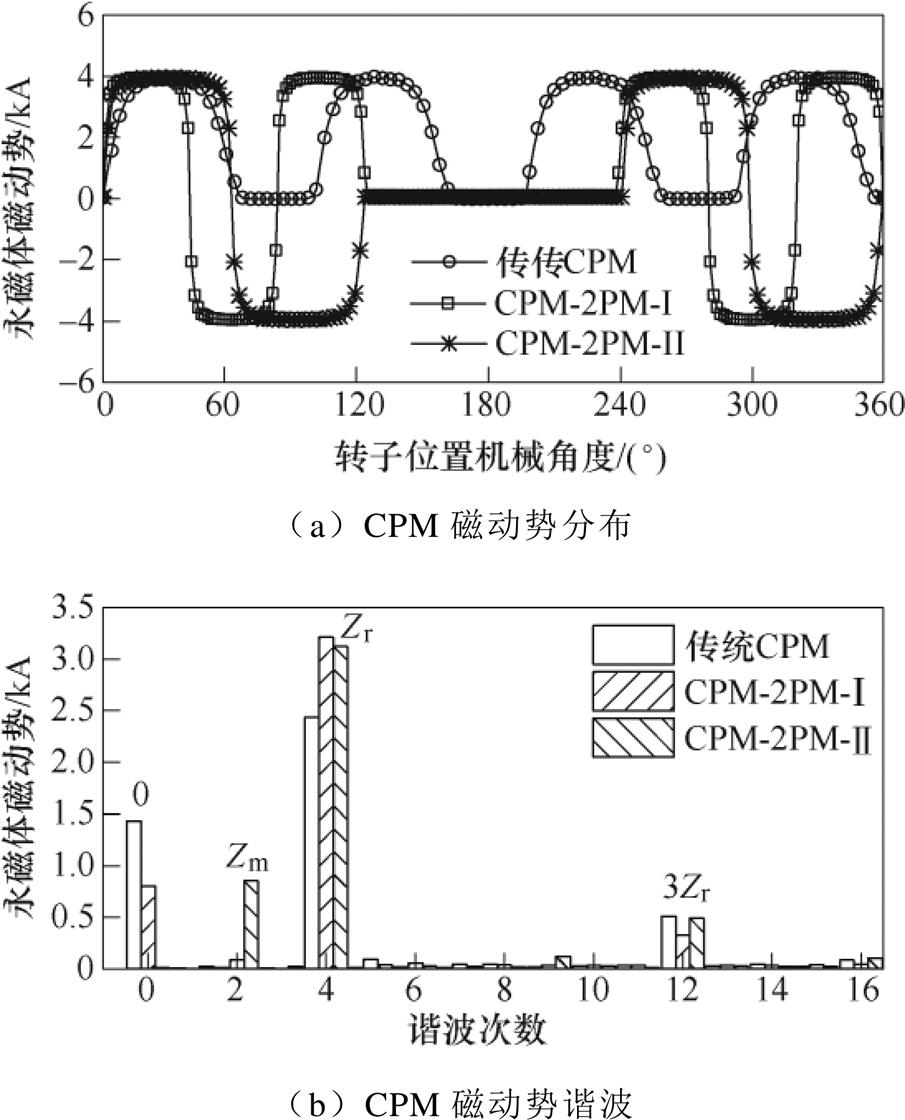

式中,Bg_stator_slotless为定子无槽时气隙磁通密度;Lr为定子无槽时气隙磁导。CPM电机磁动势如图5所示。分析可知,传统CPM结构磁动势呈4周期和单极性分布,故存在显著的Zr(4次)谐波及偏置磁动势分量,即0次磁动势谐波。此外,由于CPM-2PM-Ⅰ结构中磁动势不对称分布,故其除Zr(4次)谐波分量外,亦存在0次磁动势谐波。CPM-2PM-Ⅱ结构磁动势呈现对称性,且亦可视为2周期分布,故其存在显著的Zr(4次)和Zm(2次)谐波分量,且0次磁动势谐波极小,可忽略。

图5 CPM电机永磁体磁动势

Fig.5 PM magnetomotive forces of the CPM machines

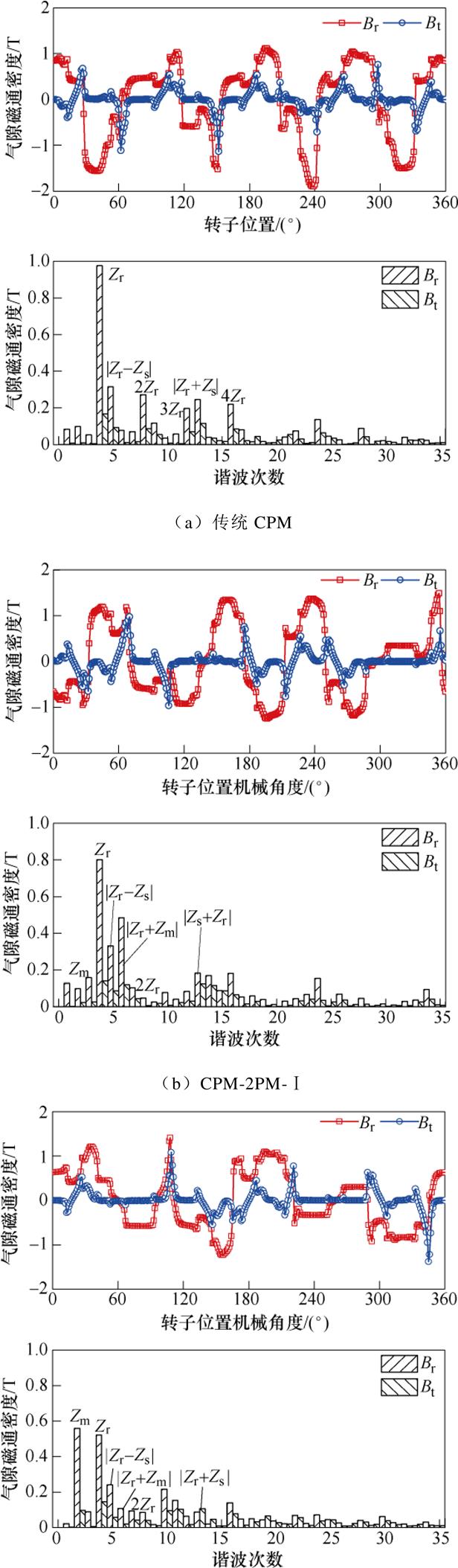

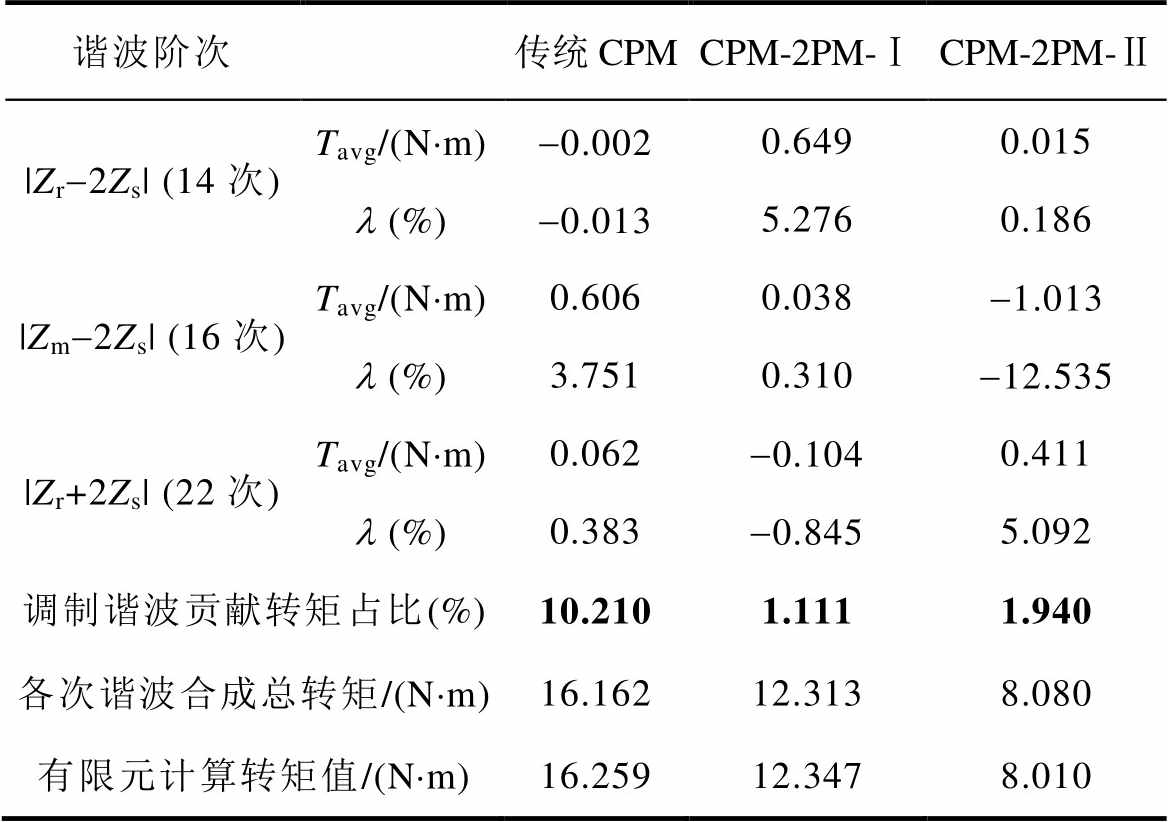

采用有限元法,获得三个CPM电机额定负载气隙磁通密度如图6所示。对比分析可知,非传统CPM电机中转子调制齿数与其永磁体极对数不等,导致其具有相对较低的Zr次谐波幅值。三种CPM结构均具有较多的调制谐波,如|Zr-Zs|(5次)、2Zr(8次)和|Zr+Zs|(13次),非传统CPM结构还存在Zm(2次)谐波。三个CPM电机气隙磁通密度主要谐波幅值见表1。对比分析可知,除定子齿调制作用可产生|Zr-Zs|(5次)、|2Zr-2Zs|(10次)、|Zr+Zs|(13次)、|Zr-2Zs|(14次)和|Zr+2Zs|(22次)谐波外,转子齿亦可调制产生Zm(2次)、|Zm-Zs|(7次)、|Zm+Zs|(11次)和|Zm-2Zs|(16次)谐波。此外,由于转子调制齿数与永磁体极对数不等,非传统CPM电机转子齿可调制出相对较高的Zm(2次)、|Zm-Zs|(7次)、|Zm+Zs|(11次)和|Zm-2Zs|(16次)谐波幅值。与传统CPM结果相比,非传统CPM结构Zr(4次)主谐波幅值相对较小,同时具有相对较高的Zm(2次)谐波幅值,表明非传统CPM结构转矩能力相对较低。

图6 CPM电机额定负载气隙磁通密度

Fig.6 Air-gap flux densities of the CPM machines at rated-load condition

表1 CPM电机额定负载气隙磁通密度主要谐波幅值

Tab.1 Main-order harmonic amplitudes of the air-gap flux densities in three CPM machines at rated-load (单位: T)

谐波阶次传统CPMCPM-2PM-ⅠCPM-2PM-Ⅱ Zr (4次)Br0.9760.8100.520 Bt0.1660.1390.145 Zm (2次)Br0.0970.1970.560 Bt0.0090.0230.096 |Zr-Zs| (5次)Br0.3140.3310.241 Bt0.0940.0860.058 |Zm-Zs| (7次)Br0.0710.1040.094 Bt0.0160.0440.042 2Zr (8次)Br0.2710.0470.086 Bt0.0870.0060.040 |2Zr-2Zs| (10次)Br0.0360.0780.216 Bt0.0080.0080.096 |Zm+Zs| (11次)Br0.0570.0610.153 Bt0.0050.0230.103 3Zr (12次)Br0.0560.0830.063 Bt0.0710.0310.017 |Zr+Zs| (13次)Br0.2460.1830.088 Bt0.1160.1250.106 |Zr-2Zs| (14次)Br0.0410.1680.020 Bt0.0350.1150.047 |Zm-2Zs| (16次)Br0.1180.1810.140 Bt0.0860.0960.087 |Zr+2Zs| (22次)Br0.0750.0440.068 Bt0.0310.0330.057

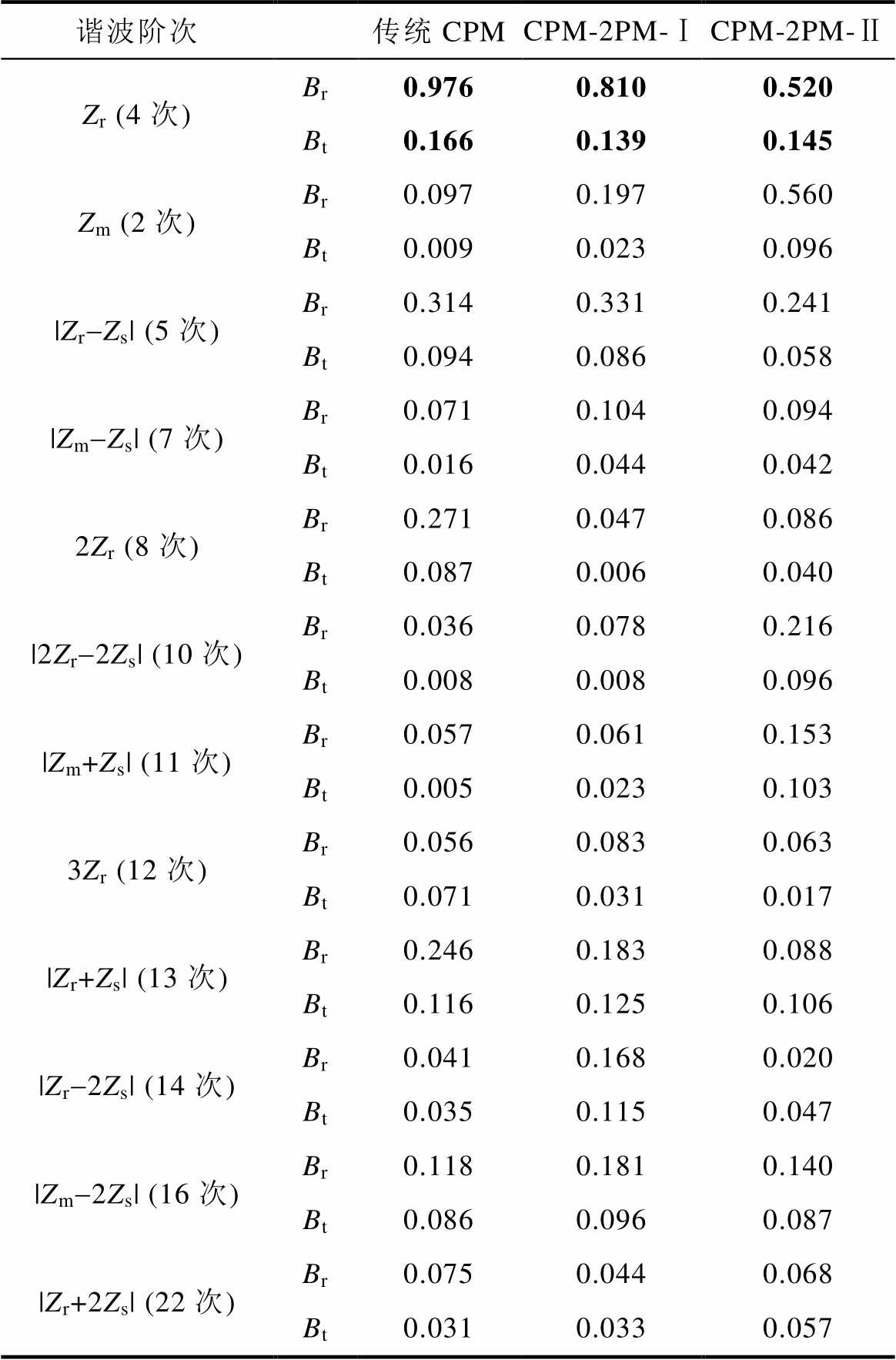

三个CPM电机空载下气隙磁通密度主要谐波幅值见表2。分析可知,由于双凸极气隙结构,三个CPM电机均可产生出丰富的气隙磁通密度调制谐波。此外,对比表1和表2可知,由于空载时仅有永磁体一种励磁源,其气隙磁通密度Zr(4次)、Zm(2次)、|Zr-Zs|(5次)、|Zm-Zs|(7次)、2Zr(8次)和|2Zr-2Zs|(10次)等谐波幅值略小于负载状态。

表2 CPM电机空载气隙磁通密度主要谐波幅值

Tab.2 Main-order harmonic amplitudes of the no-load air-gap flux densities in three CPM machines (单位: T)

谐波阶次传统CPMCPM-2PM-ⅠCPM-2PM-Ⅱ Zr (4次)Br0.9110.7780.511 Bt0.1530.1080.095 Zm (2次)Br0.0050.0530.534 Bt0.0020.0070.070 |Zr-Zs| (5次)Br0.2450.1480.110 Bt0.0590.0680.046 |Zm-Zs| (7次)Br0.0700.0380.032 Bt0.0050.0270.071 2Zr (8次)Br0.1990.0410.096 Bt0.0590.0050.013 |2Zr-2Zs| (10次)Br0.0140.0090.208 Bt0.0070.0130.066 |Zm+Zs| (11次)Br0.0190.0320.135 Bt0.0160.0220.113 3Zr (12次)Br0.2680.0350.010 Bt0.0800.0320.017 |Zr+Zs| (13次)Br0.284.01600.123 Bt0.1100.1270.093 |Zr-2Zs| (14次)Br0.0770.2370.064 Bt0.0380.0800.037 |Zm-2Zs| (16次)Br0.2200.1490.191 Bt0.0750.0580.023 |Zr+2Zs| (22次)Br0.0500.0530.064 Bt0.0210.0370.053

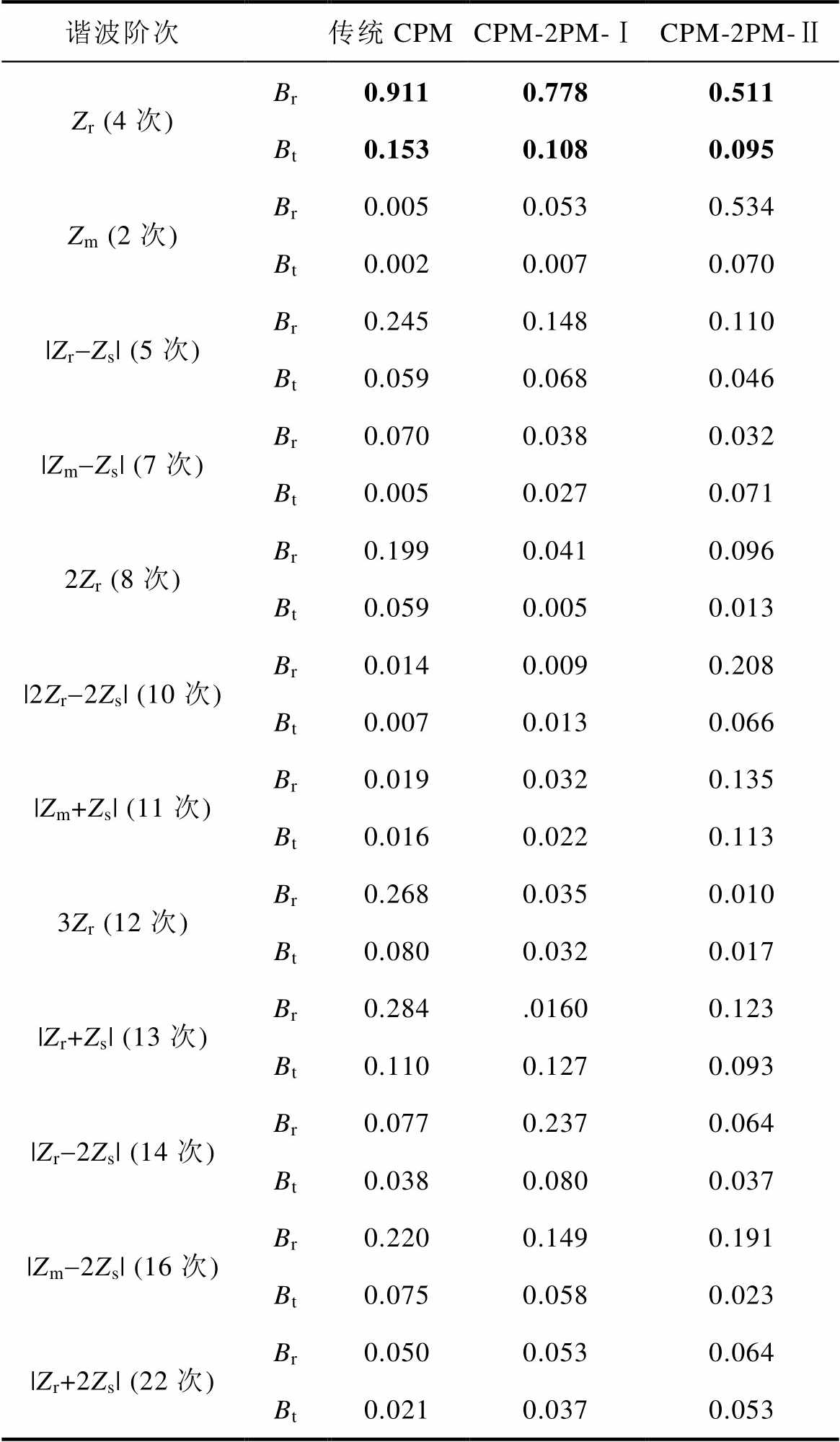

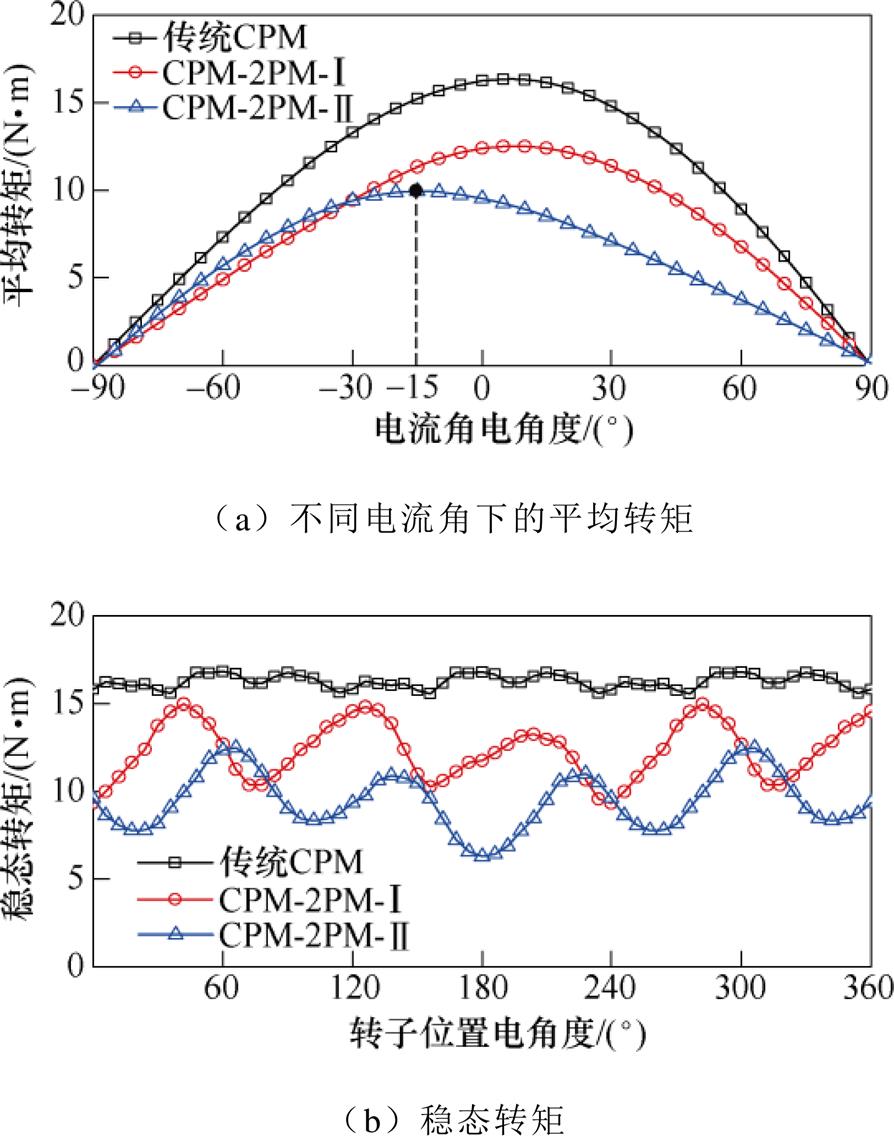

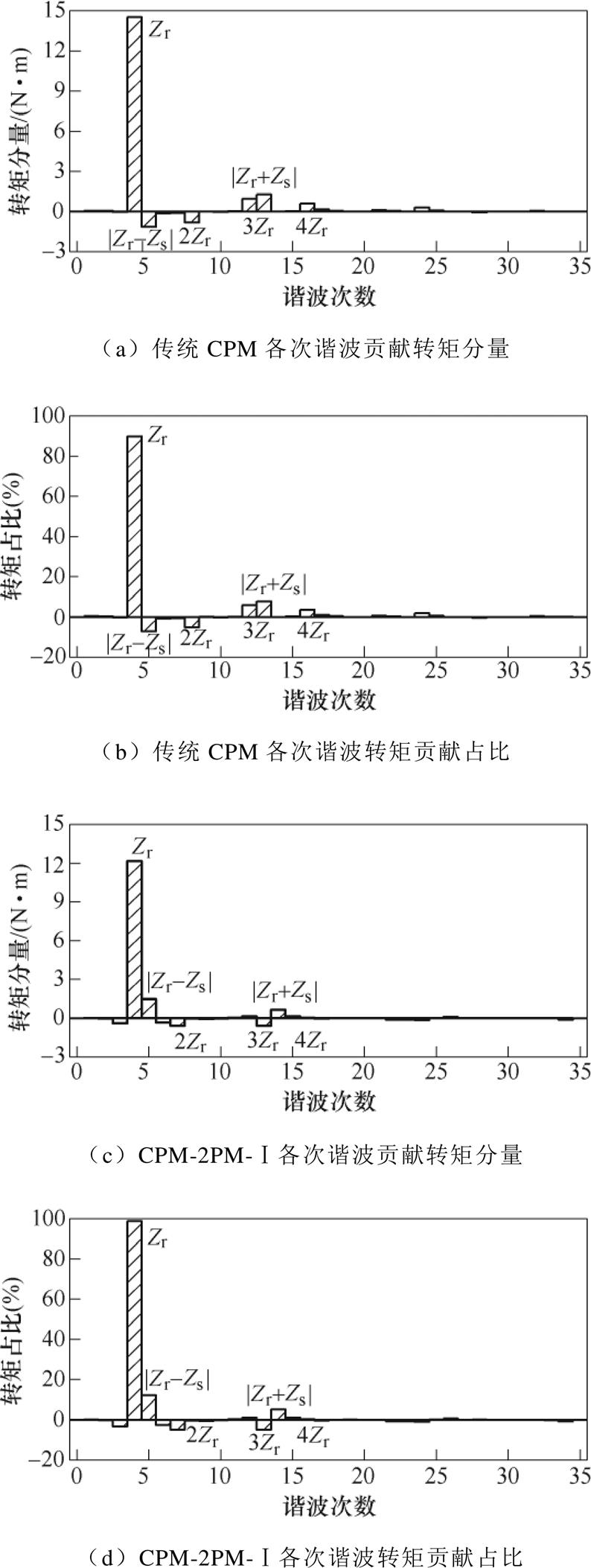

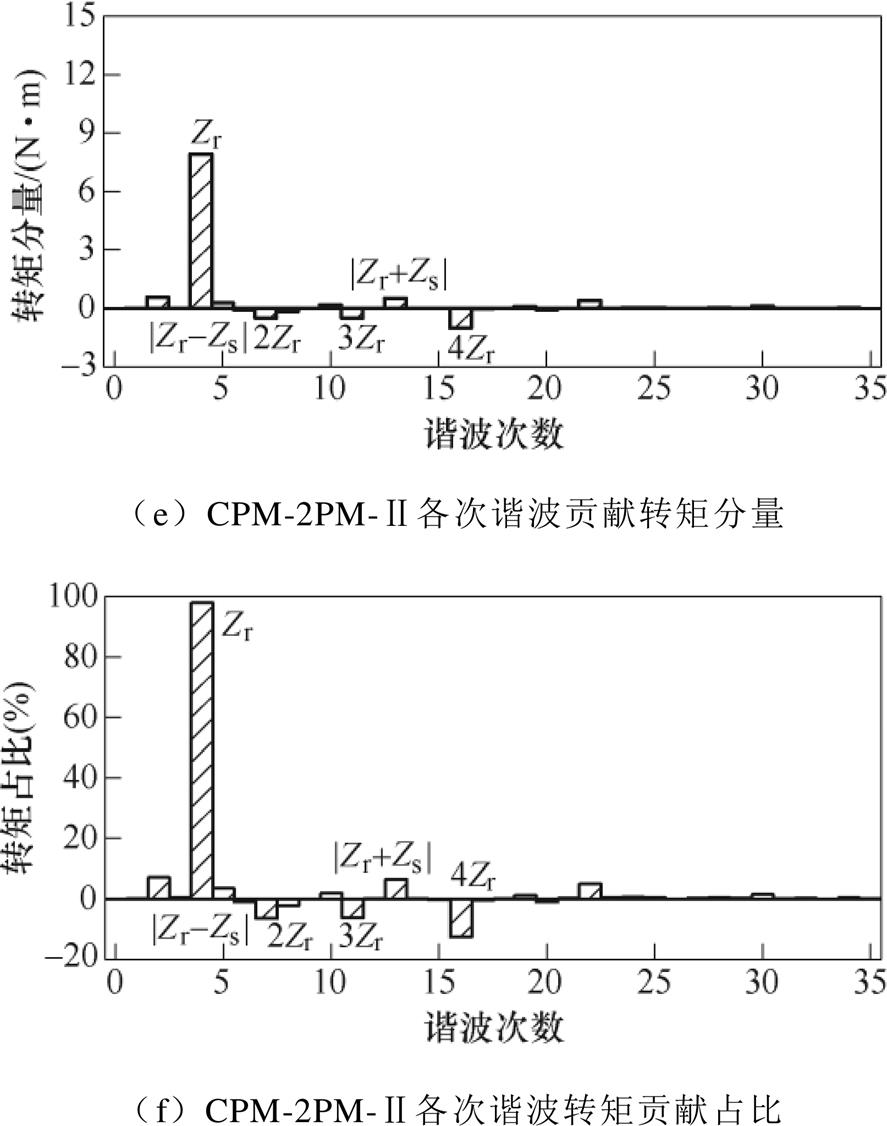

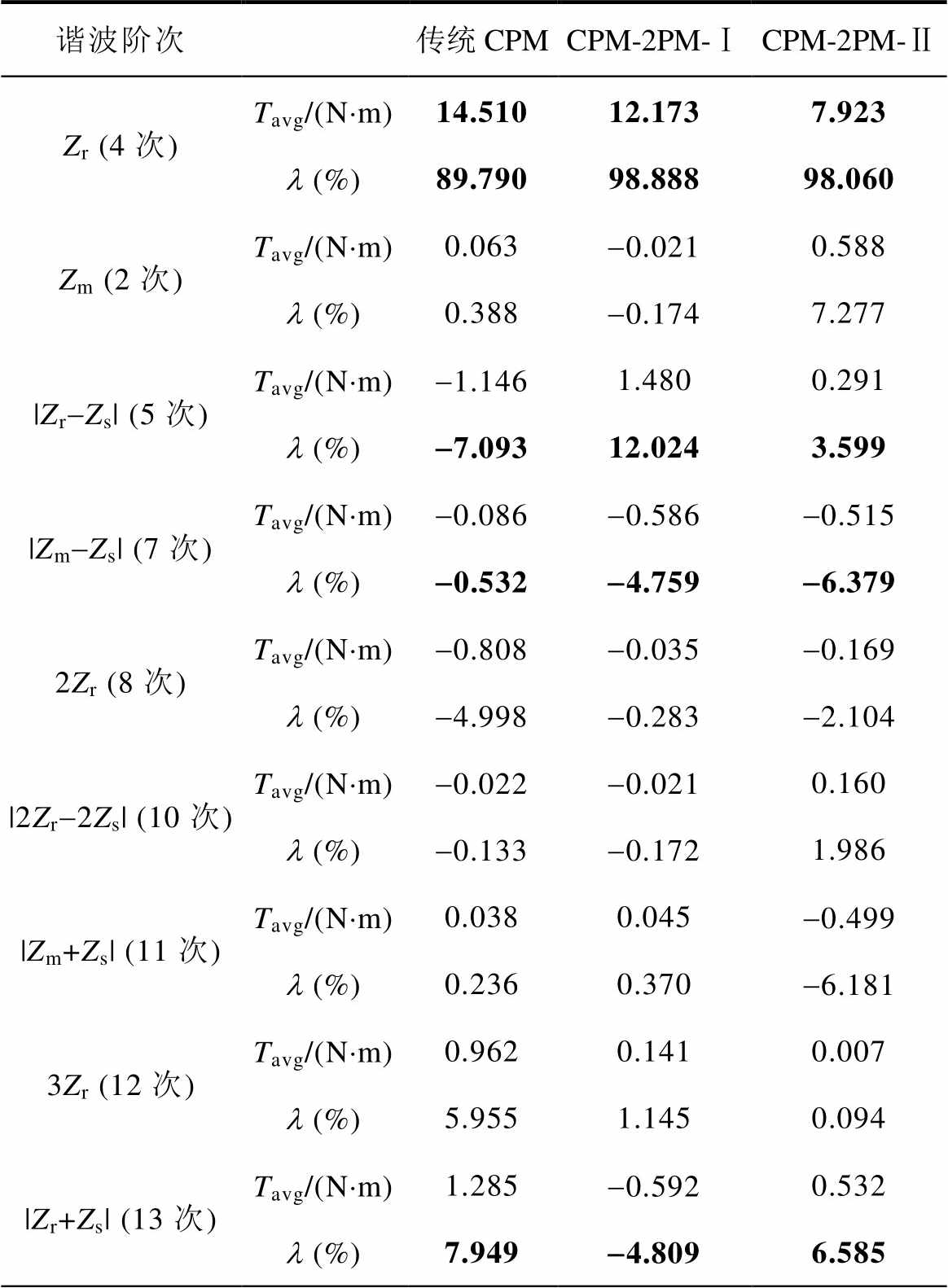

三个CPM电机转矩特性如图7所示,分析可知,传统结构和CPM-2PM-Ⅰ电机均在零度电流角时取得最大值,即表明其磁阻转矩极低,可忽略。而CPM-2PM-Ⅱ结构呈现出反凸极现象,即电流角为-15°时取得最大转矩值。对比分析可知,由于传统CPM结构转子调制齿数与永磁体极对数相同,其主谐波幅值相对较高,因此其具有相对较高的转矩输出能力。由式(1)~式(7)对三个电机气隙磁通密度各次谐波转矩贡献进行量化分析,如图8所示。分析可知,三种CPM电机均存在多种谐波贡献转矩,表明均存在气隙磁场调制效应。与传统结构相比,非传统CPM结构具有相对较低的主谐波幅值,因此其主谐波贡献了相对较低的转矩分量,从而使其总的合成转矩低于传统CPM电机,这表明非传统CPM电机未能充分利用主谐波提升电机转矩能力。三个电机各次谐波转矩贡献见表3。对比分析可知,与其他调制谐波相比,传统CPM结构中的|Zr-Zs|(5次)、2Zr(8次)、|Zr+Zs|(13次)调制谐波贡献了相对较大的转矩占比,而非传统CPM结构中除|Zr-Zs|(5次)、2Zr(8次)、|Zr+Zs|(13次)谐波外,还有Zm(2次)、|Zm+Zs|(7次)和|Zm-2Zs|(16次)谐波贡献了相对较多的转矩分量。与传统结构CPM电机相比,尽管非传统CPM结构展现出相对较多的调制谐波贡献转矩,但其主谐波Zr(4次)贡献了相对较高的转矩占比,导致其调制效应贡献转矩占比相对较低,即其调制谐波贡献转矩占比低于2 %,因此非传统CPM结构磁场调制效应基本可忽略。此外,由于只考虑了35阶以内的主要气隙磁通密度谐波,三个电机的各次谐波转矩贡献之和均略小于有限元仿真值,但其差值极小,即表明气隙磁通密度谐波转矩贡献量化的准 确性。

以传统CPM结构为基准,对转子调制齿数与永磁体极对数不等的非传统CPM电机气隙磁通密度谐波转矩贡献进行量化分析可知,非传统CPM电机具有以下典型特征:

图7 CPM电机转矩特性

Fig.7 Torque characteristics of the CPM machines

图8 传统CPM和2对极永磁单元的非传统CPM电机各次谐波转矩贡献

Fig.8 Torque contributions of the conventional CPM and unconventional CPM machines with two pole-pair PMs

表3 CPM电机主要工作谐波转矩贡献

Tab.3 Torque contributions of the main-order working harmonics in CPM machines

谐波阶次传统CPMCPM-2PM-ⅠCPM-2PM-Ⅱ Zr (4次)Tavg/(N×m)14.51012.1737.923 l (%)89.79098.88898.060 Zm (2次)Tavg/(N×m)0.063-0.0210.588 l(%)0.388-0.1747.277 |Zr-Zs| (5次)Tavg/(N×m)-1.1461.4800.291 l (%)-7.09312.0243.599 |Zm-Zs| (7次)Tavg/(N×m)-0.086-0.586-0.515 l (%)-0.532-4.759-6.379 2Zr (8次)Tavg/(N×m)-0.808-0.035-0.169 l (%)-4.998-0.283-2.104 |2Zr-2Zs| (10次)Tavg/(N×m)-0.022-0.0210.160 l (%)-0.133-0.1721.986 |Zm+Zs| (11次)Tavg/(N×m)0.0380.045-0.499 l (%)0.2360.370-6.181 3Zr (12次)Tavg/(N×m)0.9620.1410.007 l (%)5.9551.1450.094 |Zr+Zs| (13次)Tavg/(N×m)1.285-0.5920.532 l (%)7.949-4.8096.585

(续)

谐波阶次传统CPMCPM-2PM-ⅠCPM-2PM-Ⅱ |Zr-2Zs| (14次)Tavg/(N×m)-0.0020.6490.015 l (%)-0.0135.2760.186 |Zm-2Zs| (16次)Tavg/(N×m)0.6060.038-1.013 l (%)3.7510.310-12.535 |Zr+2Zs| (22次)Tavg/(N×m)0.062-0.1040.411 l (%)0.383-0.8455.092 调制谐波贡献转矩占比(%)10.2101.1111.940 各次谐波合成总转矩/(N×m)16.16212.3138.080 有限元计算转矩值/(N×m)16.25912.3478.010

(1)非传统CPM电机转子调制齿数与永磁体极对数不等时,未能充分利用0次永磁磁动势和Zr次转子磁导来提高主谐波(Zr次)幅值,导致其主谐波幅值相对较低,转矩能力亦随之相对较低。

(2)非传统CPM电机具有相对较为丰富的气隙磁场调制谐波贡献转矩,但由于其主谐波贡献转矩占比相对较大,导致其磁场调制谐波贡献转矩占比相对较低。

(3)非传统CPM电机转子调制齿数与永磁体极对数不等时,虽可调制出相对较多的气隙磁场谐波,但其气隙磁场调制谐波贡献的转矩值有正有负,导致非传统CPM结构调制谐波贡献的总转矩占比反而有所降低。

(4)与转子调制齿和永磁体相等的传统CPM结构相比,转子调制齿数与永磁体极对数不等时调制的气隙磁场谐波贡献转矩贡献占比极低,可忽略,因此转子调制齿数与永磁体极对数不等时的非传统CPM电机可视为仅有主谐波贡献平均转矩的传统电机。

此外,将上述转子调制齿数与永磁体极对数不等的非传统表嵌式CPM结构延伸到内嵌式结构中,亦可获得各种不同永磁结构的非传统内嵌式CPM电机。但由于其未根本改变永磁体磁动势和转子磁导的谐波阶次相匹配的关系,使其未能充分利用偏置磁动势来提高其主谐波幅值及转矩输出能力,因此非传统内嵌式CPM电机亦可获得与表嵌式结构相似的结论,本文在此不再赘述。

此外,还需指明的是,虽然非传统CPM电机的转子调制齿数与永磁体极对数不等,导致其主谐波及转矩能力相对较低,但其可利用非传统结构永磁体特殊排列方式来实现CPM电机的不平衡磁拉力[25]、振动噪声[25]、轴电压[26-27]等其他性能的改善。

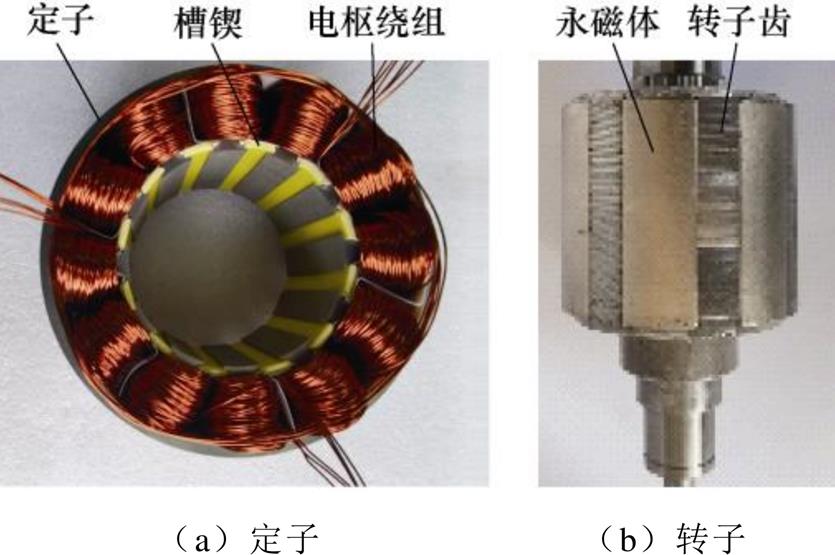

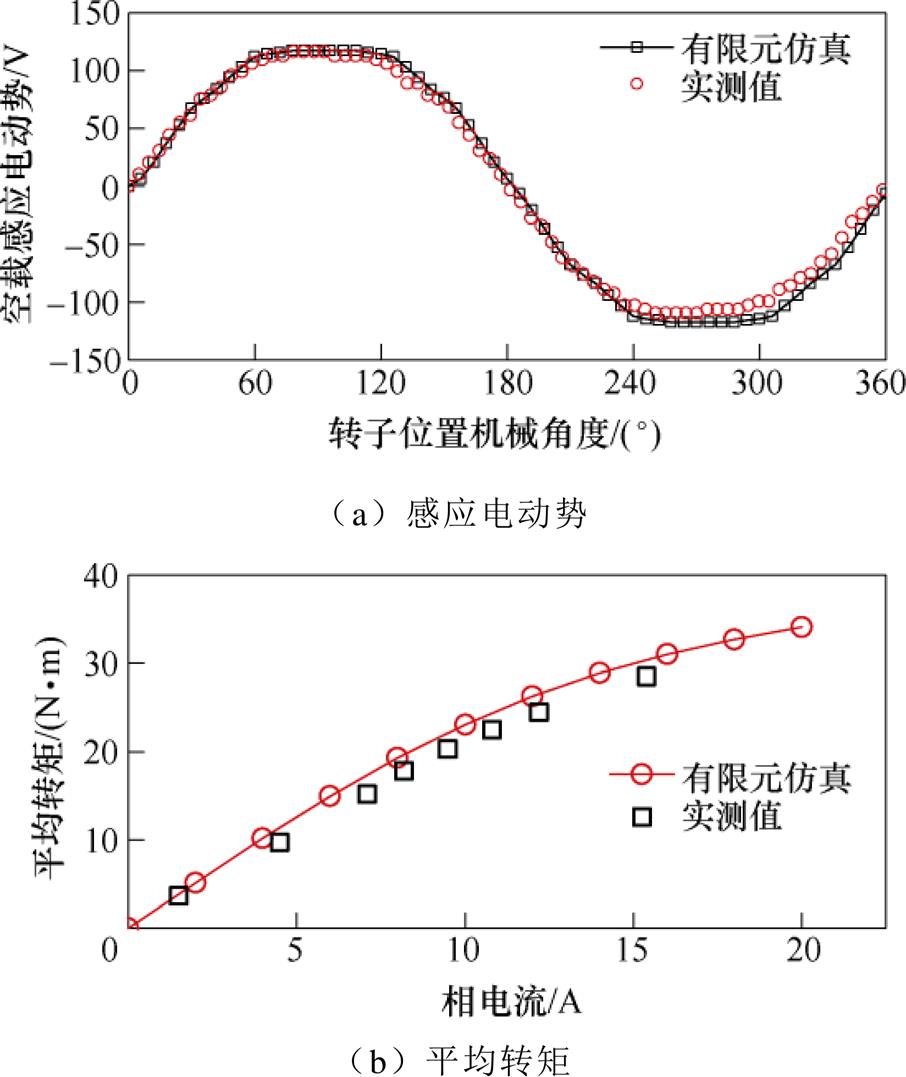

为验证上述分析,制作了一台CPM样机,如图9所示。对样机空载感应电动势及不同电流下的平均转矩进行测试,样机实测值与有限元仿真结果对比分析如图10所示。由于二维有限元仿真忽略了电机端部效应,且样机加工存在一定的机械误差,实测值略小于有限元仿真结果。但实测值与仿真结果基本吻合,这也验证了仿真的可靠性。

图9 CPM样机

Fig.9 Prototype of the CPM machine

图10 样机实测与有限元仿真值对比

Fig.10 Comparison of the tested and FE simulated results

本文探究了表嵌式CPM电机不同永磁结构拓扑演化规律,总结了永磁体极对数与转子调制齿数之间的内在联系。并采用MSTM量化分析了气隙磁通密度各次谐波转矩贡献,表明永磁体极对数与转子调制齿数对气隙磁场调制谐波转矩贡献影响较大。最后,加工了样机并开展了试验研究,验证了理论分析与有限元仿真的可靠性。

参考文献

[1] 黄海林, 李大伟, 曲荣海, 等. 磁齿轮复合永磁电机拓扑及应用综述[J]. 电工技术学报, 2022, 37(6): 1381-1397.

Huang Hailin, Li Dawei, Qu Ronghai, et al. A review of magnetic geared machines: topologies and appli- cations[J]. Transactions of China Electrotechnical Society, 2022, 37(6): 1381-1397.

[2] 罗俊, 寇宝泉, 杨小宝. 双交替极横向磁通直线电机的优化与设计[J]. 电工技术学报, 2020, 35(5): 991-1000.

Luo Jun, Kou Baoquan, Yang Xiaobao. Optimization and design of dual-consequent-pole transverse flux linear machine[J]. Transactions of China Electro- technical Society, 2020, 35(5): 991-1000.

[3] Li Ya, Yang Hui, Lin Heyun, et al. Investigation of double-side field modulation mechanism in consequent- pole PM machines with concentrated windings[J]. IEEE Transactions on Energy Conversion, 2021, 36(3): 1635-1648.

[4] Li J, Wang K, Liu C. Torque improvement and cost reduction of permanent magnet machines with a dovetailed consequent-pole rotor[J]. IEEE Transa- ctions on Energy Conversion, 2018, 33: 1628-1640.

[5] 许孝卓, 孙震, 汪旭东, 等. Halbach交替极永磁同步直线电机特性分析[J]. 电工技术学报, 2019, 34(9): 1825-1833.

Xu Xiaozhuo, Sun Zhen, Wang Xudong, et al. Characteristic of a novel permanent magnet linear synchronous motor with Halbach array consequent- pole[J]. Transactions of China Electrotechnical Society, 2019, 34(9): 1825-1833.

[6] Watahiki T, Toriumi Y, Miki I. A consequent pole motor with novel pole structure[C]//IEEE 2018 Inter- national Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy: 1136-1140.

[7] Wu Leilei, Qu Ronghai. Comparison of conventional and consequent pole interior permanent magnet machines for electric vehicle application[C]//IEEE 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 70-74.

[8] 樊英, 谭超. 内置式交替极永磁同步电机性能及机理研究[J]. 电工技术学报, 2018, 33(11): 2414-2422.

Fan Ying, Tan Chao. Analysis of electromagnetic performance and principles in inserted consequent- pole permanent magnet synchronous machines[J]. Transactions of China Electrotechnical Society, 2018, 33(11): 2414-2422.

[9] Chiu M T, Chiang J A, Lin C H. Design and optimi- zation of a novel V-type consequent-pole interior permanent magnet synchronous motor for applying to refrigerant compressor[C]//2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea (South), DOI: 10.23919/ICEMS. 2018. 8549357.

[10] Kolehmainen J. Optimal dovetail permanent magnet rotor solutions for various pole numbers[J]. IEEE Transactions on Industrial Electronics, 2010, 57(1): 70-77.

[11] 许孝卓, 封海潮, 艾立旺, 等. U型永磁凸极直线电机结构及电磁特性[J]. 电工技术学报, 2021, 36(6): 1179-1189.

Xu Xiaozhuo, Feng Haichao, Ai Liwang, et al. Structure and electromagnetic characteristics of U-shaped permanent magnet salient pole linear motor[J]. Transactions of China Electrotechnical Society, 2021, 36(6): 1179-1189.

[12] Liu Wenbo, Lipo T A. Analysis of consequent pole spoke type vernier permanent magnet machine with alternating flux barrier design[J]. IEEE Transactions on Industry Applications, 2018, 54(6): 5918-5929.

[13] 梁子漪, 曲荣海, 李大伟, 等. 一种交替极切向励磁游标永磁电机的分析与设计[J]. 电工技术学报, 2020, 35(15): 3173-3181.

Liang Ziyi, Qu Ronghai, Li Dawei, et al. Analysis of a consequent-pole spoke-array vernier permanent magnet machine[J]. Transactions of China Elect- rotechnical Society, 2020, 35(15): 3173-3181.

[14] Palomo R E Q, Gwozdziewicz M. Effect of demag- netization on a consequent pole IPM synchronous generator[J]. Energies, 2020, 13(23): 6371.

[15] Zhang Lin, Wang Kai, Li Jian, et al. Comparison study of interior permanent magnet synchronous machine with conventional and consequent pole rotor[C]//2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, 2019: 1-5.

[16] Wang K, Li J, Zhu S S, et al. Novel hybrid-pole rotors for consequent-pole PM machines without unipolar leakage flux[J]. IEEE Transactions on Industrial Electronics, 2019, 66(9): 6811-6823.

[17] Dajaku G. Open-circuit air-gap field calculation of a new PM machine having a combined SPM and spoke- type magnets[J]. IEEE Transactions on Magnetics, 2020, 56(6): 1-9.

[18] Xu Gaohong, Zhao Wenxiang, Liu Guohai, et al. Torque performance improvement of consequent-pole PM motors with hybrid rotor configuration[J]. IEEE Transactions on Transportation Electrification, 2021, 7(3): 1561-1572.

[19] Li Dawei, Qu Ronghai, Li Jian. Topologies and analysis of flux-modulation machines[C]//2015 IEEE Energy Conversion Congress and Exposition, Montreal, QC, Canada, 2015: 2153-2160.

[20] Chen Yiduan, Fu Weinong, Weng Xu. A concept of general flux-modulated electric machines based on a unified theory and its application to developing a novel doubly-fed dual-stator motor[J]. IEEE Transa- ctions on Industrial Electronics, 2017, 64(12): 9914- 9923.

[21] Cheng Ming, Han Peng, Hua Wei. General airgap field modulation theory for electrical machines[J]. IEEE Transactions on Industrial Electronics, 2017, 64(8): 6063-6074.

[22] 程明, 文宏辉, 曾煜, 等. 电机气隙磁场调制行为及其转矩分析[J]. 电工技术学报, 2020, 35(5): 921- 930.

Cheng Ming, Wen Honghui, Zeng Yu, et al. Analysis of airgap field modulation behavior and torque component in electric machines[J]. Transactions of China Electrotechnical Society, 2020, 35(5): 921-930.

[23] Zhu W, Pekarek S, Fahimi B, et al. Investigation of force generation in a permanent magnet synchronous machine[J]. IEEE Transactions on Energy Conversion, 2007, 22(3): 557-565.

[24] Huang L R, Feng J H, Guo S Y, et al. Analysis of torque production in variable flux reluctance machines[J]. IEEE Transactions on Energy Con- version, 2017, 32(4): 1297-1308.

[25] Zhu Shengdao, Ji Jinghua, Zhao Wenxiang, et al. Vibration reduction design of consequent pole PM machine by symmetrizing local and global magnetic field[J]. IEEE Transactions on Industrial Electronics, 2023, 70(1): 243-254.

[26] Li J, Wang K, Li F, et al. Elimination of even-order harmonics and unipolar leakage flux in consequent- pole PM machines by employing N-S-iron–S-N-iron rotor[J]. IEEE Transactions on Industrial Electronics, 2019, 66(3): 1736-1747.

[27] Li J, Wang K, Liu C, et al. Elimination of unipolar leakage flux in consequent-pole PM machines by employing novel pole sequence[J]. IEEE Transactions on Magnetics, 2018, 54(11): 1-5.

Abstract Compared with traditional surfaced-mounted permanent magnet (SPM) machine, the consequent- pole permanent magnet (CPM) structures show a higher permanent magnet (PM) utilization ratio and comparable torque capability. Thus, the various PM arrangements are developed and studied in recent years. However, the corresponding topology evolution and the underlying air-gap field modulation (AGFM) mechanism are unrevealed. To present an in-depth understanding of their torque production principle, the topology evaluation and their AGFM effect in the surface-inset CPM machines were investigated and compared.

Firstly, topology evaluation of the CPM machines with different PM arrangements was illustrated by adopting PM unit concept. According to their relationship of the rotor modulated teeth and PM pole-pair number, the CPM machines with different pole-pair PMs in a PM unit was developed. Different from conventional CPM configurations share with same PM pole-pair and rotor modulated teeth, the unconventional CPM machines have the unequal number of the PM pole-pair and rotor modulated teeth. Some topological evolution rules can be summarized as: (1) When n (≥2) pole-pair of PMs are included in a PM unit, n typical non-traditional CPM structures can be formed. (2) An unconventional CPM machine with n (≥2) pole-pair of PMs in a PM unit, the maximum number of the rotor modulated teeth is n-1. (3) Because the S pole (or N pole) and the adjacent N and S poles in a PM unit can be replaced by the rotor iron teeth, there are two types of non-traditional CPM structures can be formed when the rotor modulation tooth is 1 in a PM unit.

To identify the different PMarrangement on their air-gap magnetic field, torque contributions of the various air-gap field harmonics were quantified by Maxwell Stress Tensor method (MSTD). The simulation results show that various air-gap field modulated harmonics are responsible for torque generation in three typical CPM machines, which implies that the pronounced AGFM effect can be obtained in conventional and unconventional CPM cases. Besides, compared with other modulated field harmonics, the |Zr-Zs| (5th), 2Zr (8th) and |Zr+Zs|(13rd) contributes a relatively higher torque components in conventional CPM machine. However, apart from the |Zr-Zs| (5th), 2Zr (8th) and |Zr+Zs|(13rd), the Zm (2nd)、|Zm+Zs| (7th) and |Zm-2Zs| (16th) are also participating in torque production. Although more air-gap field harmonics are responsible for torque generation in unconventional CPM structure, its total torque proportion of the modulated field harmonics is lower than the conventional CPM case. This is mainly due to the relatively lower amplitudes of the Zr (4th) air-gap flux density in unconventional CPM machines. To confirm the abovementioned analysis, a CPM machine prototype was manufactured. Some tested results on the open-circuit back-EMF and electromagnetic torques were measured and compared with simulations, which verifies the effectiveness of the theoretical and simulated analyses.

Some conclusions can be drawn from the simulation and experimental analyses: (1) Because of the unequal number of the PM pole-pair and rotor modulated teeth, the unconventional CPM machines exhibits a relatively lower Zr order air-gap flux density and hence resulting a lower torque capability. (2) Although various air-gap field harmonics can be modulated in unconventional CPM structure, the total torque proportion of the modulated field harmonics is less than 2 %, which indicates that the unconventional CPM machine can be seen as a typical traditional PM synchronous machine with only one working harmonic for torque generation. (3) Due to the higher torque proportion of the air-gap field modulation harmonics, the conventional CPM machines show a pronounced AGFM effect than unconventional counterparts.

keywords:Air-gap field modulation effect, consequent-pole, permanent magnet machine, torque quanti- fication

DOI: 10.19595/j.cnki.1000-6753.tces.220984

中图分类号:TM351

国家自然科学基金项目(51607001, 52177027, 52107034)、安徽省自然科学基金优秀青年项目(2108085Y18)、安徽省高校优秀青年人才重点项目(gxyqZD2021090)和安徽省重大科技专项(202203c08020010)资助。

收稿日期 2022-05-31

改稿日期 2022-06-15

李 亚 男,1991年生,博士,研究方向为电机设计及其控制。E-mail: yali@ahu.edu.cn

丁石川 男,1980年生,教授,博士生导师,研究方向为高品质电机及驱动系统设计与控制、故障诊断、容错控制。E-mail: dsc@ahu.edu.cn(通信作者)

(编辑 郭丽军)